Member postings for JasonB

Here is a list of all the postings JasonB has made in our forums. Click on a thread name to jump to the thread.

| Thread: Boiler calculations, end plates |

| 21/09/2023 19:40:19 |

It's the quality home welding that is the issue not the design of plates, tube and suitable welds |

| Thread: Thumb screw |

| 21/09/2023 19:34:46 |

The thumb screw looks thicker than the head of the screw. So drill and tap to the knurled rod to suit thescrew size and then counterbore for the head. Screw the screw into the thread with some Loctite and jobs a good un |

| Thread: Gib Adjusters and the English Language! |

| 21/09/2023 14:18:26 |

Does sound more like a gib headed key though where the gib head acts a bit like a hook to aid it's removal. |

| Thread: Information |

| 21/09/2023 14:02:06 |

Yes those are the MEW issue numbers in the opening post |

| Thread: Stuart 10V |

| 21/09/2023 14:00:38 |

Most Stuart eccentric starps were/are hot brass pressings, not sure of the very latest but they may well be part CNC machined brass the same as the current conrods are but not gun metal.. I'd try and layout the hole inline with the actual rod and see if there is enough material either side to get the clamping bolts in, you could even leave th ebolt out on the solid side as it is only decorative the one on th esplit side is what adjusts the fit. |

| Thread: Warco WM 290v |

| 21/09/2023 11:26:55 |

Thats a metric chart so assume you have a metric leadscrew. so th efinest fee dyou wil get is 0.07mm/rev (0.0028" ) Although I can't see the 20T gear on the inside the rest looks to be right if C is selected Easier way to check is put a Dti against the carriage and wind the chuck say 10 revs after taking out teh backlash and see if the carriage moves 0.7mm |

| Thread: By The Time This Update Has Loaded... (Alibre) |

| 21/09/2023 09:35:01 |

Actually Nigel there are only 5 features that the latest version covers but it also fixes 60bugs so not just adding things you think you won't want. Two of those new features I have already used as I am working on a model where placing text to follow a curve and then wrapping that text onto a cylindrical surface was needed. Also see david's reply which may have appeared while you were typing |

| Thread: DROs etc |

| 21/09/2023 09:23:21 |

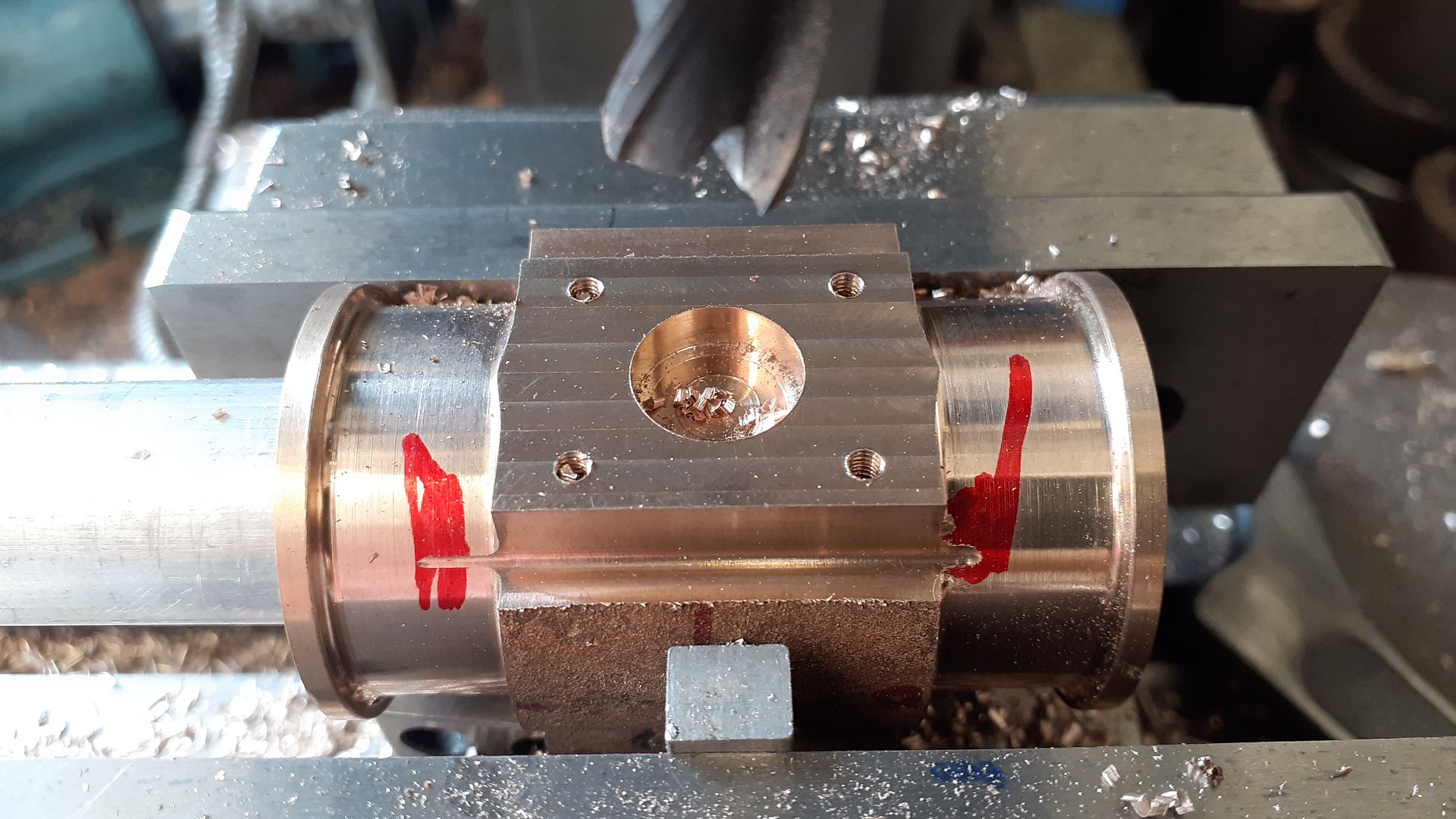

The comment that as model engineers we tend to make one part to fit another is interesting. On the lathe I will often use the part turned first to gauge the size and fit of the second diameter so in that case making one to fit the other applies. However on the mill it is very much the opposite and since fitting the DRO I tend to make each part with that and they fit. The old books and mag articles would generally tell you to mark out and drill one part, then clamp it to the other to spot or drill through into the second and if it were a tapped hole you would then have to open up the initial holes to clearance size. So a lot more long winded and there could be errors in the marking out and picking up those marks. Now with the DRO I just drill say the ends of a cylinder using the DRO's PCD option with tapping size and go round again to guide the tap so it is directly above the hole. Then the covers get done straight away with clearance holes so no need to do them tapping size followed by opening up. I then know that my covers willfit in any orientation as the holes have all been placed equaly and I don't tend to allow much in the way of clearance eg a M3 fixing goes into a 3mm drilled hole. I seldom do any marking out now, usually locate the ctr or edge of the part and then use the DRO to locate any features, lets face it even if your DRO only reads to 0.01mm that is going to be more accurate than most people can use a rule, scribed line, correctly located punch mark and picking up that punched location not to mention a whole lot quicker. Or if using the handwheels to place the features there is no need for compensating for backlash |

| Thread: Gib Adjusters and the English Language! |

| 21/09/2023 06:57:35 |

I've always used Gib as in the Bee Gees Jib is for boats and cranes Edited By JasonB on 21/09/2023 06:58:16 |

| Thread: By The Time This Update Has Loaded... (Alibre) |

| 21/09/2023 06:53:21 |

My V27 update which I did a few weeks ago took about 5mins that is for Pro but would expect the same for Atom. All previous updates have been a similar time and only seem to load the new version not anything else. It generally loads a complete version rather than update the previous but does not take long unless you have a very slow connection Edited By JasonB on 21/09/2023 07:20:04 |

| Thread: Warco WM 290v |

| 20/09/2023 20:44:28 |

You would have to invest in some larger gears and even then it would be difficult to mount them on the banjo. I doubt you will need anything slower than 0.0025", I've not found the need in about 12 yrs of owning the 280 |

| 20/09/2023 20:22:32 |

Post an image of the gear train from the front with the end cover removed and also one of the chart on the lathe, It's probably the same as my 280 but will be easier to check with the chart |

| 20/09/2023 19:28:55 |

Do you have the right hand of the three front levers on feed rather than screw cutting. leaning to the right. This should make the lower feed rod rotate and the threaded lead screw should be stationary Middle lever should be over to the left to give the finest of the three options position "C" Are you using the lever on the front of the apron to engage feed rather than the one on the right which engages the half nuts.

Edited By JasonB on 20/09/2023 19:36:20 |

| Thread: DROs etc |

| 20/09/2023 14:14:09 |

Personally I would fit a DRO to the mill over the lathe any day of the week so save your money until then. Yes it is still possible to do good work with just handwheels but that obviously can depend on the user, my first engine was a Stuart 10V which I still have and that will run simply by blowing into it and was done on avery small Unimat 3 and I'm not an engineer by trade. I do have a DRO on the mill now and would not be without it, have not got round to fitting one to the lateh and quite probably wont. |

| Thread: Milling Advice |

| 20/09/2023 11:19:58 |

Andrew must be buying his cutters from an upmarket supplier, 10mm carbide with 1.0mm radius can be had for just over £20 from the likes of APT and they work for me, even cheaper from other sources. I use them a lot when I want internal fullets to replicate castings and sometimes for flat surfaces

As for the depth of cut question it sounds like the cutter is past its best or the machine not that able. maybe try 0.5mm and less stepover between passes combined with the slower speed and rigidly mounting the work. Edited By JasonB on 20/09/2023 11:23:15 |

| Thread: Information |

| 20/09/2023 11:10:06 |

The articles are about converting to taper roller bearings |

| Thread: Milling Advice |

| 20/09/2023 10:09:59 |

0.2mm is a bit shallow and will tend to just wear the very corners of the cutter, What was the total depth you wanted to remove? |

| 20/09/2023 10:05:28 |

If it is just visual than the mill is OK but often if tram is out eg the spindle is not vertical above the work you can get a saw tooth effect, even if very small you can usually feel it with a finger nail, this is an exaggerated sketch. Just noticed you have the work screwed to a block of wood. This will likely be allowing the work to be pushed away from the cutter as the setup is not totally rigid and that won't be doing anything to help the finish. |

| 20/09/2023 09:11:19 |

Check the tran and nod as the ridges are often due to the cutter leaning sideways. Lock evey way that is not moving but I suspect it is about a sgood as you will get with that combi machine. Also half the speed if that was with a HSS cutter you may not blunt it as fast then. You want a speed of no more that 30m/min, at 2000rpm you were doing 62m/min (200ft/min) |

| Thread: Play in new arbour for mill |

| 20/09/2023 08:46:21 |

Last couple of replies moved to new thread here |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in