3D printing of gears

| vintagengineer | 14/12/2017 23:47:48 |

469 forum posts 6 photos | Is it possible to 3D print a stub tooth helical gear in a tough oil resistant plastic?

|

| Nick Hulme | 15/12/2017 00:22:34 |

| 750 forum posts 37 photos | Nylon 6 and Acetal are both A rated for Petroleum Oils resistance and can both be 3D Printed, it would be worth checking with Taulman as the the suitability of their Bridge Nylon for your project as it does print very easily and smoothly in comparison to other Nylon filaments, |

| Neil Wyatt | 15/12/2017 08:32:53 |

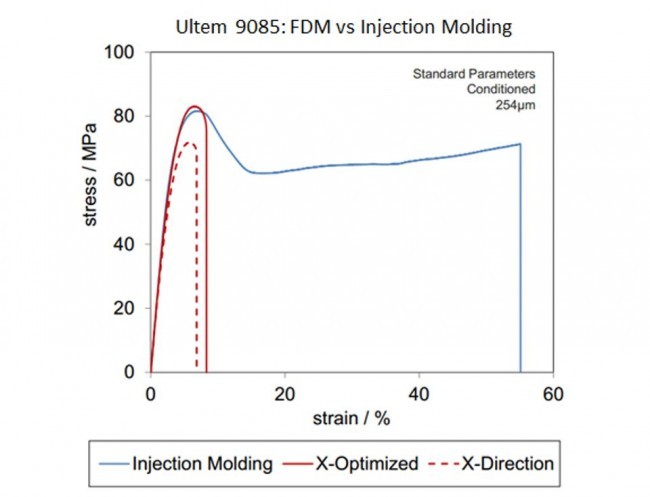

19226 forum posts 749 photos 86 articles | I've experimented with Taulman Nylon and it is quite a challenging material to get the settings right and good adhesion but the result was very tough. It should be strong enough if well printed this graph suggest a well oriented print will be almost as strong as injection moulding as long as it isn't distorted much. In practical terms, if overloaded the injection moulded part will fail by distorting but the printed one will break apart.

www.sculpteo.com/blog/2014/05/14/right-plastic-production-method-part-3/ Edited By Neil Wyatt on 15/12/2017 08:33:10 |

| vintagengineer | 15/12/2017 09:45:41 |

469 forum posts 6 photos | Thank you for replies. I now need to find someone to print a pair for me!

|

| JasonB | 15/12/2017 13:19:20 |

25215 forum posts 3105 photos 1 articles | That's after you find someone to draw the gears first. Suppose they could also be CNC cut with a 4th axis machine but you would still need the drawing. |

| Another JohnS | 15/12/2017 13:42:02 |

| 842 forum posts 56 photos | A few years ago a fellow club member drew out (via Matlab, if I recall correctly) a 43 tooth Module 1 involute gear, for using on one of my lathes that had a metric feedscrew and change gears. It was printed in Nylon, at his place of work (with permission), on a commercial 3D printer. It worked out really well. At the end of the run, other than a bit of grease/oil on it, you'd never have known that it had been used. We had expected it to be destroyed, but, nope! JohnS. |

| Roderick Jenkins | 15/12/2017 15:36:18 |

2376 forum posts 800 photos | A Google search for " DXF involute gear" throws up a number of different options for import into a cad program. HTH, Rod |

| Anna 1 | 15/12/2017 16:34:35 |

72 forum posts 3 photos | Hello vintage engineer. I know virtually nothing about 3D printing of nylon. I have however a small amount of experience with injection moulding of a range of plastics. Before moulding nylon it was necessary to blow/heat dry the nylon to remove the moisture content. Failure to do so would result in a steam blow back in the screw /barrel. how true it is I don't know but I have heard that barrels could explode. Whilst a 3D printer does not have a barrel as such, it would seem sense for the nylon to be dryed before printing to help with the integrity of the printed part. then put the finished part in a bucket of water for a few hours to regain its toughness before use. I hope this is relevant Anna |

| Neil Wyatt | 15/12/2017 17:15:12 |

19226 forum posts 749 photos 86 articles | Posted by Anna 1 on 15/12/2017 16:34:35: Whilst a 3D printer does not have a barrel as such, it would seem sense for the nylon to be dryed before printing to help with the integrity of the printed part. then put the finished part in a bucket of water for a few hours to regain its toughness before use. I hope this is relevant Very relevant, it is essential that nylon filament is dry to get decent prints. I had to dry my nylon filament in a low oven for a few hours. Neil |

| Nick Hulme | 15/12/2017 18:41:08 |

| 750 forum posts 37 photos | I dry Nylon filament at a measured filament material temperature of 80 Centigrade for four hours and once cooled to 30 Centigrade transfer it to sealed containers with moisture absorbent packs, filament is fed directly from the storage containers through PTFE tube to the extruder avoiding contact with atmospheric moisture. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in