Ideal Rotary Table size

| Keith Charters | 29/09/2020 10:59:44 |

| 5 forum posts 1 photos | Hi, I have recently bought a Sieg SX2.7 bench top milling machine and I am looking at buying a suitable Rotary Table. The table size is 140mm x 595mm. The options I have are a 4" or 5". Can anyone advise which would be better suited to this Sieg machine? My instinct is to go for the 5" but I don't know if that would be too big. All advice very welcome. Keith. |

| Mike Poole | 29/09/2020 11:16:14 |

3676 forum posts 82 photos | The two factors to play off against each other are the size of job you may work on and whether the RT will be awkward to use on the machine, any loss of axis travel or daylight may be annoying but can often be worked around. Mounting a large job on a small table might be even more difficult, of course the job will always come along that is too big no matter what size RT you have. I would go for the 5 inch as overall I think it would make life a bit easier, remember you need to hold the job on the table somehow and the larger table leaves more room for clamping. Mike |

| Emgee | 29/09/2020 11:18:58 |

| 2610 forum posts 312 photos | Hi Keith I believe the size depends on the dimensions of the work to be fixed to the table, if you intend to be making items larger than 4" then a 5" table will be needed to attach fixings. Another consideration is the height to the table in a horizontal mode, too high may restrict the spindle to table dimension so preventing work on some larger pieces of work, also even less workspace when a chuck is fitted on the table. Emgee |

| JasonB | 29/09/2020 11:50:54 |

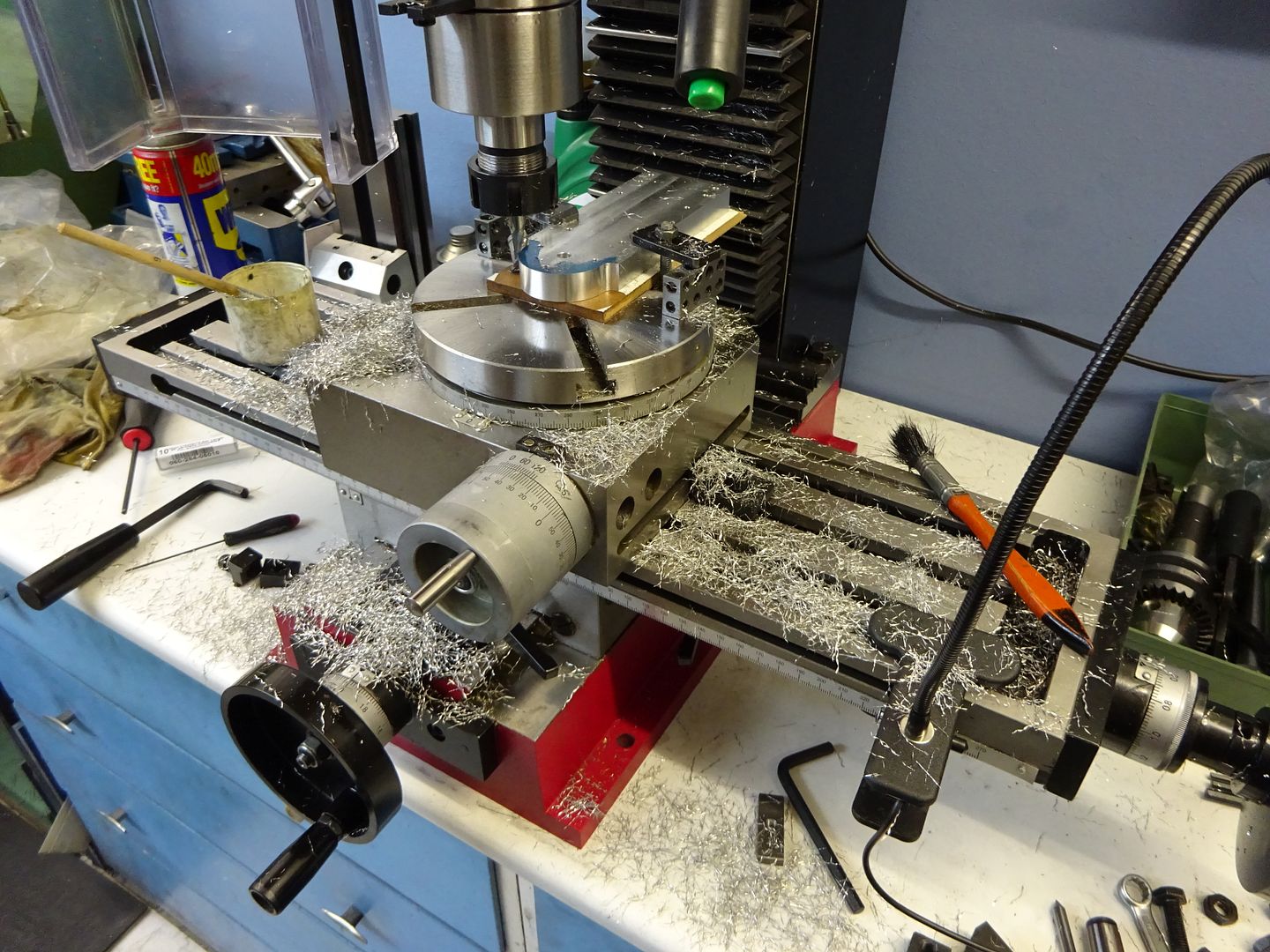

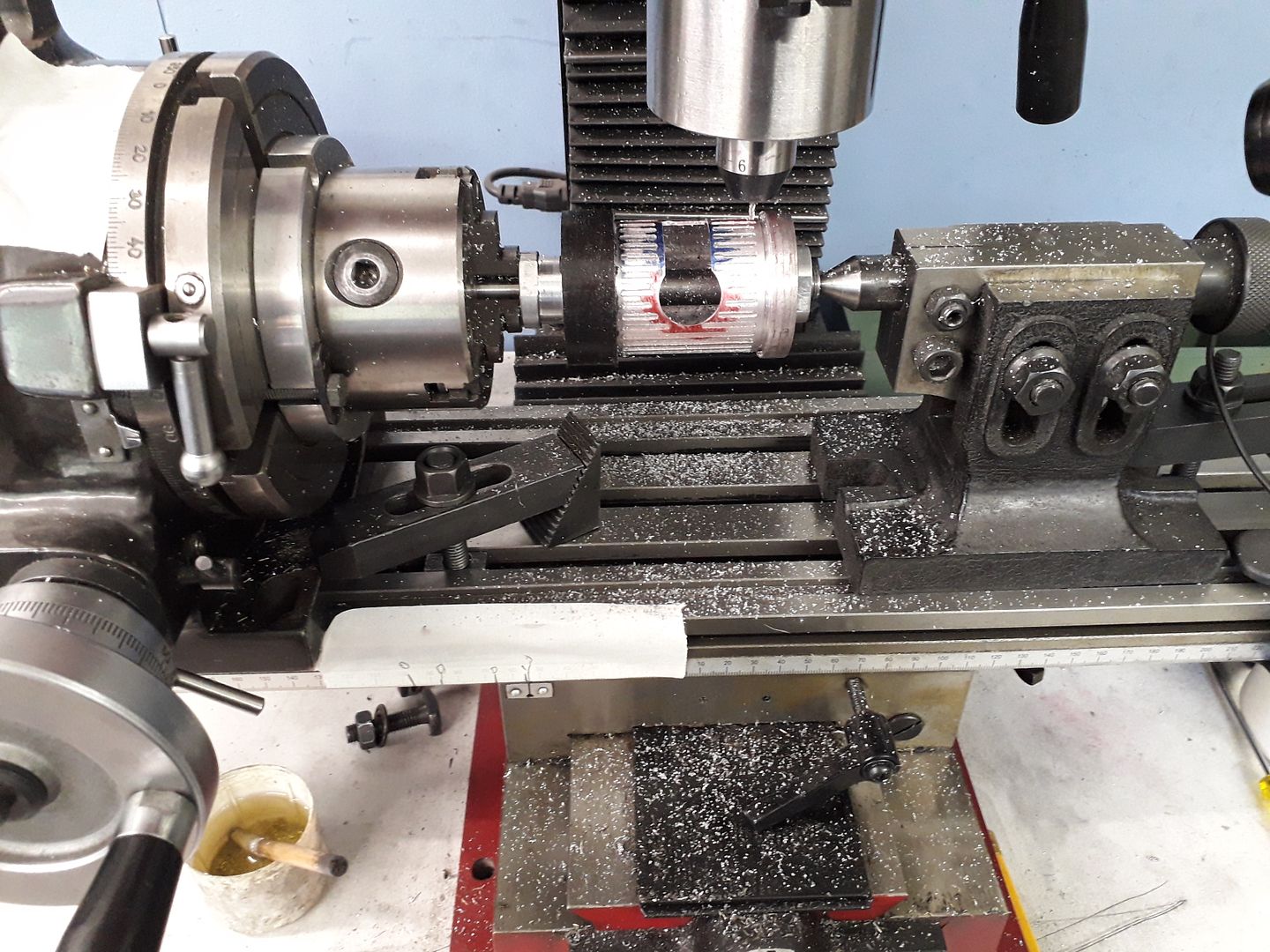

25215 forum posts 3105 photos 1 articles | I've used a 150mm one on the SX2.7 quite happily, the only time you may run into issues is if it is mounted horizontally with a large 3 or 4 jaw chuck on it and you are using a drill chuck and largish drill bit. Not had any problem milling items mounred directly to the table or in a 3-jaw.

Edited By JasonB on 29/09/2020 11:51:05 |

| not done it yet | 29/09/2020 12:28:14 |

| 7517 forum posts 20 photos | My milling machine tables are, according to the literature, 610 x 127mm and 530 x 139mm. I use 150mm RTs on either. Could have done with a larger one, if anything, for the Centec. A smaller one might have been preferable for the Raglan, but I get by. Other factors apply, rather than the table dimensions. Rarely(?) is anything ‘ideal’ - often not more than the job it was initially purchased for. It is usually a compromise of some sort. Edited By not done it yet on 29/09/2020 12:31:28 |

| Kevin Hodgkins | 29/09/2020 12:54:39 |

| 5 forum posts | I have a Soba HV6, on my SX2.7 it's fine using it horizontally, but vertically the mounting slots are too wide apart for the table t-slots. I've not needed to use it vertically yet, but I'm sure a clamping arrangement can be devised. |

| not done it yet | 29/09/2020 13:09:22 |

| 7517 forum posts 20 photos | Posted by Kevin Hodgkins on 29/09/2020 12:54:39:

I have a Soba HV6, on my SX2.7 it's fine using it horizontally, but vertically the mounting slots are too wide apart for the table t-slots. I've not needed to use it vertically yet, but I'm sure a clamping arrangement can be devised. Same here. My Vertex are the same. I have made a mounting plate for one of them, for one of the mills. |

| old mart | 29/09/2020 13:28:54 |

| 4655 forum posts 304 photos | I bought a 6" Soba RT which has horizontal and vertical with four tee slots. The vertical position needs clamping down on the mill drill, but the Tom Senior slots are just right. In the vertical position, I was concerned with its stability, and have drilled and tapped a pair of 8mm in the base to bolt on a small angle plate which can be clamped to the mill bed. I would go for the largest that you think will fit your machine, 5 or 6 inch diameter. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in