Member postings for Paul Boscott

Here is a list of all the postings Paul Boscott has made in our forums. Click on a thread name to jump to the thread.

| Thread: What are you building? |

| 20/09/2010 21:05:15 |

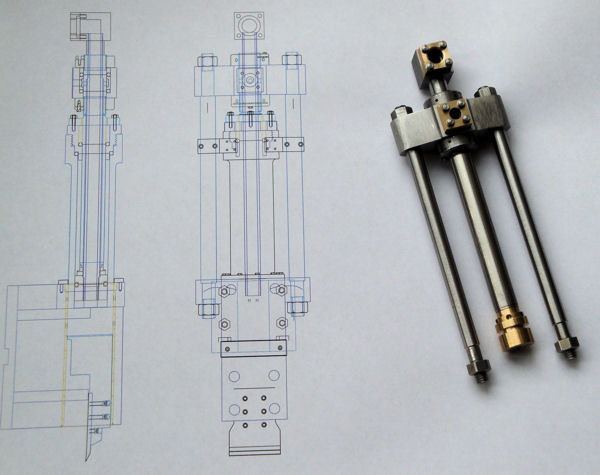

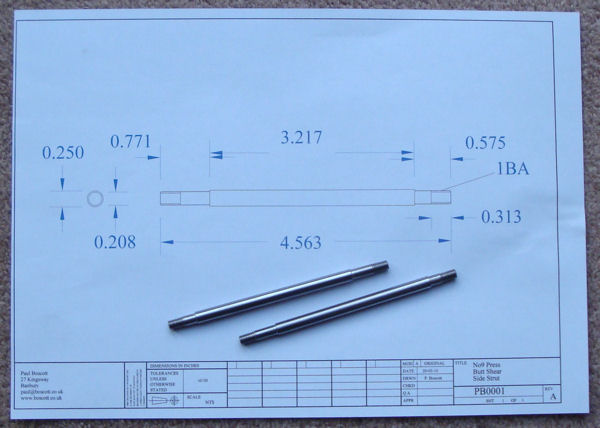

I'll use this thread to give you an update on the extrusion press that I am making. The butt shear is finished and working see http://www.boscott.co.uk

I am still looking for information any thing may be usefull I am putting together a stand to show the pictures I have of the press at the Banbury Model engineering exhibition on 9th Oct 10:00 to 16:00 at St Mary's Church Banbury I will also have on display some of the other models I have made in the past.

Paul Boscott |

| Thread: Extrusion Press |

| 14/09/2010 13:34:33 |

John

Thank you for your intrest I am making a drawing sheet for each part as I go. I have drawn up the compleat press assembled using AutoCad to ensure that the bits wil all fit togeather before I statred to machine any thing

Paul |

| 12/09/2010 21:53:30 |

Just to let you know that progress is being made check

I have tested it using compressed Air and it works correctly

|

| Thread: Making studs |

| 08/09/2010 13:17:38 |

Peter

I do as Bogs but use a split threaded brass mushroom and no locknut the flange of the mushroom is against the chuck jaws to the fix the base of the thead in a known positoin then tightning the chuch locks the stud in position the play in the tail stock die holder centers the second thread

I find it better to use studs that threaded bar as it makes the hight of the stud independant of the depth of the treaded hole and you can more easly get the two threads above the nut.

Paul Edited By Paul Boscott on 08/09/2010 13:21:53 |

| Thread: David Clark |

| 23/08/2010 17:47:45 |

Steve

I have arrived a bit late to offer my name as a second But David gets my vote.

Paul |

| Thread: Actual diameter of 13/16" die holder in wrench |

| 11/08/2010 10:59:04 |

Hello All

I am also intrested in the answer to the original question as I made a tailstock die holder with what must have been to much clerance as I spread a die it cracked in two

Paul |

| Thread: Workshop Electrics |

| 07/08/2010 11:31:03 |

Kwil

Unfortunately those of us that think we can complementally do the work get caught in the cross fire resulting from the necessity of protecting the public at large from cowboys.

But even I had to borrow an earth loop tester as that measurement cannot be guessed and with out a low enough earth return path an RCD will not trip at the designed speed so as to afford the specified protection.

Paul

|

| Thread: Bead/shot blasting. |

| 07/08/2010 10:41:35 |

Paul Beg, borrow or buy  "How not to paint a locomotive" I think there is a good write up of the problems surrounding Blasting "How not to paint a locomotive" I think there is a good write up of the problems surrounding Blasting Paul |

| Thread: Workshop Electrics |

| 06/08/2010 14:56:35 |

Chris is correct that you can do the actual work yourself BUT you MUST have it signed off by a qualified person. The catch is if it is not inspected, tested and singed off and there was a problem with it the house insurance would be void. |

| Thread: how do you scale up drawings |

| 01/08/2010 18:37:43 |

Nigel Considering the many hundreds of hours and pounds you will spend to make a good job of such a project I would suggest that you invest in a proven set of correct size drawings. Paul |

| Thread: Extrusion Press |

| 25/07/2010 20:31:48 |

Model finish How accurately should a model reflect the finish of the original? The quandary that I have is that the finish on the actual extrusion press that I am making as a 1/12 scale model is in some places where it did not matter is to say the least is rough some of the parts have been flame cut and the rough edges smoothed of with an angle grinder though the mating faces were surface ground. see http://www.boscott.co.uk/photos.html I have heard the fitters at the time refer to this as Russian tank manufacture (a reference to the system where the finish is only controlled by the actual engineering requirement to minimise workshop hours) My question to you as model engineers is should I reproduce the machine as it actually was or should I improve the look of the finish to a better standard? |

| 04/07/2010 18:40:19 |

At last a weekend in the workshop see http://www.boscott.co.uk/modelphotos.html

Paul |

| Thread: Can you easly Silver solder to EN1A |

| 04/07/2010 07:51:58 |

I want to make a steel fabrication to simulate a casting is it practical to machine parts in EN1A and Silver solder them together ?

or is there a method more normaly used?

Paul |

| Thread: Diamond tool holder. |

| 03/07/2010 14:07:31 |

All

Just got a Diamond tool / holder from Eccentric Engineering UK it works very well

Paul |

| Thread: Home page layout |

| 24/05/2010 20:08:06 |

Seconded

Paul Boscott |

| Thread: Feed Back |

| 15/04/2010 17:59:15 |

Hello David The reading of the smoke rings section of ME 4375 prompts this. I think that you are doing a good Job I find the range and level of subjects well balanced I read the magazine cover to cover adds and all you never know where that little gem that will pull you out of a problem may come from. I have followed the 3D cad articles with interest though I already use AutoCAD for my designs. I like the days out descriptions and the articles about general engineering. I am in complete agreement with you about the safety side of things whilst not being blasé about the subject practical common sense is just as useful as strict adherence to rules. So in conclusion just keep doing it as you see it for me you are winning much more that you are loosing 95% - 5% Paul Boscott |

| Thread: Scaling Down |

| 03/04/2010 12:09:16 |

David

The answer that I got when asking a similar question was

3 1/2" gauge is usually modelled at 3/4" =1ft

5" at 1 1/16" =1ft (although some people use 1"=1ft) 7 1/4" at 1.5" =1ft Somthing that I have done recently that has been realy usfull

(I am making a 1:12 scale model see http://www.boscott.co.uk)

was to draw in the cad system the set of BA nuts and bolts at 1:1 then scale them by * 12.

Drawing the model at 1:1 then when I reduce the model by 12 the BA sizes will be in place and correct.

Paul |

| Thread: Extrusion Press |

| 21/03/2010 08:11:46 |

Hello All

Project on schedule drawings 90% complete and first two parts made seehttp://www.boscott.co.uk/index.html

Paul

|

| Thread: Simpler the Better -what do you use? |

| 20/02/2010 06:40:23 |

I use auto cad 2000 the main advantage is that there is lots of documentatation It has done all the things that I have been able to think of in 2 and 3D

Paul |

| Thread: Perpetual Motion |

| 12/02/2010 20:14:25 |

I would like to take this old chestnut down a different route whilst I assume that most of us will agree that perpetual motion can not exist. What about free energy along the lines of something powered by the gravity or light or some other force that is currently not tapped? Not perpetual motion but just a decade or so.???

Paul |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in