Super Steel epoxy

| bernard towers | 19/11/2022 22:26:53 |

| 1221 forum posts 161 photos | I think its the metal one but then who cares not everyone is concerned with steam just the strength and look. |

| JasonB | 20/11/2022 07:26:33 |

25215 forum posts 3105 photos 1 articles | Posted by ChrisLH on 18/11/2022 14:40:23:

I watched a video some months ago on this subject. The guy did tests on various "epoxy putties" but it was US based so may apply to some brands not available here..................................................... Chris have you got a link as I think your video may have been for Putty not an adhesive like the JBWeld being discussed. Although JBW do a putty where two sticks are mixed together the JBWeld generally used for model construction is much more liquid and comes in two tubes. I would think it very hard to use a putty for bonding any close fitting surfaces together as you would have a job closing up the joint although it should be OK for things like adding fillets Bernard, steam does not bother me either but as the question was how does another compare with JBWeld then I was just pointing out a difference in the product I could find on the net. I do sometimes use a bit of JBW on the IC engines though so heat and fuel resistance comes into play there Edited By JasonB on 20/11/2022 07:28:05 |

| Ramon Wilson | 20/11/2022 09:32:14 |

1655 forum posts 617 photos | You are correct there Bernard, not everyone is As I recall I made my first silencer for an IC engine sometime in the early seventies. It was for an OS-40 glow motor fitted in my first model boat. The engine was not a water cooled version but the standard unsilenced R/C motor, the manifold made from brass with a brass collector silver soldered to it leading via silicone tubing to an expansion chamber in the rear of the boat. Well over-engineered in respect to the engine but the only materials available to me at that time. It was much to my surprise that the first run showed that the silver solder had melted with the heat, clearly evidenced by the way the solder had run. What's this to do with JB Weld you may ask. Well, a few years later and well before any use of JBW in an ME application I made another silencer from aluminium for a similar engine - an OS Max 35S. This was for use in a control line model. At an early competition the central bolt that held all three components of the chamber came loose in flight and the silencer left the aircraft - an immediate loss of all points due to the jettison rule. One of the other competitors came over to me after and said something like "JB Weld will cure that" I queried what it was and once told doubted that an epoxy would stand the heat involved. However, well before the use of any computer, I finally found a supplier and bought some. Still with a high degree of scepticism the silencer was reassembled with JBW but still retaining it's central bolt. I was expecting to witness burnt residue around the joints but no, nothing even after many flights. I decided to remove the bolt to see what happens - nothing - it just carried on being a silencer the whole thing held together with nothing more than the JBW. This was my first realisation of just how strong this stuff was in high temp conditions. (Anyone who has used glow engines know just how hot they get). Simplistic? Well maybe but the proof was in the pudding. I have made quite a few silencers since using nothing but JBW. Flown considerably I have had only one failure where the single 8BA cap head bolt holding the silencer itself to the manifold sheared. On first use I grabbed the first thing at hand to mix it on, a piece of flat steel plate, the residue curing in a solid lump. Quite sometime later I looked for a similar piece of steel and thought I could quickly chisel the JBW off. How wrong that assumption proved to be as it was extremely hard and resistant. I gave up and looked for another piece of material,l the JB coated piece still lurking in the workshop somewhere as a good example. It was this prior use and the discovery of just how hard it was that lead me to the conclusion that it would make for a good bonding agent to fabricate 'castings' - the Waller engine, much much later, finally being the first real use in this application. As readers can no doubt surmise - I am a convinced advocate of the product based on a high degree of success with its attributes. Yes there are other products available but none, as far as I am aware, match them like for like at the reasonable cost that JBW is available for. This product has been the subject of other threads before - a quick search of JB Weld will soon find them

Best -Tug |

| ChrisLH | 20/11/2022 10:32:07 |

| 111 forum posts 7 photos | Jason, I misguidedly thought that "epoxy putty" was how you would describe araldite, etc. in the US. Here's a link to the video I watched, you need training at an audio gym before watching as the vocal delivery is super fast. https://www.youtube.com/watch?v=R3r0UZ7txzs (I haven't yet fathomed how to paste an automatic link) The JBWeld product tested was "SteelStik". Is this the grade used by Ramon, yourself and other advocates ? Edited By JasonB on 20/11/2022 12:15:36 |

| Ramon Wilson | 20/11/2022 10:43:44 |

1655 forum posts 617 photos | Chris - it is the standard 24 hr cure JBW that has the best attributes. The faster cure does not have the same strength nor temperature resistance.

|

| JasonB | 20/11/2022 12:24:43 |

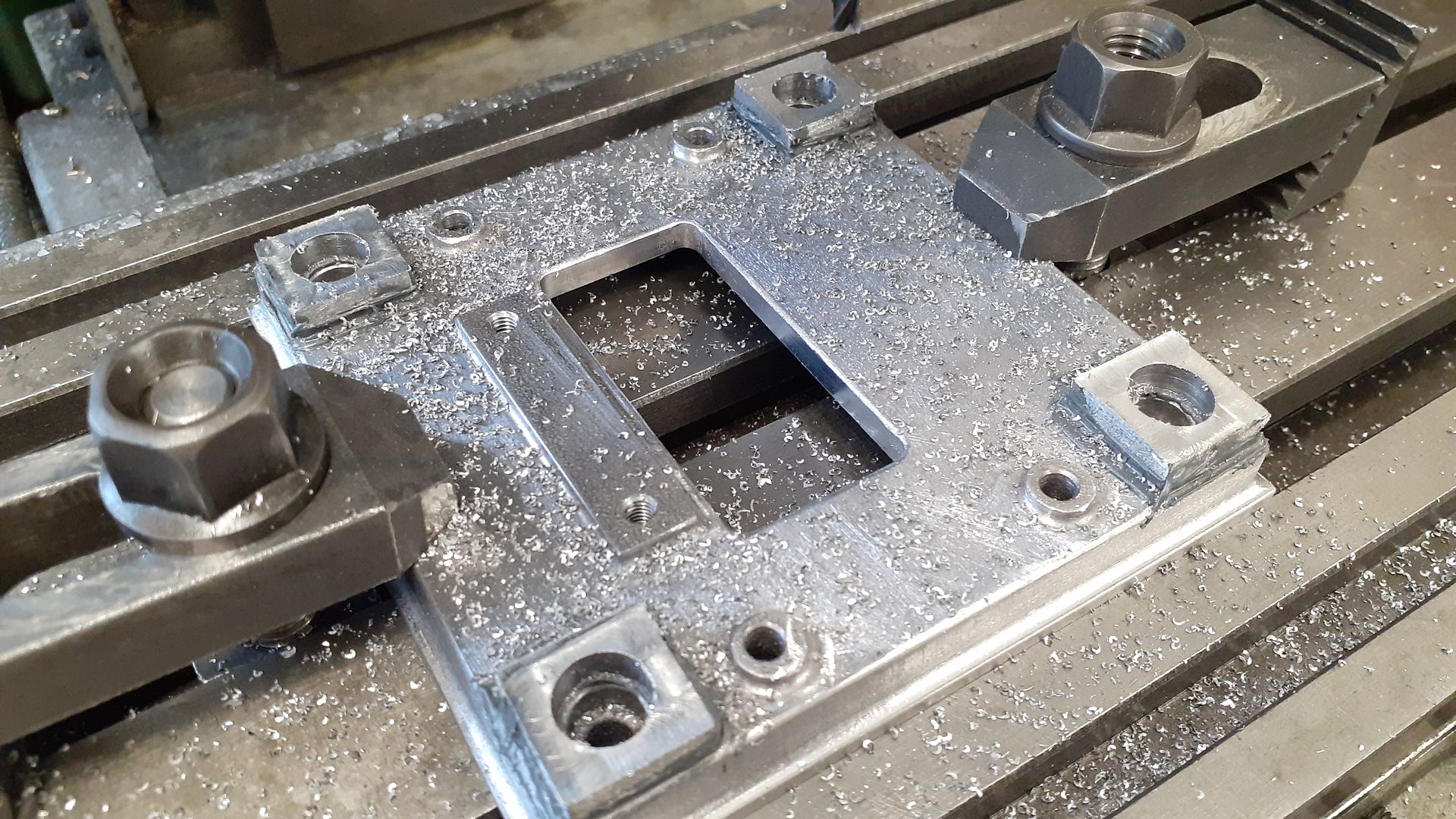

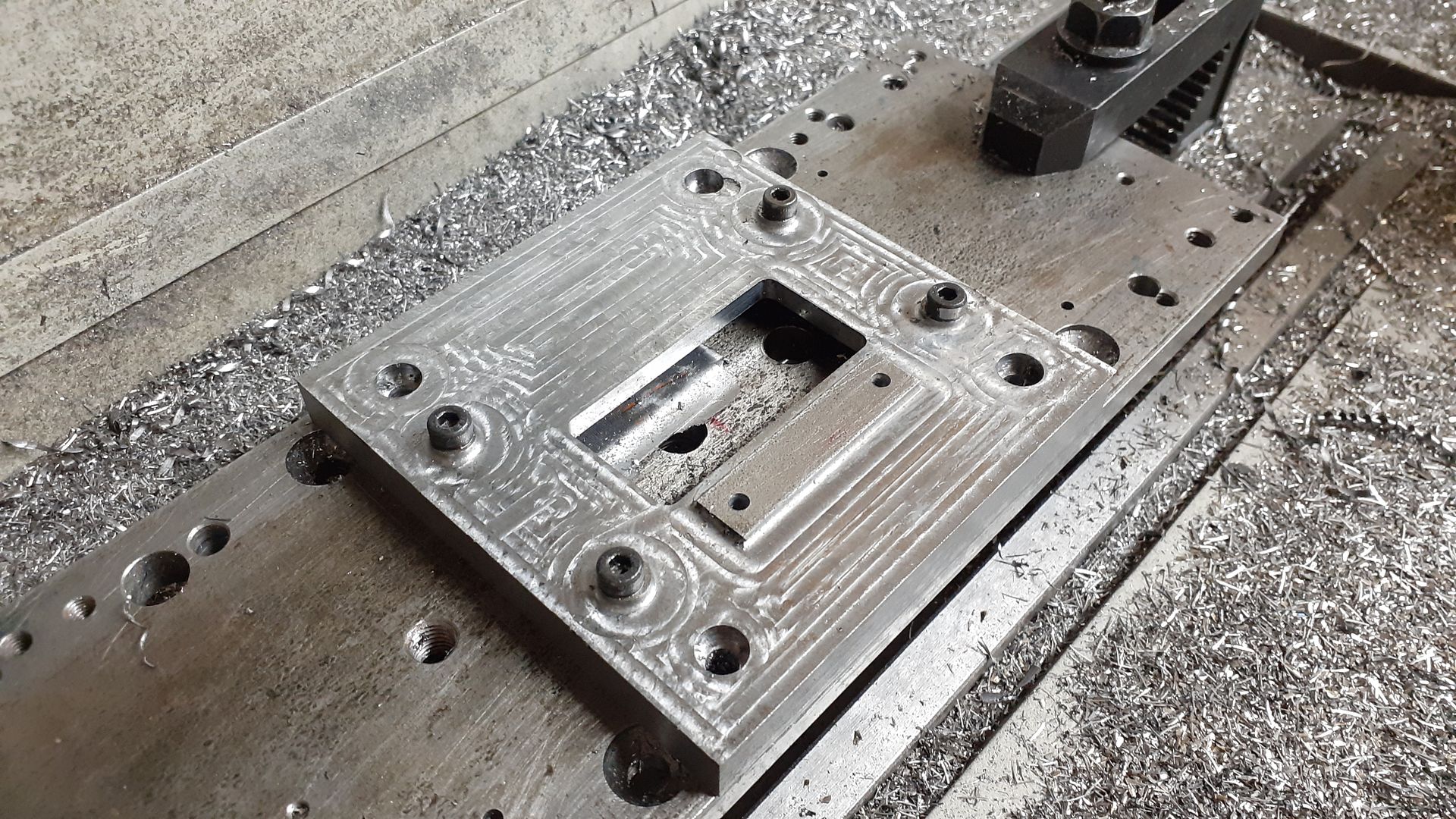

25215 forum posts 3105 photos 1 articles | Thanks Chris, as I thought they are mostly the two part kneadable butties where as the best JBWeld for ME use is as Ramon says the Original Formula which has a consistency more like peanut butter so is good for spreading onto mating surfaces where a thin film is needed. I always try and say which one it is when posting about it such as in this recent thread as the rapid and marine ones don't have the strength or heat rating of the original. I machined the tops of the four squares of steel last week that had been JB welded onto the main plate without them flying across the workshop, so it's sticky stuff. Best not ask Ramon about his soft jaws if anyone is of a delicate disposition

|

| Ramon Wilson | 20/11/2022 13:20:32 |

1655 forum posts 617 photos | Posted by JasonB on 20/11/2022 12:24:43:

Best not ask Ramon about his soft jaws if anyone is of a delicate disposition

Well, they are still in use Jason, used them only yesterday in fact

'Horses for Courses' of course but that old phrase "Don't knock it till you tried it" could be well applied to JBW for sure

PS are kneadable 'butties' similar to bacon ones? Sorry couldn't resist Edited By Ramon Wilson on 20/11/2022 13:22:39 |

| Weary | 20/11/2022 13:45:30 |

| 421 forum posts 1 photos | OK, the challenge has been thrown-down & I'm rough, tough, and unshockable. My 'disposition' is definitely not "delicate". So ........ (although perhaps with a just a little trepidation tho' ).... I'm askin' about Ramon's "soft jaws". (whilst assuming that this doesn't refer to some do-it-yersel' dentistry using JB Weld) Please tell ......?? P'raps you moulded some soft jaws from JB Weld?? Regards, Phil Edited By Weary on 20/11/2022 13:46:04 Edited By Weary on 20/11/2022 13:46:49 |

| Bazyle | 20/11/2022 13:59:01 |

6956 forum posts 229 photos | Off topic but we should all learn from Jason's picture above of glued on bosses how one can save power and time machining and waste less metal as swarf by using that technique rather than, in perhaps more distant future, setting a CNC milling machine to carve it from a bigger block just because it can. |

| JasonB | 20/11/2022 14:07:14 |

25215 forum posts 3105 photos 1 articles | Yes replicating castings in more than one way as they can save raw material too. I did briefly consider cutting it from 5/8" flat but it's a lot of swarf, time and wear to a cutter so settled on using the CNC to cut most from 1/2" flat bar and then added the column bases. I would also have been possible to use even thinner stock and add the round and rectangular bosses too.Though on this occasion I did not stitch drill out the rectangular hole and save the waste for something else.

|

| Ramon Wilson | 20/11/2022 18:12:42 |

1655 forum posts 617 photos | Weary - I think I described this mod on MEM - I recall at least one or two nay sayers doubting the viability of it. I've had two sets of soft jaws for many years. The first well used and gradually diminishing in material the other still wrapped in their VIP paper. The first were reclaimed early on by bolting slices of Hexagon bar on each jaw - a good compromise which works well but even the area they were bolted to eventually disappeared. Just about to ditch them and open that new pack I found a short length of about 1 1/2 x 1/2" BMS under the bench. It was cut it into three lengths then a deep slot was machined in each jaw and each piece just JB welded in place without any pinning or bolting. It was left a few days to cure right through before using. I think this was testing it - the embryo liner for an IC engine They have been in regular use since though at one point well into it's life I thought I felt a movement, a slight give on tightening. No, must have been me as they are still in use though closely reaching another reclaim I fear. Despite the fears of the nay sayers, the inserts have not parted company in use and have saved quite a useful accessory not to mention the cost if replacement was required. Yep JB Weld is a useful tool to have on the bench alright

Tug Edited By Ramon Wilson on 20/11/2022 18:16:56 |

| Ian Skeldon 2 | 20/11/2022 20:43:07 |

| 543 forum posts 54 photos | Having looked through this and related posts on here along with looking at the content direct to via links I am convinced it is at least worth getting some of this stuff in and trying it, so thank you to all that contributed showing their practical use of this glue.

Quick question is it the red or the blue pack that has the highest strength (in practice not on paper etc,) and where can it be bought from? Many thanks, Ian |

| JasonB | 20/11/2022 20:50:57 |

25215 forum posts 3105 photos 1 articles | It's the same stuff in Ramon's photo Just go by the tube colours of Black and Red. I think the different backing is the blue one has safety data for non US sales. I get mine from e-bay, a lot of the performance car parts suppliers do it Edited By JasonB on 20/11/2022 20:52:55 |

| Ramon Wilson | 21/11/2022 08:58:51 |

1655 forum posts 617 photos | Just a thumbs up on Jason's advice to use ebay. For some reason this product seems to attract a considerable variation in pricing from the differing sources - a search on ebay soon shows that.

|

| Ian Skeldon 2 | 21/11/2022 21:34:43 |

| 543 forum posts 54 photos | Thank you Jason and Ramon

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in