Depth stop for Champion 16 mill/drill

| edintheclouds | 15/12/2015 14:00:48 |

| 50 forum posts 1 photos | Hi, I'm considering making a depth stop for my Champion 16 mill/drill. Just wondered if anyone has already produced one? It must make life a lot easier when drilling blind holes. Les |

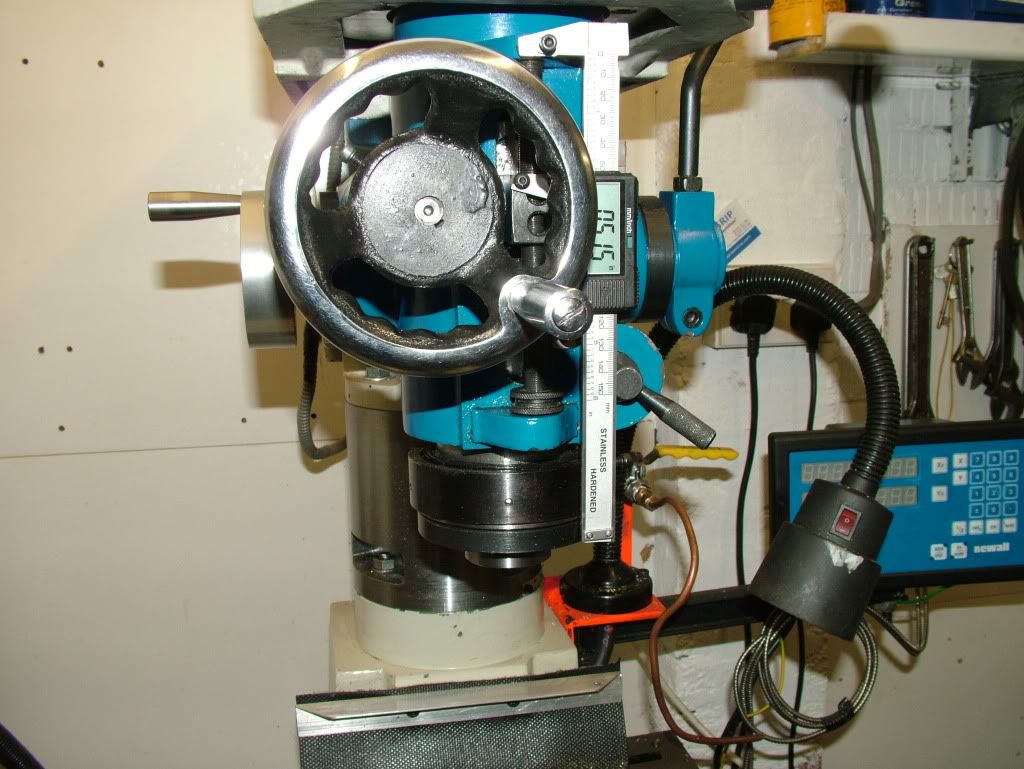

| Nobby | 15/12/2015 15:16:17 |

587 forum posts 113 photos | How about something like this Les Edited By Nobby on 15/12/2015 15:16:52 |

| Vic | 15/12/2015 17:36:39 |

| 3453 forum posts 23 photos | I put a digital scale on my mill. Fairly straightforward fitting. |

| edintheclouds | 16/12/2015 09:14:59 |

| 50 forum posts 1 photos | Thanks for the photo Nobby, I would be happy with threaded stud and adjusting nut at the moment. I will keep the clock and DRO in mind when making the bracket, thanks Vic.

Cheers |

| Clive Foster | 16/12/2015 11:54:37 |

| 3630 forum posts 128 photos | Threaded stud sounds a good way to go but in practice is over engineering things. Takes forever to wind the nuts up and down. My big Pollard 15 AY has a simple round rod with a split clamp on it. Loosen clamp, slide into position and lock. Much faster and easier. There is a deep engraved scale on the rod to hep setting but its not that easy to read. My experience is that scales on depth stop rods never get beyond sort of OK. The Chester Lux type mill I used to have came with a monumentally frustrating depth stop consisting of a threaded rod loosely fitted into a collar on the quill with a knurled rod underneath to turn the screw driving a Tee shaped nut up and down in a slot in the front panel of the head. Pointer on the nut indicated positions via a rather nice scale on the panel. The various clearances involved made setting very much a miss-miss-miss- hit or curse affair. I replaced the screw with a fixed rod, drilled the Tee nut out for a wing headed bolt so it could slide up and down easily. Put a copper slug under the bolt to prevent damage to the rod. Worked a treat. I imagine something similar could easily be arranged by fitting a plate to carry a laser printed scale. The need it now super fast scale bodge is to clamp an ordinary ruler or even pocket tape measure in position. Heard of one 3 cable ties and tape measure set-up that was used for several years in "I'll do a proper job when I get time" mode. Clive. PS poxy auto spell check! Edited By Clive Foster on 16/12/2015 11:55:13 Edited By Clive Foster on 16/12/2015 11:55:39 Edited By Clive Foster on 16/12/2015 11:56:17 Edited By Clive Foster on 16/12/2015 11:57:16 |

| edintheclouds | 16/12/2015 12:29:44 |

| 50 forum posts 1 photos | Thanks Clive, I like the idea of a rod and sliding clamp, I know what mean about winding the nuts up and down. Cheers Les |

| Vic | 16/12/2015 15:04:46 |

| 3453 forum posts 23 photos | Here's a £10 idea from one of the forums.

|

| edintheclouds | 16/12/2015 15:28:11 |

| 50 forum posts 1 photos | Thanks Vic that looks a great idea. Cheers Les |

| Vic | 16/12/2015 18:51:30 |

| 3453 forum posts 23 photos | Be warned Les, some of those scales can be tough to drill! I think I used a small glass drill to make a hole in one of them once. |

| Clive Foster | 16/12/2015 20:05:49 |

| 3630 forum posts 128 photos | This is the split clamp on a rod style stop on the Fredr'ck Pollard 15 AY pillar drill. Scale not as clear as it could be. Clamp bolt currently a socket head cap screw which I've been meaning to replace with something finger friendly for best part of a decade. Don't use it much and don't have anything suitable in the box so .. The modified calliper and similar vertical scale devices make nice quill depth scales but every fitment I've seen always gets in the way of things to some extent. The popular Quillstar and clone fitments on Bridgeport heads cover the stop adjustment nuts so you pretty much have to choose between a really nice depth scale and (relatively) easy depth / power feed stop setting. Not that the standard Bridgeport setting process is particularly quick and easy at the best of times. Way back I put a BW Electronics pull wire system on my quill. Had to run the wire over a pully 'cos it came out the wrong side but its still the neatest and least intrusive system I've seen. Often wondered if there is a way to do a similar out of the way cable style operation on one of the cheap scales. Or maybe its possible to rip the electronics and thimble rotation sensor out of a digital micrometer and drive it via a spring tensioned endless cord system as used on the big old valve radios like mum & dad, or granny & granddad, used to have. Clive. Edited By Clive Foster on 16/12/2015 20:07:39 Edited By Clive Foster on 16/12/2015 20:09:05 |

| Vic | 16/12/2015 20:21:43 |

| 3453 forum posts 23 photos | That's very neat Clive, not seen anything like that before. |

| Gary Wooding | 17/12/2015 12:11:06 |

| 1074 forum posts 290 photos | I faced a similar dilemma when I added a depth stop to my Centec VH. I used a threaded rod with a pair of Tilt-Nuts for the actual stop. The tilt-nuts have the useful property that, when tilted they "unlock" from the threaded rod and can be moved up and down easily; they re-engage with it when un-tilted. In use, the lower one lowered to the stop block, which orients it to engage the thread. The top one is the lowered until it meets the lower one, which orients it to engage the thread when they can be locked together. |

| Vic | 17/12/2015 13:55:09 |

| 3453 forum posts 23 photos | Thanks for posting Gary. For anyone else who's never heard of Tilt Nuts here's some more information. |

| edintheclouds | 17/12/2015 13:55:13 |

| 50 forum posts 1 photos | Thanks Gary, I've an idea in mind which would need a clamp on the quill shaft as in the photos, using a plain vertical rod and a sliding clamp to adjust the depth. I would need to arc weld a bracket on the casting for the clamp to stop on. This will take me a long time to produce anything worth showing. Thank you to everyone for your help and advice.

Les

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in