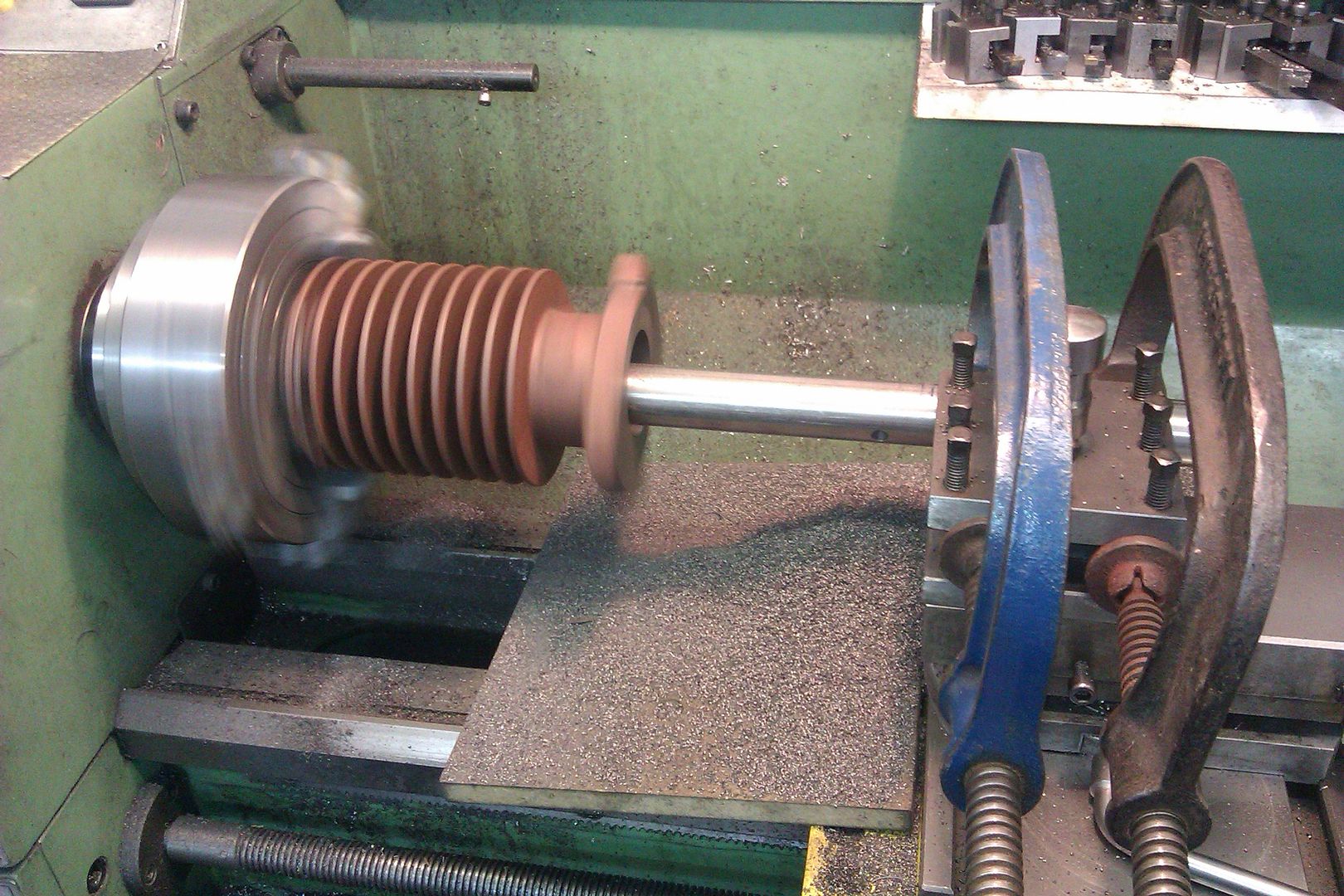

Boring in the lathe

tailstock boring head - tool position?

| Tim Stevens | 06/01/2018 18:20:30 |

1779 forum posts 1 photos | When boring using a conventional boring head in the tailstock, I usually position the adjuster dial upwards (for visibility and access), and the tool edge downwards. This seems to work OK. But is there any advantage in using the tool upwards in this set-up, or setting the boring bar with the adjuster horizontal, and the cutter towards, or away from, the adjuster dial? It seems to me that the sideways option can result in the forces on the tailstock moving it sideways where there is (inevitably) slack in the guides, whereas the up-&-down forces are better held firm by the tightening of the tailstock. But are the other factors at work? Regards, Tim |

| JasonB | 06/01/2018 18:29:11 |

25215 forum posts 3105 photos 1 articles | Can't say I have ever used the boring head in the tailstock for boring holes. I just use a boring bar in the toolpost which is more rigid and you have power feed for a better finish. |

| Oldiron | 06/01/2018 19:21:55 |

| 1193 forum posts 59 photos | I must agree with you JasonB. Its much easier to just dial in (or is that out) a couple more thou on the cross slide than messing with a couple of Allen keys to adjust a tail stock boring attachment. regards

|

| Joseph Noci 1 | 06/01/2018 19:46:28 |

| 1323 forum posts 1431 photos | I think you misunderstand Oldiron...Using a boring HEAD in the tailstock is very convenient. You adjust the cut by means of the micrometer adjustment on the head itself - no need to mess with Allen keys. Tim, I use that method often, especially when boring a number of inners to the same size - rough with boring bar close to size, and then finish with the tailstock/boring head - However, not when better than 0.01mm fit is required! Also, I set the cutter so that it is horizontal, same as would be with a boring bar in the toolpost. I find that the accuracy is better that way - tailstock is pulled down, which seems less movement on my lathe that sideways. However, good accuracy is hard to achieve as there will always be play in the barrel to body fit. Joe |

| JasonB | 06/01/2018 20:15:29 |

25215 forum posts 3105 photos 1 articles | Posted by Joseph Noci 1 on 06/01/2018 19:46:28:

I think you misunderstand Oldiron...Using a boring HEAD in the tailstock is very convenient. You adjust the cut by means of the micrometer adjustment on the head itself - no need to mess with Allen keys. Joseph, many boring heads have the micrometer screw turned by means of an allen key and the head is also locked and unlocked with an allen key to make these adjustments |

| Oldiron | 06/01/2018 20:32:49 |

| 1193 forum posts 59 photos | Joseph Noci 1 Both my metric and Imperial boring heads are adjusted using 2 Allen keys. one to adjust and the other to lock. Both have 2 different size keys. regards |

| Joseph Noci 1 | 07/01/2018 10:52:22 |

| 1323 forum posts 1431 photos | Ah, Well.....

Joe.. |

| fizzy | 07/01/2018 11:55:33 |

1860 forum posts 121 photos | I recently tried the boring head in tailstock method and found it highly unstable compared to using a normal boring bar in the toolpost - wont try it again.

|

| Tim Stevens | 07/01/2018 12:17:16 |

1779 forum posts 1 photos | My question was not asking about the wonderful advantages of other methods, but your experiences of this particular method in various positions. In case it helps, I have currently no suitable boring bar for the size of hole involved, so it's tailstock (with all its faults, no doubt) or nothing. I've tried nothing and it does not work for me. I won't try it again. cheers, Tim |

| JasonB | 07/01/2018 13:14:26 |

25215 forum posts 3105 photos 1 articles | Tim, if the cutter in your boring head fits the hole why can't that be held in the toolpost? |

| Tim Stevens | 07/01/2018 15:35:55 |

1779 forum posts 1 photos | JasonB, the answer is simple. My boring head, bought for my Myford, is inch, so the cutter is half-inch diameter, and I've pushed as hard as I can, but it won't go into my metric tool holder which is 12mm. I did think about making a half-inch adaptor, but that needs me to bore a hole which is smaller than my boring bar will fit. Deja vu, anyone? The sooner we get out of the EU and our metric tooling is all replaced by the government at EU expense with proper English sizes, the better. That was what the people voted for, after all. Cheers, Tim |

| JasonB | 07/01/2018 15:54:12 |

25215 forum posts 3105 photos 1 articles | You don't want to worry if the bar won't fit the toolpost, have you got any G cramps? That 12mm slot in the tool post will make a very good Vee block and fits all international standards

|

| Tim Stevens | 07/01/2018 16:04:17 |

1779 forum posts 1 photos | JasonB - the tool holder I have is designed for a boring bar, and has a 12mm hole through it. So, while I agree that I could remove the QCTP support and replace it with my old 4-square tool holder (like yours), and then use engineers clamps to hold the bar against the corners of the slot, I would still face the problem of height, and I was keen to get the job done before it went completely dark. Tim |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in