Carbide Inserts and Holder Recommendation

Carbide inserts for fly cutter

| Charles Oster | 20/09/2018 02:22:55 |

| 7 forum posts | Getting a new Precision Matthews PM-30MV mill next month. New mill, new tools, bigger projects. Just got a Sierra American 2-1/2" flycutter. Takes a 1/2" square tool bit. Have 4" & 6" bits on the way and lots of drawings on grinding the end. I would like to in the near future to try carbide inserts. Problem is that my head swims when I try to figure out what I need. If I grind an end wrong, I just touch it up. That gets expensive buying inserts. Can somebody give me some suggestions on make, model, holder, angles & + or - rakes that would be a good starting point? Especially something that will translate to America. Materials will be 1018 and 12L14 steel, 6061 aluminum and brass. Thank You!! I will appreciate any help I can get |

| JasonB | 20/09/2018 07:07:42 |

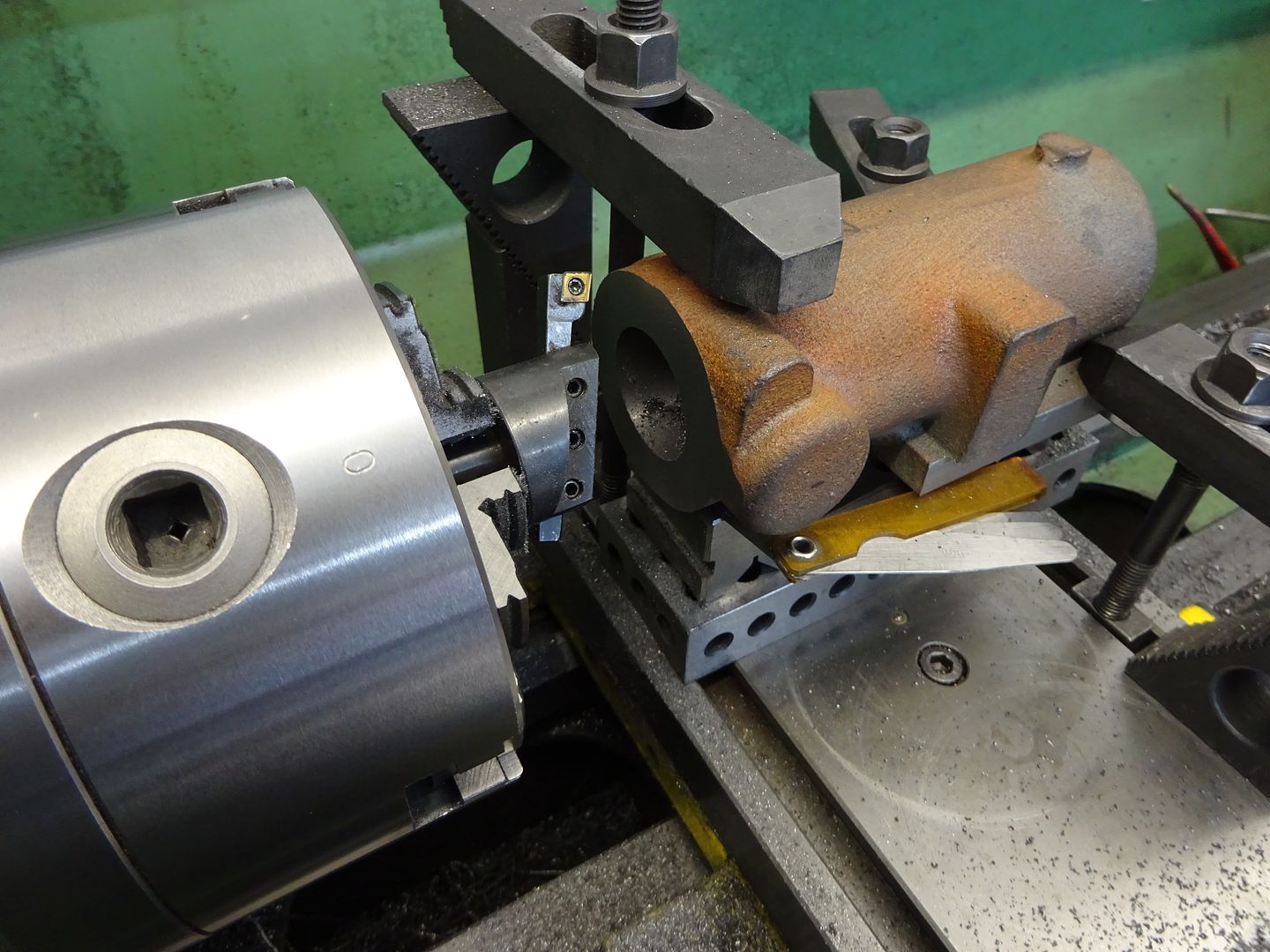

25215 forum posts 3105 photos 1 articles | You are probably better off getting a 50-63mm face cutter that using a single insert holder in your flycutter if you want to be using carbide. You will be able to feed at around 4 times the rate you would with a single cutting edge which also means smoother running for the machine and it's gears plus it will be balanced unlike a flycutter that can easily start to shake the machine about when you get upto the sort of speeds carbide inserts can mill at. Look for a facemill that takes APMT inserts as they are quite common and available in many specs to suit your materials, Watch out for the really cheap ones they can have issues! You will want one type for Ali and brass and another for the steels to get the best out of it, same would apply if using a single tool. If you do go down the single tool route then a left hand lathe tool works which takes the CC** type inserts and some people use the ones that take the round RC** ones, sorry don't know the US code numbers for these. This is a L/H turning tool in a flycutter

Edited By JasonB on 20/09/2018 07:36:22 |

| ChrisB | 20/09/2018 09:15:17 |

| 671 forum posts 212 photos | I made a Suburban flycutter clone which takes TNMG inserts like the original, I have experemented a bit with different insert corner radius TNMG1604 08, 12 and 16. Found the 16 radius leaves the best finish. The good thing about these inserts is they have six usable corners, apart from that, having neutral relief angle makes them more suitable for interrupted cutting - flycutting involves a lot of it. I'm using it on a WM18 which is similar to your PM-30MV. |

| mechman48 | 20/09/2018 10:45:38 |

2947 forum posts 468 photos | …'You are probably better off getting a 50-63mm face cutter that using a single insert holder in your fly cutter if you want to be using carbide. You will be able to feed at around 4 times the rate you would with a single cutting edge which also means smoother running for the machine and it's gears plus it will be balanced unlike a fly cutter that can easily start to shake the machine about when you get up to the sort of speeds carbide inserts can mill at'... |

| ChrisB | 20/09/2018 11:22:34 |

| 671 forum posts 212 photos | To add to my post above, I also prefer the face mill for the above mentioned reasons. But where a uniform surface finish is required and the face mill does not reach, the fly cutter comes in handy |

| Neil Lickfold | 20/09/2018 13:07:14 |

| 1025 forum posts 204 photos | There are some modern face mills that take a negative position insert, with a positive cutting geometry. The ones with the un even spacing are just awesome. These newer ones, have the 4 sided inserts, so will make a 45 deg approach, and the inserts have 8 cutting edges. They are quiet as well. Then there is the ones that side cut. The newer versions of these are both un even spaced, with a helical outside geometry , allowing for side cutting or going down a wall. These normally only have 2 cutting edges per insert. Kennametal make a great series and so does Mitsubishi, and Iscar. All 3 brands are available in the USA. Sadly the inserts are sold in boxes of 10, that will last a long time. The milling inserts are very well suited for interupted cutting. You can make a holder to take either of the inserts from the insert milling cutters. A common theme, is to make a holder that uses the un used edges from the vertical insert cutter that uses on 2 edges. Turned 90 deg, it can be used as a fly cutter on the edge that is no longer used. They used to make a face mill that used these inserts that way. Not sure if they still do or not. |

| JasonB | 20/09/2018 13:21:13 |

25215 forum posts 3105 photos 1 articles | I've just been sent a Video of the latest offering from Sieg spinning a face cutter at just shy of 5000rpm and 1mm DOC about 30mm wide in a non freecutting stainless under powerfeed. Great finish and a free fireworks display to boot that Andrew would be proud of. If you want to be using Carbide on a regular basis on the benchtop mills then this is the best way to make use of it rather than a lathe tool in a flycutter. |

| John Baron | 20/09/2018 14:57:31 |

520 forum posts 194 photos | Hi Guys, Lack of balance and vibration are just two of the issues with fly cutters. These are my fly cutter tools ! This one is on a 20 mm shaft and is made from a 20 mm thick steel disc three inches in diameter. The tool bit is basically any old bit of broken HSS. The piece that you see in the disc is a bit of 6 mm HSS, square lathe tool ground as required. It is simply secured by a single hex grub screw. This picture shows using a fly cutter to machine the fork of a bearing holder to a given thickness. The tool was simply turned over to cut the other leg and the mill run the other way. The large body mass has a flywheel effect and reduces vibration due to any out of balance.

Edited By John Baron on 20/09/2018 15:01:15 |

| David Taylor | 21/09/2018 01:08:01 |

144 forum posts 39 photos | I have a Tormach superfly that uses carbide inserts. I used it recently on cast iron with the inserts recommended for aluminium and it gave the best finish I've ever achieved at a speed easily within the capability of a manual mill. I'm planning on using it on my RF-45 clone in future. It has a 19mm shank. I'm sure there are clones of this cutter if you don't want to pay the Tormach price. |

| Charles Oster | 21/09/2018 16:07:59 |

| 7 forum posts | Thank You All!! I'm getting what I was looking for. I'm trying to do the setup shown in the lathe. I'm buying a Precision Matthews VF-1228 Lathe next year. If the tariffs don't bankrupt me! It has AXA tools that should fit, so I ordered them 6 months early. I was able to identify the TNMG inserts and ordered a couple of the -12. Can't ID the -16. Haven't found a 1/2" square tool holder, so I guess I will make one. Saw the big round one on Youtube. Looked interesting and the guy swears by it. I will make a couple when I get the lathe. The reason I bought the fly instead of the face mill was money. I used the extra savings to buy a 12" disk sander. Maybe in the future. Right now I need to clean up 5" wide stock and this fly should do it even with HSS tools. Looked at the Tormach in person. Fantastic! The machine shop at work just got one. But than I would want to buy a real Bridgeport. Anybody got some information on making a tool holder that uses the unused edges on the inserts from Neil above? Again Thanks!!!!! |

| ChrisB | 21/09/2018 23:17:54 |

| 671 forum posts 212 photos | A facemill from banggood does not cost much, I bought this 50mm **LINK** one for 36$ On the other hand if you want a flycutter which uses TNMG inserts you can have a look at Suburban tooling **LINK** but they are expensive. If you have a lathe and a mill you can easily replicate one, and size it to your requirements, if I had to redo mine I would make it smaller, it's a bit on the larger side and can cover a width of 10" - downside being it creates some vibration when sped up, but really and truly there's no need for high rpm at that swing. The TNMG inserts I have I bought from cutwel **LINK** they are of similar spec Suburban uses for their flycutter. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in