How much of a morse taper needs to be in ( or "How can I stick an oversized taper in a tiny spindl")

| Rainbows | 20/11/2015 23:09:54 |

| 658 forum posts 236 photos | So one has a tiny lathe where the spindle is 1/2" and the thread is 1/2" BSW. Originally it used a MT0 but anything involving MT0 is rare so I was considering putting it to a MT1 socket.

However the whole 1/2" BSW thing means that the taper sticks out 20mm from its usual position. Would this cause problems with the grip of the taper?

I would like to keep the 1/2" BSW because I quite like this little Burnerd chuck I have. In theory I could obtain two spindles but that might be inconvenient. If anyone has an idea for getting a MT1 and 1/2BSW thread to coexist please mention it if the taper can't work on my current plan. Edited By Rainbows on 20/11/2015 23:17:07 |

| Hopper | 21/11/2015 02:44:32 |

7881 forum posts 397 photos | You may be able to get an MT1 reamer and open up the tapered hole a bit more? You may be able to cut down an MT1 taper to fit and it will still grip. Some of the micro lathes (eg, Optimum) use a cut down Morse taper of about half the usual length. It depends on what you want to grip. A dead centre would grip ok. A boring head, maybe not so much. Of course, you could look at drilling and tapping a thread into the end of the morse taper to be inserted and then use a length of threaded bar through the spindle (if it has a through hole?) like a milling machine does, iwth a nut and flat washer on the end.. |

| David Clark 1 | 21/11/2015 09:17:51 |

3357 forum posts 112 photos 10 articles | You used to be able to get Morse taper 0 from EBay. Probably still available. |

| Neil Wyatt | 21/11/2015 12:20:03 |

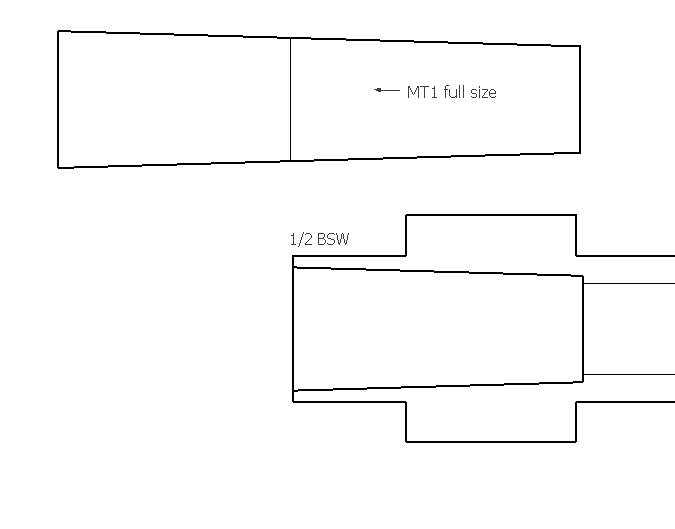

19226 forum posts 749 photos 86 articles | I put an Mt0 in my 1/2" adept spindle, and I think that is pushing it. Once you have allowed for the nose thread you have less than 0.4" to play with, so even with an MT0 the wall thickness under the thread is pretty small, MT1 is a non-starter. Pic below shows original 3/8" spindle compared to MT0 with MT1 in front, bottom shows the wall thickness with an MT0 taper in a 1/2" BSW nose |

| Rainbows | 21/11/2015 13:28:22 |

| 658 forum posts 236 photos | I worked out that if I had a 40mm long fat nose on the end it would allow me to have a MT1 then I could put a 1/2" BSW ended MT1 arbor on the end but then I lose the use of the lathe gap and I quite like my faceplates. That and it takes almost a 1/3 of my capacity away since its 6" between centres. |

| Neil Wyatt | 21/11/2015 13:40:18 |

19226 forum posts 749 photos 86 articles | Fair enough, What do you want to use on the lathe that needs an MT1 centre? Dead centres are easy enough to get. Neil |

| Rainbows | 21/11/2015 14:10:10 |

| 658 forum posts 236 photos | Reason 1 is because J Stevenson who is kindly making me a spindle doesn't have any MT0 reamers. Reason 2 is because you can get ER collet chucks with 1MT shanks which would be more convenient than making a backplate style chuck. |

| Brian G | 21/11/2015 14:47:34 |

| 912 forum posts 40 photos | I have a replacement tailstock on my Unimat SL that has an integrated ER11 collet holder and a Unimat 3 14x1 thread for the collet nut. Perhaps it might be worth considering doing the something similar for your new spindle, but making a collet closer with a 1/2" BSW thread? That way you could hold 0.5 to 7mm (or 8mm with oversize collets) within the spindle and still use your threaded tooling. Brian |

| Ajohnw | 21/11/2015 15:06:19 |

| 3631 forum posts 160 photos | Posted by Neil Wyatt on 21/11/2015 12:20:03:

Once you have allowed for the nose thread you have less than 0.4" to play with, so even with an MT0 the wall thickness under the thread is pretty small, MT1 is a non-starter. Neil

I agree with Neil. No chance even with just part of an MT1 going in. There isn't enough meat there. About all you could put in the end is an ER8 collet taper and make a nut probably forgetting the self extract feature and tapping them out with a drift down the hole in the spindle. The spindle nose would probably take up to ER16 but the collet chuck would have to be made, both threads and ends cut in one setting and the collet cone taper added when it's mounted on the spindle.. As there is no register on the spindle nose the thread fit would need to be pretty precise. Really one setting is essential anyway.Threads do tend to self centre under load but it wouldn't be wise to allow too much clearance. The thread angles would need to match. Maybe screw cutting and just cleaning up with a tap and die using a tap that is actually on size and a split adjustable quality die.

If you do make one I would be inclined to use leaded free cutting mild steel. Things are less likely to bind together. Cast iron is better in that respect though. Best to buy the nut if you do this. John - Edited By John W1 on 21/11/2015 15:09:25 Edited By John W1 on 21/11/2015 15:13:56 |

| Neil Wyatt | 21/11/2015 19:21:14 |

19226 forum posts 749 photos 86 articles | Posted by Rainbows on 21/11/2015 14:10:10:

Reason 1 is because J Stevenson who is kindly making me a spindle doesn't have any MT0 reamers. I can drop an MT0 reamer in to John. A deposit will be required Once its working, hwy not make your own MT0 ER16 chuck? A nice wee project. Neil |

| Rainbows | 21/11/2015 20:45:58 |

| 658 forum posts 236 photos | Posted by Neil Wyatt on 21/11/2015 19:21:14:

Posted by Rainbows on 21/11/2015 14:10:10:

Reason 1 is because J Stevenson who is kindly making me a spindle doesn't have any MT0 reamers. I can drop an MT0 reamer in to John. A deposit will be required Once its working, hwy not make your own MT0 ER16 chuck? A nice wee project. Neil hmmm, never touched an ER collet before but hey finding out how those things get made would make some good reading. For extra challenge I need to think of a way to make it on this tiny lathe too.

Hohn had the idea of using a taper pin instead since he has access to said reamer. Considering 0MT parts other than deadcentres are in low supply I might just use taper pins. Easy to make dead centres from them by just turning the end to a point while in the lathe and as easy to make my own parts as it would be for a morse taper. |

| steve de24 | 21/11/2015 21:39:22 |

| 71 forum posts | Rainbows, if you google 'doubleboost er collet' you will find a series of youtube videos of a guy making an ER collet for his Boxford lathe, about 60 minutes in total. regards, Steve

|

| Bazyle | 21/11/2015 22:20:27 |

6956 forum posts 229 photos | Not sure what the lathe is but you could also consider 6mm watchmakers collets. While not as common as 8mm they and other 6mm fittings are around. |

| Rainbows | 22/11/2015 19:33:54 |

| 658 forum posts 236 photos | Posted by steve de24 on 21/11/2015 21:39:22:

Rainbows, if you google 'doubleboost er collet' you will find a series of youtube videos of a guy making an ER collet for his Boxford lathe, about 60 minutes in total. regards, Steve

That was a very usefull in the end, that guy does good videos. Here is my complaint of the day: the collet nuts use 22x1.5 threads on them. I can buy a chinese die for £5 or a chinese die that has been imported into britain before hand for £15 but either way what are the chances of ever needing a m22x1.5 thead except for this particular job? Unless I start mass producing these little collet chucks I might as well just snap the die in half after I have used it and grind it into lathe bits. I suppose that is the good thing about having a full compliment of screwcutting gears. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

At least it's bsw so there may be some old accurate stuff around. New modern taps tend to be oversize. Die's a bit mixed and holder usually bang on size rather than being a bit over so that the die can be opened up a bit.

At least it's bsw so there may be some old accurate stuff around. New modern taps tend to be oversize. Die's a bit mixed and holder usually bang on size rather than being a bit over so that the die can be opened up a bit.

Register

Register Log-in

Log-in