Boring a circular groove

| SillyOldDuffer | 29/12/2020 20:14:31 |

| 10668 forum posts 2415 photos | Though Chris said 'groove', I read his drawing as a dimple! As this is a classic engineering problem with 2D drawings, may be worth mentioning the answer. It's to provide two or more views of the object, which together provide all the information needed to derive the 3D shape. Basically, draw what the object looks like from three sides, like plan, front and side: Actually this object only needs two views to show Chris said and meant 'groove'. Far more to Technical Drawing and Draughtsmanship than this example, but the basic idea is simple enough. Jason removed ambiguities by developing the object in 3D CAD, which I generally prefer because the 'real' shape can be viewed from any angle. But 2D drawings are also useful, and good ones are a positive joy to look at - art! Dave

|

| roy entwistle | 29/12/2020 20:44:20 |

| 1716 forum posts | Deleted as inappropriate

Edited By roy entwistle on 29/12/2020 20:46:21 Edited By roy entwistle on 29/12/2020 20:47:45 |

| JasonB | 29/12/2020 20:49:39 |

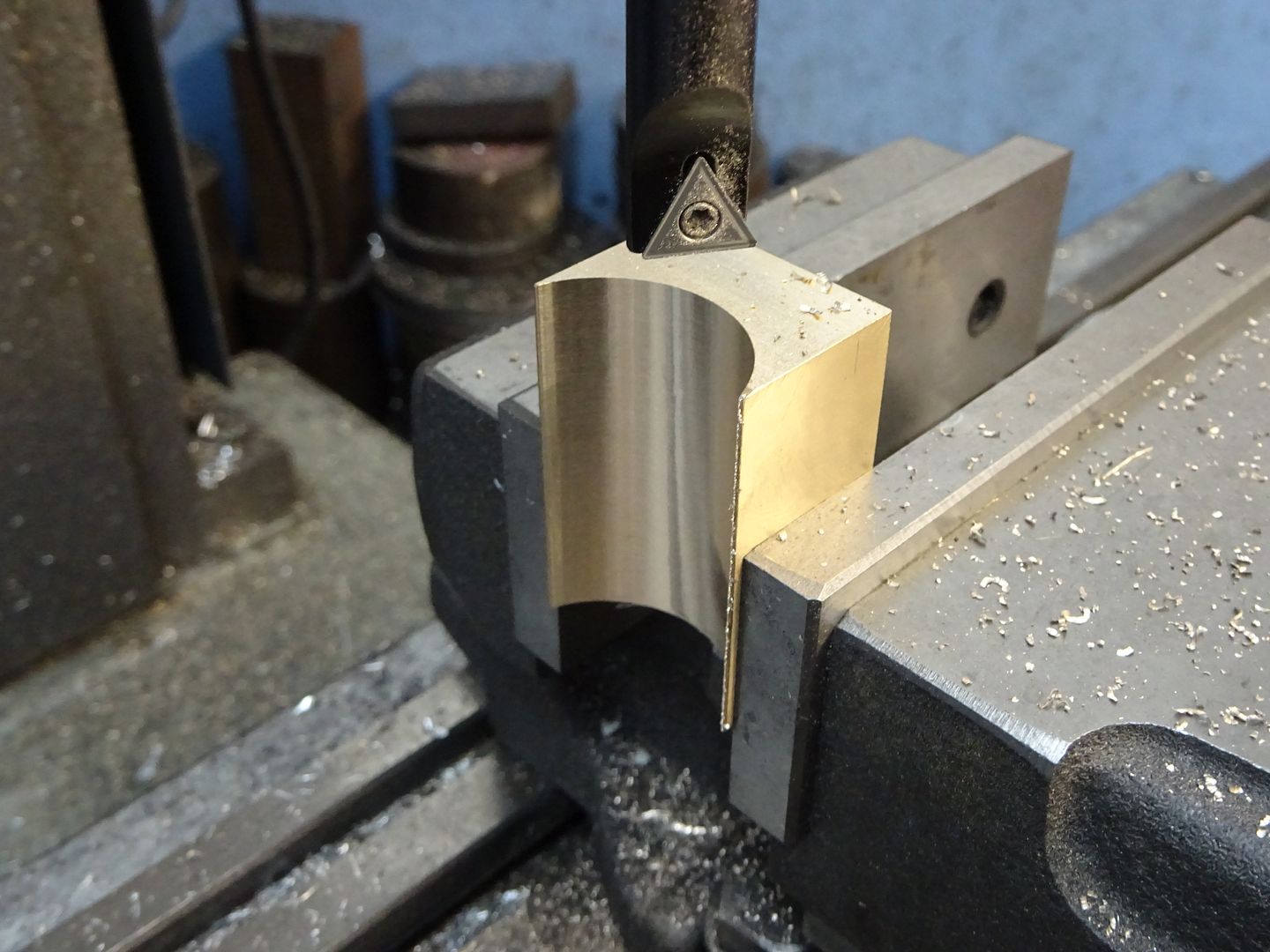

25215 forum posts 3105 photos 1 articles | Although the size in this case would not suit the method there is no reason you could not bore a circular groove

|

| old mart | 29/12/2020 21:04:58 |

| 4655 forum posts 304 photos | Drilling the 2.5mm hole could be difficult if the drawings are similar to the job. That is deep for the diameter. What is needed is a starter hole made with a stub drill and then change to a NEW split point drill of a quality make. Everything depends on the tolerances required. |

| Nigel Graham 2 | 29/12/2020 21:28:36 |

| 3293 forum posts 112 photos | 2D and 3D drawings should complement each other. You need dimensioned orthographic drawings for making the parts, and I regard them as the more important (and easier to draw, manually or in CAD). However, isometric drawings aid visualising awkward shapes, and their real strength is the field of assembly- and explanatory- drawings. It's common now for a small isometric "picture" to be put in some spare blank area on an otherwise orthographic drawing. Hemingway do that with the drawings and constructional notes packed with their kits. ' There is nothing new in that of course. Very highly-skilled users can produce impressive brochure-art from CAD packages like Alibre, TurboCAD and Fusion, but Victorian engineers and architects frequently produced beautiful, tinted drawings (perhaps for the contract negotiations rather than shop or site use). Vehicle service-manuals have long used isometric cut-away and exploded images; and we of bus-pass age may recall the magnificent cut-away engineering drawings forming the The Eagle comic's centre-spread features!. Oddly, despite the possibilities for architectural CAD, public-relations "artists' impression" drawings released by property-speculators now are often a lot rougher and less informative than in the past. Of those CAD packages, TurboCAD (or at least the edition I bought) allows a direct choice of 2D drawing or 3D "model". Its competitors assume 3D-modelling from the start, with some means to extract from the model the elevations needed in the workshop. ' As for "art", just examine some of the huge general-arrangement drawings produced a century or more ago, of railway-locomotives, power-station plant, etc. A wealth of repeated small parts, hidden-detail lines, cross-section hatching, etc - all starting as pencil on paper, with a loose T-square and set-squares. The draughtsmen (not many draughtswomen, at least not at design level) were also expected to be good at free-hand sketching. Even structural analysis was often carried out on the drawing-board, using techniques like Bowes' Notation (which I recall , vaguely, from A-Level) to calculate stress-vectors in frameworks. |

| Emgee | 29/12/2020 21:39:15 |

| 2610 forum posts 312 photos | Posted by Chris TickTock on 29/12/2020 11:35:25:

Hi Guys, thanks for posts for clarity the half round groove goes right across the face in a straight line. Regards Chris It's a bit OTT IMO to need a drawing of any kind to know what Chris wanted when he posted the above. Emgee |

| Ian P | 29/12/2020 22:00:58 |

2747 forum posts 123 photos | Posted by Emgee on 29/12/2020 21:39:15:

Posted by Chris TickTock on 29/12/2020 11:35:25:

Hi Guys, thanks for posts for clarity the half round groove goes right across the face in a straight line. Regards Chris It's a bit OTT IMO to need a drawing of any kind to know what Chris wanted when he posted the above. Emgee Depends on what you mean by 'above'. Chris supplied a drawing that was nearly as undecipherable as his question. Ian P |

| Emgee | 29/12/2020 23:12:01 |

| 2610 forum posts 312 photos | Posted by Ian P on 29/12/2020 22:00:58:

Posted by Emgee on 29/12/2020 21:39:15:

Posted by Chris TickTock on 29/12/2020 11:35:25:

Hi Guys, thanks for posts for clarity the half round groove goes right across the face in a straight line. Regards Chris It's a bit OTT IMO to need a drawing of any kind to know what Chris wanted when he posted the above. Emgee Depends on what you mean by 'above'. Chris supplied a drawing that was nearly as undecipherable as his question. Ian P Hi Guys, thanks for posts for clarity the half round groove goes right across the face in a straight line. Regards Chris ----------------------------------------------- This was the posting referred to as above Ian. Emgee |

| Hopper | 30/12/2020 00:54:51 |

7881 forum posts 397 photos | Seems like you might be able to slide the ballnose end mill up into the collet until only 5mm or so is sticking out so less likely to snap off under side loading. Or to avoid risk of the cutting edges damaging a soft collet, turn up a sleeve to fit over the cutter, slit it lengthways with a mini hacksaw and fit the cutter plus sleeve into a larger diameter collet, again with just the nose protruding. Or grind a radius on the end of a piece of square HSS steel lathe tool bit and swing it in the mill like a fly cutter, held in a piece of round bar like a lathe boring bar. Or Google for "Shank Type Convex Milling Cutter" (sorry, not allowed to post a link or even mention a site name as previous posts have been deleted for doing so.) and find a cheapo cutter that is like a woodruff keyway cutter but with the radius on the ends of the teeth to cut a half-round groove. |

| Howard Lewis | 30/12/2020 13:43:00 |

| 7227 forum posts 21 photos | The possible methods became clearer once the end result had eventually been made clear. The word "Boring" probably threw us off the scent, allied to the lack of clarity of what the desired end result was.. Chris, Sorry to chastise you, but, please take this as advice for the future.: If your definition of a problem is imprecise, the suggestions will, in all probability, not provide the solution that you seek. You need to define the the end result clearly, before asking the question. This one was like like extracting teeth! Howard

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in