Cylinder Boring Techniques for Steam Engines

| Clive Hartland | 24/09/2012 07:46:10 |

2929 forum posts 41 photos | I agree with Jason on the bore, hone it out first and see what you get. Regarding the proximity of the steam port to the bore, I would not worry about it as honing will only take a small amount of metal away . In any case the steam passage is angled down towards the steam chest and it is only close to the bore at the recess and at no time will interfere with the piston. Clive |

| Will Robertson | 24/09/2012 22:14:53 |

162 forum posts 41 photos | Hi Clive and Jason, I'll do a diagram of the piston bearing in mind your advice so that we can check if it's right before i start machining it. When it comes to honing I know almost nothing. The closest I ever came was re-grinding valve seats using "coarse and fine" grinding paste as a child. People have mentioned using a piece of nylon or wood turned to sise and split with a screw in the middle and some grinding paste applied but I don't know where to buy the grinding paste or what grit to use. BRW do this product - the Flex-Hone which seems interesting - **LINK** (Thanks for the advice about browsing the BRW catalogue Clive!) I suppose I could try using some abrasive paper of the right grit moistened with paraffin and pushed against the lathe mounted cylinder bore using a hand-held piece of wood but I've a feeling this might give erratic results - not sure though. Will |

| Clive Hartland | 25/09/2012 07:58:52 |

2929 forum posts 41 photos | Turn a piece of wood so it just enters the bore, this being about 10cm long and make provision for holding it. The wood being something like a piece of broom handle or such, not pine. Then cut a slit almost down to the handle and make a very thin wdge and it can be advanced to expand the diameter slightly. Then try and get some 1000 grit, you only need a little and in fact you could use scouring powder/cream. keep it wet and spiral it up and down the bore until you are satisfied with the result. Clive |

| JasonB | 25/09/2012 08:21:44 |

25215 forum posts 3105 photos 1 articles | You may just be able to squeeze on of the brake cylinder hones down the bore, these are readily available on e-bay and have a stone that hones the surface, here is one in action on one of my engines, the smaller two stone one should just fit the S50 If using an iron ring I would leave the cylinder with this honed finish. What you and clive are talking about with the wood is lapping not honing, this will take a long time to remove the tooling marks, so start by honing and then finish by lapping. You can also make a lap from aluminium or copper, have a look at my Firefly build in the work in progress section to see it being done, work through 320, 600 and 1000g if you still find it. Again plenty of lapping powder upto 600g on e-bay, Veritas do small amounts for the woodworkers

|

| NJH | 25/09/2012 10:04:48 |

2314 forum posts 139 photos | Hi Will I bought a small hone from here - it worked well - but slowly! It is necessary to keep it well lubricated ( with honing oil) whilst it works and , as you may imagine, the potential to spray oil all around the workshop is considerable! In the best ME tradition I adapted a plastic fruit container to catch the oil and set it up carefully on my pillar drill. This allowed the slow speed and continuous movement in and out of the cylinder that is required. As I say it took quite a while but did produce a good finish.

Regards Norman |

| Will Robertson | 28/09/2012 11:39:01 |

162 forum posts 41 photos | Hi Clive, Jason and Norman, Sorry about the delay replying - I've been on holiday for a bit. Thank you very much. I hadn't understood the difference between honing and lapping. I can see that when the cylinder has been bored well only very light lapping would be needed but when it's in a real mess honing would be needed first. Thanks also for the advice to avoid pine (without this I'd probably have made a beeline for the nearest chunk of scrap pine...). For honing oil do I have to use special honing oil or can I get away with the ordinary cutting oil used for turning? PS - I think I recognise the plastic fruit container - I think I remember them doing very tasty peaches in syrup in an easily re-usable and recyclable container - a great favourite with my late mother - can't get that brand over here unfortunately. For my own engine, for the screws that tighten the packing glands on the main cylinder and the cylinder for the piston valves should I use a metric coarse or metric fine thread? (I've a feeling it should be metric fine but I'm not sure - I had no idea that metric fine existed until someone on here told me - all the metric taps, dies, nuts and bolts in the workshop where I learned were metric coarse so I never knew that there was anything else!) Will Edited By Will Robertson on 28/09/2012 11:57:01 |

| JasonB | 28/09/2012 13:12:03 |

25215 forum posts 3105 photos 1 articles | Parafin or Kerosene will be OK for honing the cast iron I find oils tend to clog the hone but Parafin flushes the fine particles away. Metric Fine would be a better match to the ME threads that Stuart suggest for the threaded glands.

J |

| Will Robertson | 28/09/2012 21:44:45 |

162 forum posts 41 photos | Hi Jason, Thanks - I'll try to get my paws on some Paraffin (would Diesel be OK as well? - I think it's similar to Paraffin and Kerosene but a bit lighter). I've got two projects on at the moment - the restoration of a cankered S50 bought on ebay and designing and building my own engine from scratch - the question about the thread was for my own engine not the S50 so matching Stuart suggestions isn't important. Will |

| JasonB | 29/09/2012 07:26:41 |

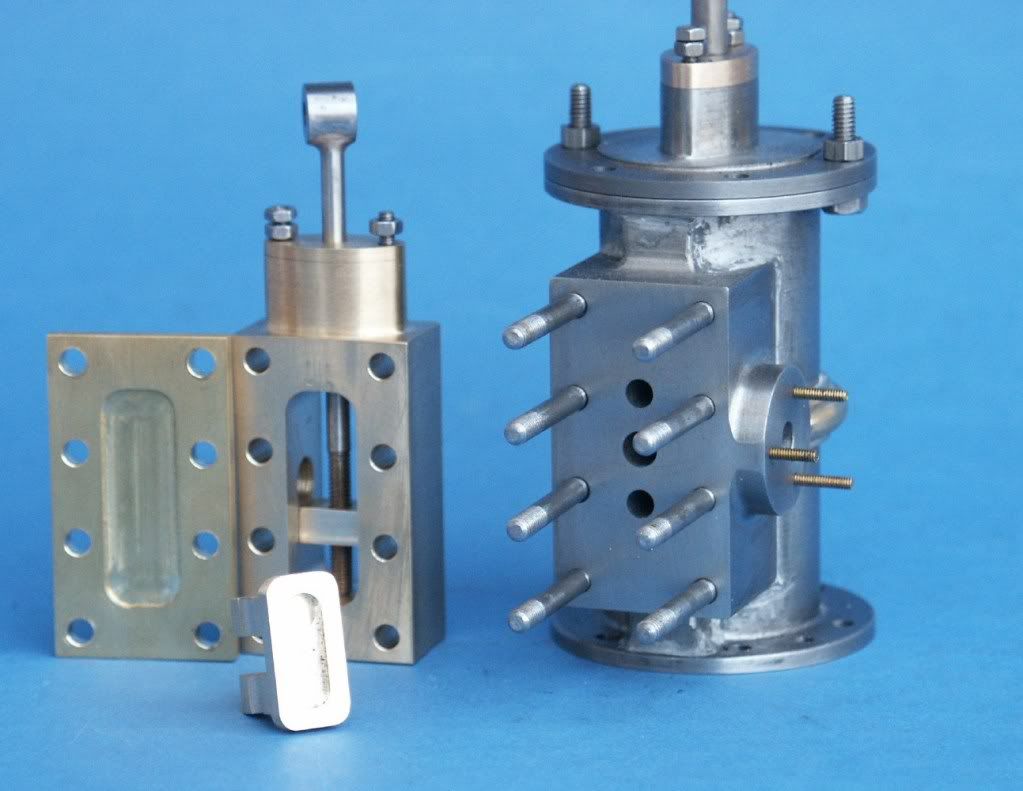

25215 forum posts 3105 photos 1 articles | Is your engine going to be larger that the S50? If so then rather than screw in glands I prefer ones that are held by studs & nuts which will allow you to use standard metric coarse threads, this is teh sort of thing.

J |

| Will Robertson | 29/09/2012 22:56:52 |

162 forum posts 41 photos | Hi Jason, My model will be larger than the S50 but probably not by much. I think the outer diameter of the cylinder will be 30mm and the diameter of the cylinder bore 20mm. Practically, I'm limited by the sise of the lathe. I'll definitely keep your suggestion of studs and nuts in mind - I'd like to think about building a larger engine in future - I think you're right that studs and nuts for the glands would definitely be better than screw-in glands (and more historically accurate). By the way - how did you machine the neat oval shape? I've heard of complicated way of doing this but often reckoned that there must be an easier way. Some progress on the honing: Before going to the expense of buying a honing tool I asked the garage next door if they had a brake cylinder honing tool - they've abandoned traditional honing tools in favour of the flex-hone type tools - I'll borrow one of these and give it a try. Will |

| JasonB | 30/09/2012 09:59:35 |

25215 forum posts 3105 photos 1 articles | At that size the stud & nut method will still be usable, although the ones in the picture are 3" and 2.5" dia cylinder covers they are from a doubled up design so that would give 38 & 32mm dia cylinder covers on the original model. I've also used them on smaller cylinders, the traction engien in my avitar is 5/8" (16mm) bore and the valve rod has an even smaller gland

The shaped gland in teh picture was just filed to shape but I often do the two large arcs with a boring and then just file around the stud holes using buttons or eye. Thats how these were done and the boss on the cylinder cover and valve chest machined at the same setting.

|

| Will Robertson | 01/10/2012 21:25:45 |

162 forum posts 41 photos | Hi Jason, Thank you for the advice - I think I'll definitely use your type of valve glands in a future engine - possibly a larger engine. For the engine I'm planning at the moment I'll maybe go for the screw-in type glands just because they should be simpler to machine (I'll use a set of taps rather than cutting threads). I could maybe also add them to this engine as a later modification but best to keep things simple initially (I've already made things fairly difficult as it is with the piston valves). Will Hi Michael, Thank you very much for your help. I've sent you my email address in a message. (I never put my email address on a web page because there are folk with horrible programs that search the internet for email addresses which they then sell in bulk to advertisers who want to bombard folk with unwanted emails.) Will |

| Will Robertson | 02/10/2012 20:40:07 |

162 forum posts 41 photos | Hi Michael, Thank you very much for recommending Greenly's - the 1973 edition of Greenly's I ordered came today - it's much better than any other book I've seen - it's great to see sound theoretical and practical understanding, good descriptions, close-up photos, precise descriptions of alloys used and even a few equations. Will |

| Will Robertson | 05/10/2012 21:50:15 |

162 forum posts 41 photos | An update of the restoration of the S50 (a la ebay): Very determined use of a flex-hone finally got the bore into a condition which I think will be good enough to work. Initially I took a slow, careful, light-touch approach but it became clear after half an hour that this was not enough. With the encouragement of the owner of the garage next door we tried more aggressive honing (higher speeds and a bigger flex-hone) and this finally smoothed out the worst of the gouges. I think if I ever had to repeat this restoration I would re-bore in the lathe - the gouges in the bore in this case were simply so deep and so bad that they couldn't be taken out easily by honing. (I've no idea how someone made such a mess of a bore in the first place.) Reading Greenly's has been very valuable. The drawback is that Greenly himself was an experienced machinist and so didn't provide many details of how to machine the engines he designed - does anyone know a book like Greenly's but giving information about how to machine components to the required tolerance? I'd like to read a bit more before finishing plans for my own engine. Edited By Will Robertson on 05/10/2012 21:51:23 |

| NJH | 05/10/2012 22:22:42 |

2314 forum posts 139 photos | Will I don't know about books on machining engines but for superb descriptions of many operations I find George Thomas hard to beat. Norman |

| Will Robertson | 06/10/2012 20:50:28 |

162 forum posts 41 photos | Hi all, Thinking over design for my engine I reckoned that I may have made a mistake. I planned a 5mm diameter piston valve for a 20mm diameter main cylinder (the valve a quarter of the diameter of the main cylinder). Greenly has his piston valves about half the diameter of the main cylinder so I think I should re-plan and make the piston valve 10mm not 5mm. What are people's thoughts on this? Hi Norman, Would "Model Engineers Workshop Manual" by George Thomas be a good book? Will

|

| Will Robertson | 08/10/2012 20:42:46 |

162 forum posts 41 photos | I'm getting closer to silver soldering the stock for the main cylinder to the part that will mate with the valve block. (To avoid the risk of distortion after machining I'll do this before the cylinder is machined.) The outer diameter of the cylinder is 30mm and so the amount of metal involved and its thermal mass will be fairly large. The stock I've got is brass so I think it should solder easily but I have to be careful not to overheat it (is there a risk I'll cause distortion or evaporation of some of the zinc?). I could reduce the amount of metal to be heated a little by drilling the cylinder bore first (but not doing the final boring). I've got silver solder that melts at 600 C and flux for silver solder (I don't know the exact details of the flux but it looks similar to simple borax flux). I'll hammer the silver solder into small flakes (many thanks again to the person who recommended this). The question is, will a propane/butane torch and a surround of firebricks be enough to get the temperature high enough? For this amount of metal I suspect not but I'm not sure. Back home in Scotland I'd reach for an ancient, large and much-beloved paraffin-fired blowtorch but I don't have one of these here and as far as I know it's not possible to buy them any more. I don't have access to MAPP gas. I could maybe persuade someone to let me use their oxy-acetylene welding gear but the nozzles will be for cutting and welding not heating and oxy-acetylene seems a bit decadent for some silver soldering. I can hopefully borrow an infra-red thermometer to keep an eye on the temperature. Any advice? |

| JasonB | 08/10/2012 20:58:40 |

25215 forum posts 3105 photos 1 articles | I would drill out some of the waste from the cylinder, this will reduce the mass that you need to get upto temperature. As you are working with large lumps of brass there should not be much risk of overheating, its more of a problem if soldering a small piece to a large one where the small piece will get upto heat long before the large part. For what you are doing I don't see the need to flatten the solder, if you want to place pallions then just snip a few bits off the rod, myself I prefer to feed in the rod when the work is upto temp. Its not so much the gas you are using but the BTU rating of the burner, a Propane torch with a 25mm nozzle should do the job, butane is not so good and although MAPP burns at a higher temp the torches are usually small Your flux will tell you the temperature, first it will bubble as the water is boiled off then it will look like dried spit and finally it will turn to a clear liquid, at that point you will be at the temp and the solder will flow J |

| NJH | 08/10/2012 23:15:04 |

2314 forum posts 139 photos | Hi Will You say " Would "Model Engineers Workshop Manual" by George Thomas be a good book? " Emphatically YES! This won't tell you much about cylinder boring technigues (directly) - most of the projects are workshop equipment - but the clarity of his writing and the way he can "hold your hand" through some seemingly complicated machining is quite brilliant. If you never make one of his designs you will still enjoy reading the book and I would be very surprised if you didn't learn from it. Put a copy on your Santa wish list! Norman Edited By NJH on 08/10/2012 23:15:55 |

| Will Robertson | 09/10/2012 11:57:33 |

162 forum posts 41 photos | Hi Jason, Thank you very much for your clear advice. I'd found forums where people have gone round and round in circles for ages discussing this but I think you're exactly right - for this kind of job it's the heat output more than the flame temperature that matters. Thank you also for your advice re. using probane rather than butane. I'll start trying to track down someone willing to lend me a 25mm propane blowtorch (may take some time!). The flux I've borrowed is a white crystaline powder (guessing possibly borax which melts at 740 c but that's just a guess) in a plastic tub with "silver solder flux" written on it in pen (in German) - it doesn't give me any other info. (I looked at buying flux but could only find it in expensive 0.5 kilo tubs.) Hi Norman, Thanks. I suspect that Santa may not be able to deliver via the narrow Swiss chimney here but I'll have a go at getting my paws on a copy of the the book by other means. Will |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in