Cast finish.

How to restore it?

| Bo'sun | 13/08/2022 17:15:18 |

| 754 forum posts 2 photos | Good afternoon, I'm building a small Traction Engine that uses several aluminium castings. Clearly they needed to be fettled, which I've done. Is there a way to restore the cast surface finish where the fettling has taken place. I don't have, or even access to a blast cabinet. Thanks. |

| pgk pgk | 13/08/2022 17:31:45 |

| 2661 forum posts 294 photos | I’ve not tried it but you can get cheapish sandblasting attachments for a compressor and knock up some sort of box to try and recycle some of the grit?

|

| lee webster | 13/08/2022 17:41:10 |

| 383 forum posts 71 photos | Hi Bo'sun, I've not tried this myself but I wondered if some coarse tough emery cloth glued to a hammer head and then tap the surface to speckle it. It would, of course, only work on surfaces you can get a hammer to. |

| ChrisLH | 13/08/2022 17:42:50 |

| 111 forum posts 7 photos | Professor Chaddock made his carved from solid engine crankcase look like a casting by grit blasting with home made kit. You do however need a compressed air supply to make it work. Relevant ME articles p. 456 05/05/ 67 and p. 515 19/05/67. If you don't have access, PM me and I will provide scans by email. |

| JasonB | 13/08/2022 17:55:53 |

25215 forum posts 3105 photos 1 articles | If you scaled down a full size grain of sand to suit your small traction engine then you really don't want any noticible texture. If you must then the old Wolf engraving tools can be quite good at adding back texture in the larger scales or even holding a dot punch in your fingers and doing similar manually has worked for me. On fabricated work that I want to look like it was cast I tend to file off the external corners and then just run the side of a Dremel grinding point over the flat surfaces more to make them a little uneven than to add texture. I also do this to castings to reduce the texture left by the sand. I've not found blasting to add texture to smooth areas, at least not enough to replicate a coarse cast one. Grit or bead blasting on aluminium tends to give more a die cast finish than sand cast, I use it to give a uniform finish after tooling marks have been removed with emery which leaves directional marks. |

| JasonB | 13/08/2022 18:03:27 |

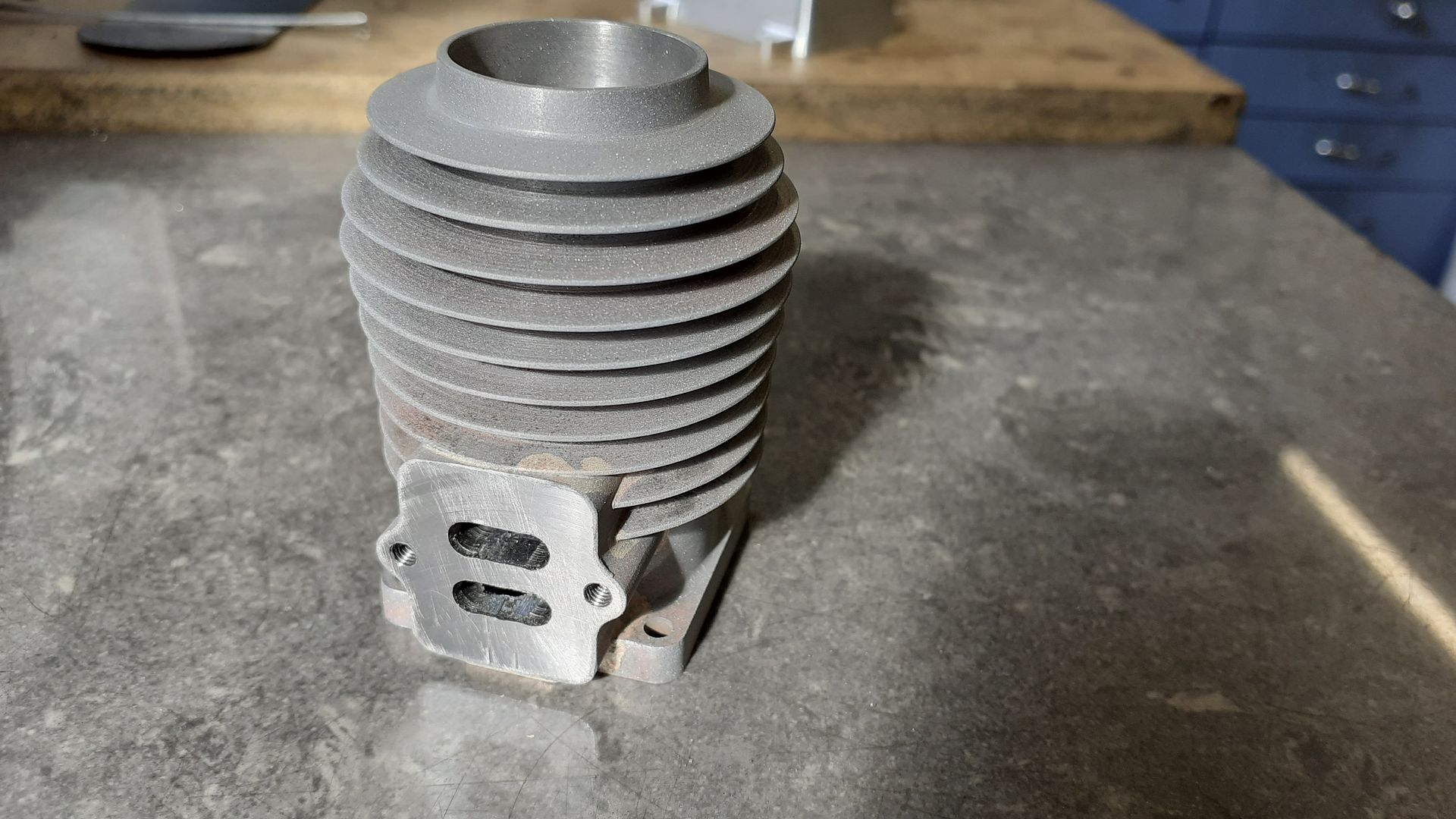

25215 forum posts 3105 photos 1 articles | This is a grit blasted steel cylinder fabrication, done to clean up after soldering more to texture but it only leaves a fine surface texture more like 180g abrasive than sand would leave on a casting and once painted won't show. Iron would come up with the same sort of finish

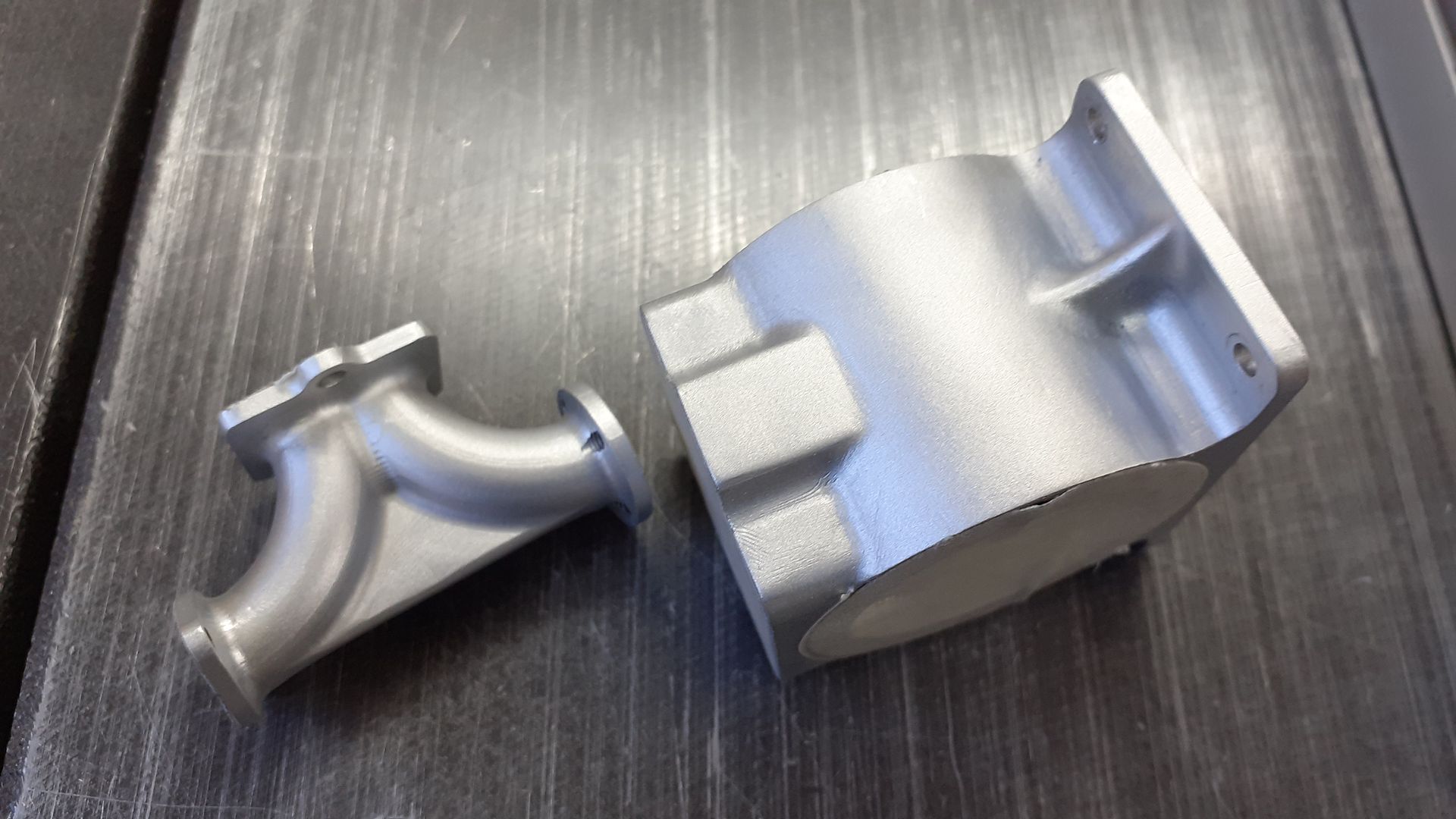

This is bead blasted aluminium, just a nice satin finish that is quite uniform again if you painted it you would not know it had been done.

This post of mine shows the effect of the Dremel and that is on a 1/2 scale model not a small one.

|

| Trevor Drabble | 13/08/2022 18:45:20 |

339 forum posts 7 photos | Maybe try gentle pecking using fine carbide or diamond tools in a Dremel type tool ? Chronos do good ranges of both. I got my diamond ones from them and the carbide ones from JB Tooling , who l believe will be at the Midlands Show in October . |

| Ramon Wilson | 13/08/2022 22:49:18 |

1655 forum posts 617 photos | I used a mounted stone point at slow speed to achieve the effect on this aluminium crankcase

It could be painted over I guess but I chose to bead blast it to achieve the kind of impression of the original I was hoping for. This was not a casting but machined from solid but the effect would be similar.

I have also used an engraver to dimple the surface of bronze to give a cast impression The tool needs to be blunt, not a sharp point for the best effect. Here's another example on a home made valve body.

Hope that's of use - Tug Edited By Ramon Wilson on 13/08/2022 22:54:12 |

| JasonB | 14/08/2022 06:55:40 |

25215 forum posts 3105 photos 1 articles | Interesting to compare the "cast" valve with the painted casting behind in Ramon's last photo. Can't quite remember the scale of his diagonal engine maybe 1/12th but once painted it's effectively smooth and I would assume you want to paint the traction engine model. Is it a Wells? |

| Neil Lickfold | 14/08/2022 09:51:57 |

| 1025 forum posts 204 photos | I have used emery tape and the leather side of a copper rawhide hammer. It did match quite well to the casting surface around the fettled area. |

| Bo'sun | 14/08/2022 10:53:28 |

| 754 forum posts 2 photos | Thanks all, Plenty to be experimenting with. The surfaces will eventually be painted, so there is some tolerance, but I'm mindful not try and disguise the fettling by the over zealous application of paint. |

| Jon Lawes | 14/08/2022 12:03:09 |

1078 forum posts | I wonder how the model tank boys achieve the Zimmerit look? |

| JasonB | 14/08/2022 12:58:14 |

25215 forum posts 3105 photos 1 articles | Thin layer of putty and then poke it with a flat bladed tool in vertical rows. They also use the slow Dremel for texturing flate armor plate |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in