Member postings for AJAX

Here is a list of all the postings AJAX has made in our forums. Click on a thread name to jump to the thread.

| Thread: Adcock Shipley Bridgeport motor |

| 29/01/2022 06:50:39 |

Standard cable ties (non heat resistant) made from 66 nylon are suitable for use up to 85 degrees C. I would remove those ties and use string sprayed with conformal coating, or use heat resistant ties instead. You won't know what is happening inside the motor until it fails. |

| Thread: Qualters and Smith Qdm750 Restoration |

| 27/01/2022 21:54:22 |

You've done a great job there, Pete. Makes mine look rough by comparison but then again at least I'm not afraid to use it. The back gear came in handy when I had to drill and tap lots of holes last week. For anyone considering one, these are very nice drills. I've always assumed they would be on a par with Meddings but I happened to pick up a Meddings drill recently and it's yet to be seen which one I keep. |

| Thread: Can you identify this? |

| 25/01/2022 21:01:09 |

Posted by old mart on 25/01/2022 13:36:53:

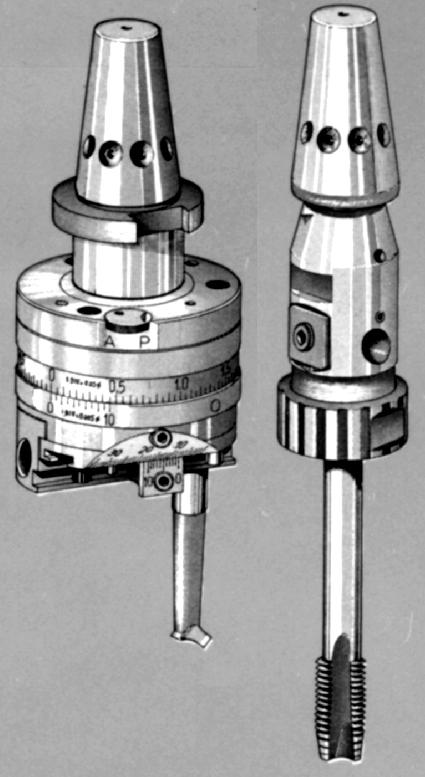

I'm very pleased to know the answer. Me too, but now I've checked the Aciera 22 drilling machine web page I feel short-changed by having only the tool holder! They look very nice machines. |

| 25/01/2022 13:00:00 |

Posted by Versaboss on 25/01/2022 12:32:10:

It is good being active on other forums also. I suspected having seen that before, but did not remember where. So I asked around, and in a couple of hours I got the answer. This quick-change taper belongs to an Aciera 22 drilling machine. See here Kind regards, Edited By Versaboss on 25/01/2022 12:32:58 Well done, Hans! This page shows an example tool holder http://lathes.co.uk/aciera22/page2.html

|

| 24/01/2022 18:51:51 |

Posted by old mart on 24/01/2022 18:02:23:

I did find out what the taper was, but have forgotten and checking through googled machine tapers has not had any luck for me. If I can find the one at the museum, I will post a picture. Edited By old mart on 24/01/2022 18:04:28 Thanks. But unless someone has a use for this taper it will be removed and replaced with a straight shank. |

| 24/01/2022 18:42:37 |

Posted by Tony Pratt 1 on 24/01/2022 09:51:05:

Hi AJAX, are there any markings on the part? Tony None that I am aware of. I will post an update if I see any. |

| 23/01/2022 22:23:47 |

Posted by old mart on 23/01/2022 21:14:01:

There is one of those tapers kicking around the workshop at the museum, I believe it is for a quick release milling or maybe drilling spindle. It is probably one of the short lived fittings that were killed off by BT 30 AND 40. The DTI holder would work well on any mill spindle or lathe tailstock. I would get a blank end arbor to fit it on as the blank ends are made soft to be machined. Edited By old mart on 23/01/2022 21:15:05 Edited By old mart on 23/01/2022 21:16:23 Now you've mentioned it, I think you're right. Many thanks.

|

| 23/01/2022 20:41:27 |

I have a "thing" that most probably belonged to a larger thing. Some parts bear a similarity to those found on a scribing block or indicator stand. I'd be most interested to know what the indexed conical part is for. The dovetail and gib strip has a very smooth fit. It appears to be well made. |

| Thread: Adcock Shipley Bridgeport motor |

| 16/01/2022 21:10:22 |

I've taken apart quite a lot of single and three phase motors, but I don't claim to be an expert. As the data plate states this can be wired for 220v or 380v operation then it should be possible to change some links somewhere. I suspect if you open the motor up you'll find links behind the wiring box. If so, you should be able to wire for delta operation. As an aside, here are two good books you may find useful. Electric motors (16) and electric motors in the home workshop (24) in the workshop practice series.

|

| Thread: 180v motor not working on new control board |

| 16/01/2022 14:08:25 |

Posted by John Haine on 16/01/2022 13:54:13:

That looks like a tidy new motor. I'm intrigued that it's a DC motor rated at 50/60 Hz though... How many connections does it have, and does it have a field winding? Perhaps it is a universal motor, but being sold as a DC motor? Greenmaster doesn't appear to be a brand or manufacturer with any data sheets. |

| 16/01/2022 10:27:41 |

If after this escapade you wish to continue with DC motors but keep your costs low, I recommend looking around for a used / spares only treadmill on Facebook marketplace. They are frequently available for very little money, sometimes free. I suggest keeping the running belt as it can be repurposed for many tasks. Best of luck, Brian |

| 15/01/2022 15:04:57 |

The motor is rated for 4000 RPM and I'd guess that may be a bigger problem. Or do mini mills have significant reduction by the way of pulleys or gears? I have no experience using one. |

| Thread: Aluminium Composite Material |

| 15/01/2022 15:00:47 |

Posted by Samsaranda on 15/01/2022 14:10:04:

I would think a laser cutter more suited to this but dependent on what the core material is. Dave W We aren't allowed to laser cut PVC at work due to the toxic fumes this releases. At home I've CNC machined panels in pvc electrical enclosures with no problems at 8000 RPM |

| Thread: Getting into the Meddings MF4 Pillasr Drill gear box |

| 15/01/2022 07:21:47 |

Posted by Adam Harris on 12/03/2015 16:46:08:

I do have the exploded parts diagram for M series Meddings drills and I am wondering if I should be trying to remove the selector shaft that is gripped by the selector lever and then just pull the whole gear assembly out attached to the top gear plate but to do so is not obviously possible since the selector shaft appears held firmly in place by a clamping bolt that is only accessible once the top plate is removed. Adam, I need to examine and possibly repair the gearbox of a meddings M5. Before I remove the top plate, could you possibly share that exploded parts diagram and any further useful information you may have? Many thanks, Brian |

| Thread: Meddings pillar drill value |

| 11/01/2022 21:34:08 |

Almost forgot, I sold a bench mounted startrite drill last year. Single phase and probably very similar in build quality and performance to the Meddings. I paid £60. Sold on at a profit, but nothing like £700!! |

| 11/01/2022 21:24:24 |

Posted by Martin Pyke on 10/01/2022 22:45:50:

Could anyone please give me an idea of the value of this Meddings drill. It would a good condition and was fully serviced about 3 years ago when it was bought from a college. It is up for £700 and I am looking at this or a new Axminster Trade drill at £500.00 It will mainly be for small projects using timber and aluminium.

It may be decent quality, but I would not entertain the idea of spending £700 on this drill. If bought direct from a college, the buyer probably paid about £50 - £150. There should be considerable room for negotiation if you really want it. Sold on eBay, it will not realise anything like £700. I sold a nice floor standing Meddings drill recently for about £300. It was an ex school/college machine and was nice to use but as others have noted the lack of a back gear limits usefulness when metal working. Regarding ex school equipment, the annual service is typically a squirt of oil, check safety guards and interlocks and not much else. I doubt the"full service" was any more than a wipe over and possibly a new belt (though that's unlikely if school use was light). I bought an Elliott progress drill a while back. Paid £25 and did it up and now it looks great. Not much different to what you have here. I suggest you have a look around and don't make any quick decisions.

|

| Thread: Bench grinder to polisher |

| 03/01/2022 17:26:51 |

Posted by colin hamilton on 02/01/2022 10:44:49:

So I'm looking to convert my bench grinder to a polisher. I see you can buy tapered spindles that go onto the grinder spindle. Are these any good? Are they held on by the grub screw or do they screw on? Is it possible to make on my lathe if I don't have a taper turning attachment? Thanks I bought some cheap mops from eBay or Ali express and was able to mount them directly to the grinder spindle using the existing nuts. Quality was good. I may have turned some washers/spacers to provide a good clamping force. The only drawback of this method (as opposed to tapered spindles) is the mops are more difficult to swap over, if that's what you need to do. I have previously bought some tapered spindles online from a UK supplier (manufactured in India) and they were absolute junk. Supplier name *roops *ros if you wish to avoid them. |

| Thread: Adjusting the horizontal mill |

| 03/01/2022 12:08:58 |

As an aside, I just noticed you are running a Tuscan flame proof motor. I saw one of these for sale cheaply not long ago but was put off by thoughts of sealing/heating, although maybe they are not so different from TEFC motors. Do you find it works well for you? |

| 03/01/2022 12:04:59 |

Posted by Steve355 on 03/01/2022 11:25:51:

Posted by Dave S on 03/01/2022 10:49:20:

How is the feed taken off? Could you change the spindle pulley and a subsequent feed pulley to give a more appropriate ratio? Dave I don’t think so, the feed pulley for the spindle is about as small as it can be and the spindle pulley is about as big as it can reasonably be. See pic below. I feel a vfd coming on, wallet is getting worried. I'm rather late to this thread, and this may have already been discussed, but that intermediate stepped pulley on the countershaft looks like it may be too big. If be tempted to try a smaller pulley if you have one.

Otherwise, as you already realise, a VFD may be a good option. I chose a VFD and 8 pole 3 phase motor for my horizontal mill as these motors have plenty of torque at low speeds (680 rpm at 50hz). |

| Thread: Recomendations for a Keyless Chuck? |

| 30/12/2021 23:12:44 |

I have a vintage Rohm that works fine. I used to have a bench mounted pillar drill fitted with a keyless chuck purchased on Ali express. It was good for the price (probably £20 ish) |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in