Mini-Lathe Repair

| Neil Wyatt | 21/12/2018 10:32:12 |

19226 forum posts 749 photos 86 articles | Posted by Ron Laden on 21/12/2018 07:47:22: I was surprised at that as I thought a carbide at low revs would struggle. Don't say that, we need the old chestnuts for Christmas All depends of the geometry of the insert, most of the anti-carbide sentiment (I used to share) was passed on as received wisdom when the choice and availability of inserts for hobby use was much less. Neil |

| Andrew Johnston | 21/12/2018 10:55:03 |

7061 forum posts 719 photos | Posted by Ron Laden on 21/12/2018 07:47:22:

I was surprised at that as I thought a carbide at low revs would struggle. Ah yes, but the diameter was small. So the force available from a given torque would be adequate. If you tried to cut the same thread on a 120mm, say, diameter you might get a different result. Since the radius is bigger the force available will be lower for constant torque. Andrew |

| Ron Laden | 28/12/2018 09:19:41 |

2320 forum posts 452 photos | Had a bit more practice thread cutting this morning and out of interest I took a different approach, I didnt set the top slide at 30 degrees but set it square. I did all the cutting on the cross slide which seemed to work ok, pitch is 1.25 on 15mm steel bar. A couple of questions: I ran a fine file across the top of the thread (picture below) is it enough or is it normal to have more of a flat on the peaks..? Also I dont think the root of the thread looks quite right maybe I need to look at the tool..? |

| Andrew Johnston | 28/12/2018 09:31:13 |

7061 forum posts 719 photos | Looks good, but I agree the root/crest is a bit odd. I'd expect the crest to be flatter. What tool was used? A full form insert should automatically create the correct root and crest, provided you get the infeed depth correct. I always use the cross slide only for screwcutting, makes it easier to get the correct depth. Of course the acid test is does a mating part fit. Andrew |

| Ron Laden | 28/12/2018 09:40:45 |

2320 forum posts 452 photos | Thanks Andrew, the tool is a HSS 60 degree which came as part of a set I have, its a new tool and I havnt modified it at all. Ron |

| Paul Kemp | 28/12/2018 10:34:06 |

| 798 forum posts 27 photos | Ron, Profile on that one looks better than the first one (from the pictures). One way to check the tool geometry and get a rough and ready "full form" tool is to check out in a bolt of the same pitch (using it the same way as your screw cutting plate gauge). That will show you if the tip width / radius is somewhere near correct. I also only use the cross slide and don't bother setting over the top slide with the proviso that if the thread is tearing I add a couple of thou on the top slide to move the tool over a touch and bias the cut on one flank. Useful if the tip of the tool is too pointed as once you get to depth and the root is too narrow and then crest too wide you can kiss a bit from each flank, cleaning them up and getting a better finish and evening up the thread, if you get my drift? Good wheeze to get things right if the tip is too narrow and you are at full depth, using the top slide at half the thread angle doesn't give you that flexibility. Paul. |

| Ron Laden | 28/12/2018 10:41:53 |

2320 forum posts 452 photos | Thanks Paul for the tips, all good to know. Ron

|

| Ron Laden | 07/01/2019 08:43:04 |

2320 forum posts 452 photos | At long last I have received the aluminium bar to enable me to produce the motor and layshaft pulleys for the ribbed belt, the first lot got lost in Christmas post. I need to cut a 4mm x 2mm keyway in the layshaft pulley and was wondering if I could use the mill as a press. If I made up a 4mm broach from a piece of HSS and taking light cuts only would it work..? If need be I could use a 4mm cutter and cut 2mm deep and then square out the corners, depth of pulley is 15mm. It was just a thought. |

| JasonB | 07/01/2019 09:08:45 |

25215 forum posts 3105 photos 1 articles | Should work with light cuts of about 1 thou per pass and removing as much as possible first will help |

| Ron Laden | 07/01/2019 09:37:16 |

2320 forum posts 452 photos | Posted by JasonB on 07/01/2019 09:08:45:

Should work with light cuts of about 1 thou per pass and removing as much as possible first will help Thanks Jason, will go with a 4mm cutter first which shouldnt leave to much to remove. |

| Andrew Johnston | 07/01/2019 10:29:26 |

7061 forum posts 719 photos | Posted by Ron Laden on 07/01/2019 08:43:04:

..........was wondering if I could use the mill as a press. If I made up a 4mm broach from a piece of HSS and taking light cuts only would it work..? Some while back I used the Bridgeport quill to cut a 3/32" keyway with a broach - wouldn't do it again as I think I was pushing my luck. Andrew |

| JasonB | 07/01/2019 10:42:16 |

25215 forum posts 3105 photos 1 articles | What material were you cutting Andrew? I think Ron is also talking about using the quill like a slotter not to drive a commercial broach otherwise no way to use "light cuts" Can also be done on the lathe using the carrage and if done on the mill no reason you can't use a narrower tool and move the work to get the final 4mm width I while ago I posted this internal gear done using the X3 quill, a wider cut than a 4mm keyway. Or 4mm wide into 6082, no special tool just touch up the slanted end of a HSS tool blank

Edited By JasonB on 07/01/2019 10:53:53 |

| Andrew Johnston | 07/01/2019 10:53:43 |

7061 forum posts 719 photos | Ah, I was wrong, it was a 1/8" keyway. Material was steel, keyway was 1-3/4" long and I used a commercial broach. I didn't use my slotting head as I thought it would deflect given the small (1/2" ) bore and length. I've solved the problem for the future by acquiring a proper arbor press. Andrew Edited By Andrew Johnston on 07/01/2019 10:54:04 |

| Ron Laden | 07/01/2019 11:11:44 |

2320 forum posts 452 photos | I never thought of doing it on the lathe so thats another option, thanks for that Jason. The tool you used on the 6082 part is basically what I was thinking as I would only be taking very light cuts and thought a simple tool should do the job. |

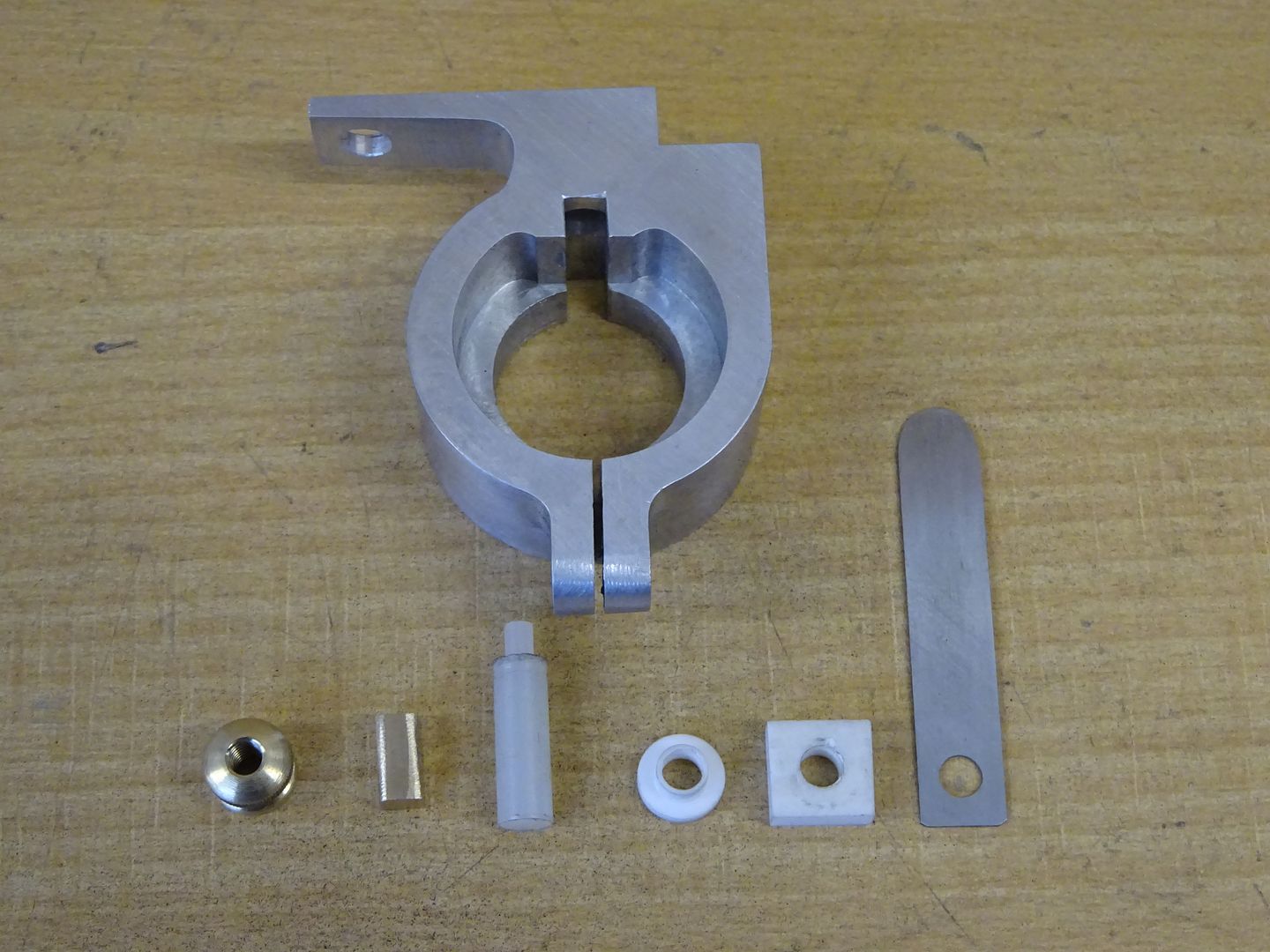

| Ron Laden | 14/01/2019 09:06:45 |

2320 forum posts 452 photos | I am about to make the Poly V belt motor and layshaft pulleys so I stripped the end of the lathe to get to the plastic originals to check dimensions. Good job I did as it through up one or two issues but nothing that cant be overcome. The motor pulley has a moulded key so in aluminium like the layshaft pulley it will need a keyway cutting plus a key. The end of the layshaft should be 10mm diameter but it measures 0.016 mm under size, also the key is a very loose fit in the keyway so needs replacing. The original plastic layshaft pulley is also very loose on the shaft and I wondered if it got "stretched" in the stall but I think it more a case of the loose key causing the wear. The Poly V belt is 10mm wide but I can only afford a pulley width of 12mm otherwise the pulley will contact other parts. That works out ok though as the centre of the belt outer ribs will be 2.5mm from each end of the pulley. Ron Edited By Ron Laden on 14/01/2019 09:28:57 |

| Ron Laden | 16/01/2019 08:05:54 |

2320 forum posts 452 photos | Machined the motor and layshaft pulleys which have worked out ok, hoping some tool steel arrives today so I can get the keyways cut. |

| JasonB | 16/01/2019 08:23:05 |

25215 forum posts 3105 photos 1 articles | Looking good so far. |

| Ron Laden | 17/01/2019 09:07:59 |

2320 forum posts 452 photos | Another first for me cutting a keyway, I used the mill and it worked a treat. I removed the bulk with a 4mm cutter and then used a piece of 4mm square tool steel for shaping as Jason suggested. Taking 1 thou cuts it was easy to do and quite quick. |

| Ron Laden | 17/01/2019 15:45:34 |

2320 forum posts 452 photos | Posted by Ron Laden on 17/01/2019 09:07:59:

Another first for me cutting a keyway, I used the mill and it worked a treat. I removed the bulk with a 4mm cutter and then used a piece of 4mm square tool steel for shaping as Jason suggested. Taking 1 thou cuts it was easy to do and quite quick. Jason, Have you used the HSS blanks for producing keyways without first removing the bulk of material with a cutter..? With the 12mm layshaft pulley I used a 4mm cutter which had enough flute length to cover the keyway length. The motor pulley however is 18mm and the keyway 3mm, I would need a long series cutter to machine out the bulk and even then I would need to cut from both sides to cover the 18mm. I can get a cutter to do that but was thinking is it worth trying without first removing material or even with 1 thou cuts is it going to be hard work cutting the full face. Ron |

| JasonB | 17/01/2019 16:07:08 |

25215 forum posts 3105 photos 1 articles | That one I showed a few posts above was done without pre cutting. All the steel keyways I have cut on the lathe have also been done just with the tool no waste removal first. Of you want to remove some of the bulk then turn up an ali plug and put that in the hole, you can then drill down the joint line and the drill should run true. remove plug and carry on as previous. Edited By JasonB on 17/01/2019 16:08:16 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in