Single phase electric motor ?Faulty

Motor runs with regular "hunting" noise

| Paul Barter | 19/08/2018 20:58:23 |

| 112 forum posts 8 photos | Today I thought I'd try out a 1/4 HP, 240v single phase motor of senior years. New supply wiring after checking winding to earth seems ok. It is a cap start Hoover motor rated for continuous use and it is resilent mounted.The bearings seem fine when spun manually, bothe directions and the motor started fine and runs quietly, but, there's always a but, there is a regular groaning noise about once every second when the motor is under power. The centrifugal switch can be clearly heard disengaging on swich off and run down. Does anyone have any suggestions as to what may be causing this, I have been spoilt by using lovely smooth three phase motors, is the resilent mounting there to cope with the single banger design?Thanks in advance for any suggestions. regards Paul |

| Hopper | 20/08/2018 04:49:37 |

7881 forum posts 397 photos | Could be anything really. First step might be to strip it down and inspect for loose windings, swarf etc inside the working area. Clean it up. Fit new bearings and seals and give it another try. Bearings and seals are cheap so not worth putting the old ones back together. They could be the source of your noise. Or not. Only one way to find out. |

| SillyOldDuffer | 20/08/2018 10:43:39 |

| 10668 forum posts 2415 photos | Posted by Paul Barter on 19/08/2018 20:58:23:

... I have been spoilt by using lovely smooth three phase motors, is the resilent mounting there to cope with the single banger design? ... regards Paul Yes! Single phase motors are much more likely to vibrate than other types. As an AC motor that works on a domestic supply they're a compromise and more than adequate for many purposes. However, now that electronics can deliver affordable DC, 3-phase and Brushless power from a domestic supply, there are few good reasons for putting a single phase motor on a machine tool. It's not that single-phase motors are awful - they're just not as good as the alternatives, particularly where smoothness matters. Dave |

| larry phelan 1 | 20/08/2018 11:51:35 |

| 1346 forum posts 15 photos | Paul, There may be nothing wrong with your motor,I have one the same type/make,fitted with a sanding disc,operating for the past 25 years or more. It aint broke,so I,m not going to fix it . |

| Bazyle | 20/08/2018 13:31:18 |

6956 forum posts 229 photos | It does sound like an effect from the bearings. Have you tried applying an axial load (in line with spindle) to alter the bias on the bearings. |

| Paul Barter | 20/08/2018 13:34:40 |

| 112 forum posts 8 photos | Thank you all for your responses.I am reassured! I have feasted on three phase nectar, now for some single phase stodge, "You can eat it, but it tastes like cr*p" to quote Hogan. Thanks again Paul |

| Neil Wyatt | 20/08/2018 21:14:55 |

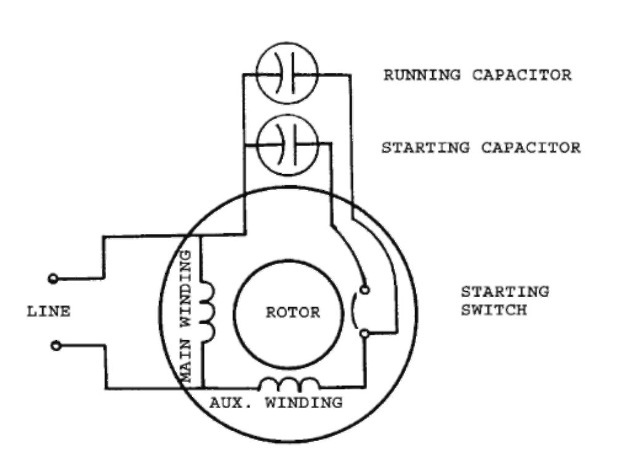

19226 forum posts 749 photos 86 articles | If it spins up, the switch clicks and it slows down that suggests it might be a dual capacitor arrangement and the run capacitor may be damaged. Neil

Edited By Neil Wyatt on 20/08/2018 21:15:53 |

| Paul Barter | 20/08/2018 21:33:32 |

| 112 forum posts 8 photos | Thanks Neil, for your clear diagram.This motor only has one cap for starting and noobvious run cap, the centrifugal switch is normally on and the start cap and start windings are isolated when the motor spins up.The switch can be heard closing when power is cut and the revs drop ready for the next start. However Bazyles comments made me think again and rolling the motor around its long axis whilst under power changed the vibration from zero to very bad. I hope this old lady has ball races and not oilite bushes! Although there apears to be no axial play even when powered up, the bearings are clearly sensitive to the orientation of the motor about its longitudinal axis, ergo excessive clearances I will be opening her up to see very soon. Thanks again Paul Edited By Paul Barter on 20/08/2018 21:34:58 |

| Paul Barter | 21/08/2018 11:43:00 |

| 112 forum posts 8 photos | Hello againI Have been inside and it has plain bearings, albeit with oil grooves and thrust washers but not much oil. There did not seem to be too much damage so a blow out with compressed air, smear of moly grease and a paper and wd40 polish on the spindle bearing surfaces and now it purrs. The weird noises must have been bearing related but not excessive clearances. This motor is probably almost as old as meand is now going to drive a picador linishing attacment, once I can get a small enough pulley. Thanks to all of you who were kind enough to suggest solutions regards Paul |

| Clive Foster | 21/08/2018 12:16:43 |

| 3630 forum posts 128 photos | Don't go too small on pulleys for your Picador. Mine came with an M section one a little smaller in overall diameter than the drums. Bought a similar size one for the motor but drive was never satisfactory. Lots of belt slip-stick and stall tendency if more than light pressure was used. Changed pulleys for largest I could get in. Want to say 3 1/2 inches OD but sold the finisher many years ago so can't be sure. Nowadays I use multi-groove so a small pulley would do fine. Made a new post for the table so I could lift it bit getting more belt clearance which helped. Think I also made longer bottom rails to use a readily available belt length too. Think getting Picador ones was hard in my neck of the woods. Even with the larger pulleys I had minor drive issues. Sorted those by turning things round and putting the drive pulley on the front drum rather than the more logical rear one. I imagine the longer belt put some shock absorbing into the drive as it could be seen jumping up and down in use. Cast iron bearings on mine had worn a bit oval so it got some T section oilite bushes with integrated thrust face, courtesy of a mystery box from friend Whistons Cat-a-log, and put proper flip top oilers on. Which meant new axles for the drums. Worth the effort as it was a freebie. Sold it after 15 or 20 years to get a modern Draper branded belt'n disk sander. Which was not an improvement! Interestingly that has a tooth belt drive to the drum. Clive. Edited By Clive Foster on 21/08/2018 12:18:51 Edited By Clive Foster on 21/08/2018 12:21:02 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in