Harmonic drive.. Because I need another project...

| sam sokolik | 26/01/2021 16:38:12 |

| 126 forum posts | Thought this would be a neat experiment to see if a minimally printed harmonic drive would work (for some definition of..) Just printing the flex and outside gear.

|

| Martin Connelly | 26/01/2021 18:01:19 |

2549 forum posts 235 photos | Some torque wrenches have plastic harmonic drives in the adjusting mechanism to drive the scale round. Martin C |

| sam sokolik | 28/01/2021 04:23:30 |

| 126 forum posts | |

| Joseph Noci 1 | 28/01/2021 06:05:52 |

| 1323 forum posts 1431 photos | Nice work Sam. I have been searching for a small, low power ( sub 1Nm) 'zero' backlash gearbox and have been looking into these types of reduction boxes, as well as the cycloid reducers. The latter seem to be easier to machine but not so easy to achieve a few arc-minutes backlash! I built a 3D printer using Polar co-ordinate arms and the interface between my steppers and the arm pivot is only 10:1 . The steppers have a 6400 microstep resolution, so I was hoping it would all work - Does not..Some arm positions result in perceptable print nozzle 'wobble' as the motor step is not small enough. So I need to reduce down another 10:1 or more, and the printer mechanical structure makes it difficult to add such a reduction - hence looking into a small inline strain wave reducer. The cost even for such small ones is not insignificant. Not sure a 'printed' version will be good enough for my application though. Certainly looks good and amazing what the 3D printer has achieved. The pics below just to show where the reducer would have to fit. Joe

Edited By Joseph Noci 1 on 28/01/2021 06:06:59 |

| sam sokolik | 20/02/2021 04:40:40 |

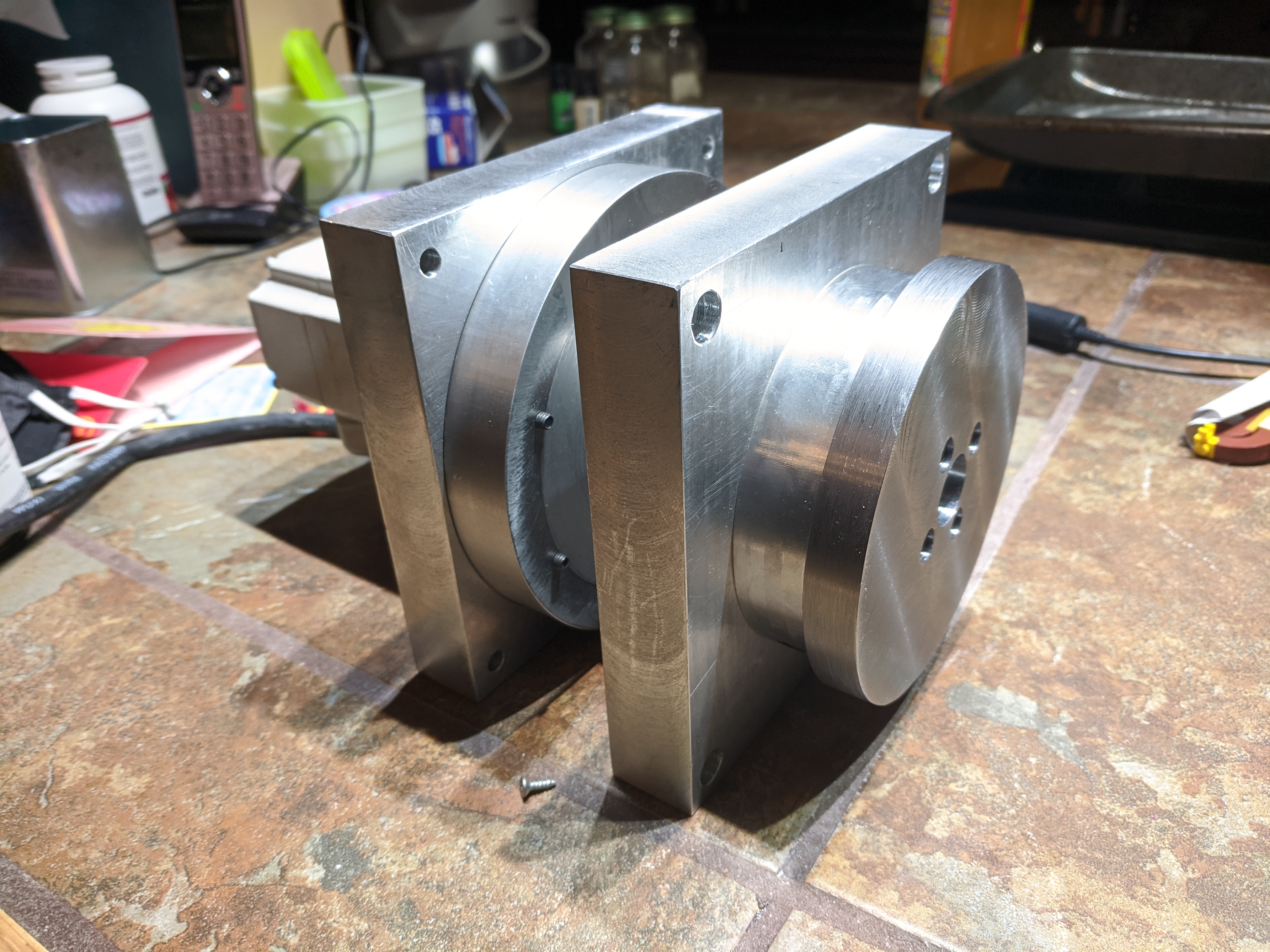

| 126 forum posts | started an actual 4th axis........ |

| sam sokolik | 23/02/2021 05:23:10 |

| 126 forum posts | and another update... |

| Michael Horner | 23/02/2021 07:19:09 |

| 229 forum posts 63 photos | Interesting stuff Sam. Is this something you are going to use? If nothing else it made me look it up on Youtube. Cheers Michael. |

| sam sokolik | 10/03/2021 04:19:34 |

| 126 forum posts | I plan on using at a lightweight 4th axis.. For either the turco or my 440 sized machine. |

| Neil Lickfold | 10/03/2021 06:06:37 |

| 1025 forum posts 204 photos | Thanks for sharing a great project. |

| Nigel Graham 2 | 10/03/2021 10:03:18 |

| 3293 forum posts 112 photos | Harmonic Drives... Not sure if it suits what you have in mind, but a contribution on What I Did Today, yesterday reminded me that a Scotch Crank with the crank as the driving rather then driven part, gives a harmonic reciprocating drive. (A regular crank or eccentric drive does not, due to the connecting-rod's obliquity, and the distortion increases with the shortening of the rod.) My recollection of this was very roundabout, as the post there was about a steam-engine. It had reminded me of reading of a Scotch-crank mechanism for calibrating small hydrophones at very low frequency (typically < 10, and indeed < 1, Hz). The hydrostatic head difference given by the vertical stroke immersing the transducer at a sinusoidally-oscillating depth change of only 100mm, is 1000Pa; equivalent to 60dB sound pressure-level in the 1Pa based scale used for measuring sound in water. |

| sam sokolik | 11/03/2021 23:26:33 |

| 126 forum posts | roughed out the back of the face plate....

|

| sam sokolik | 14/03/2021 03:13:19 |

| 126 forum posts | face plate mounted... Need to drill and tap a bunch of holes.. Getting there... |

| sam sokolik | 15/03/2021 04:17:12 |

| 126 forum posts | another painful update |

| sam sokolik | 08/04/2021 15:51:50 |

| 126 forum posts | more goofing around... |

| Michael Gilligan | 08/04/2021 17:08:09 |

23121 forum posts 1360 photos | That’s nice !! MichaelG. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in