Member postings for Ron Laden

Here is a list of all the postings Ron Laden has made in our forums. Click on a thread name to jump to the thread.

| Thread: Bigger table for a small mill |

| 01/11/2019 08:35:01 |

My SX2P mill has M6 tee nuts which work but seem a bit feeble on heavier jobs, I found that M8 coach bolts are a close fit in the table slots. The round head just needs a couple of flats machining to allow them to slide in, I use them most of the time and they are much stronger than the small M6 tee nuts and studding, cant see a problem with them. Edited By Ron Laden on 01/11/2019 08:37:43 |

| Thread: Simple Vice Stop |

| 31/10/2019 17:32:12 |

I made myself one this afternoon, its a bit shorter at 25mm simply because I had some 1 inch x 3/8 inch bright bar so took a couple of slices off that. I dont have a 3mm reamer so I turned up a couple of pins for a good fit into the drilled holes. I have some repeat parts to mill in the morning so it should be put to good use. Thanks Jason. p.s. forgot to say I fixed the pins to the block with 638, which worked fine. Edited By Ron Laden on 31/10/2019 17:35:12 |

| Thread: Class 22 Diesel (next project) |

| 30/10/2019 16:53:20 |

I am thinking of moulding a couple of parts and giving JB Weld (original) a try as the material but before I do I wonder does it machine and tap ok. I have filed and sanded it in the past and its fine but never machined or tapped it, the parts wont be heavily loaded so as long as I can get a half decent thread for fixing it will be fine. |

| Thread: Little '36 Midget Build |

| 29/10/2019 18:20:45 |

That looks a treat with colour added and the pair of stands are rather eye catching, sounds sweet as well, very very nice indeed. Ron |

| 28/10/2019 19:45:29 |

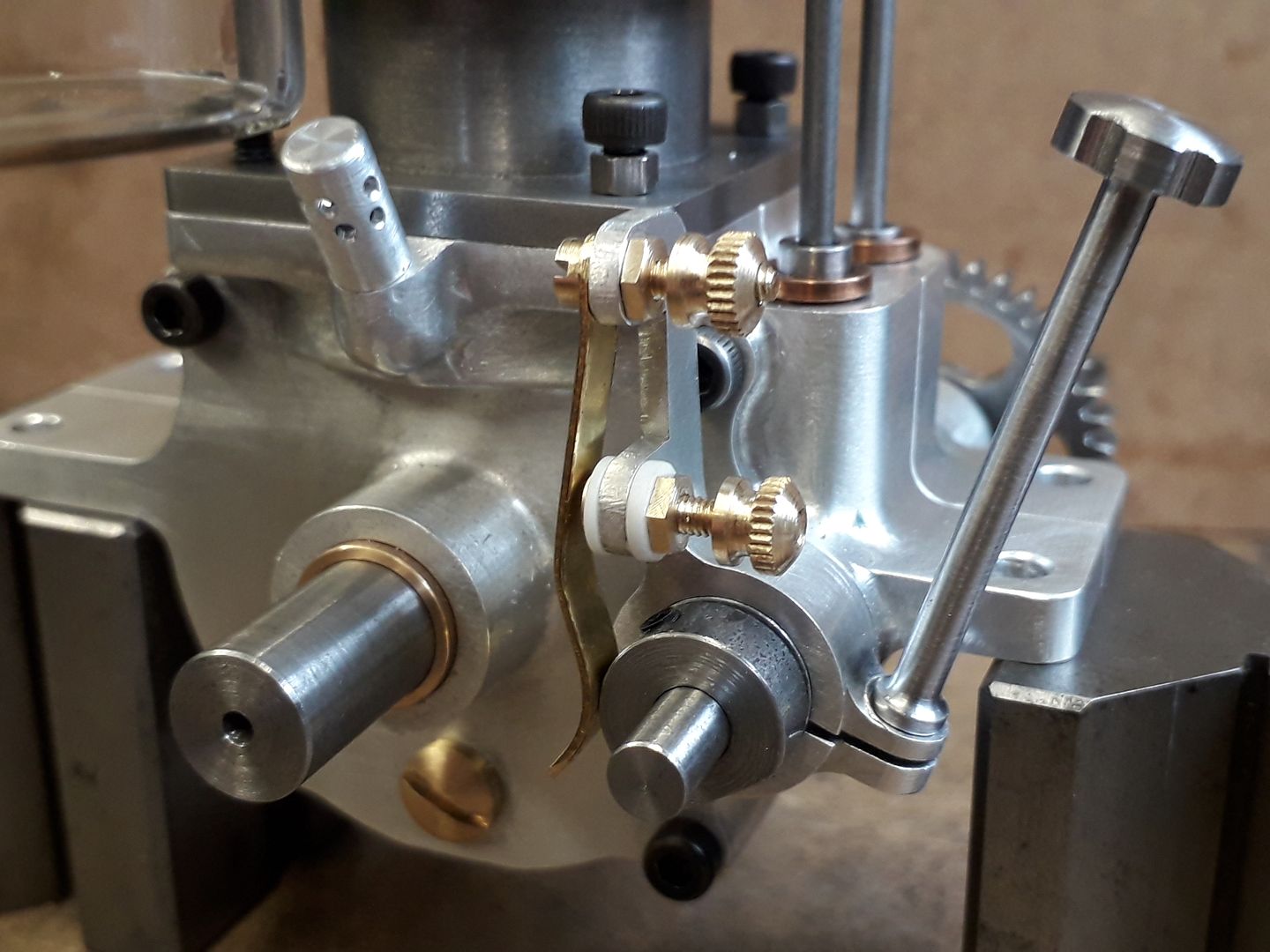

Posted by JasonB on 28/10/2019 19:06:38:

Some brass hardware was turned and a steel screw to allow the clamp to be adjusted so the timing could be advanced or retarded and a couple of Corian insulators completed that assembly.

Thats impressive Jason, I can see some very nice engineering there, some ingenuity also. Ron Edited By Ron Laden on 28/10/2019 19:46:05 |

| Thread: My new lathe a Warco 918 |

| 28/10/2019 09:51:00 |

I am just fortunate Michael, the shop made rear tool post which came with the lathe is fitted with a pair of dowel pins which aligns the post pretty much spot on square to the lathe axis. Providing the tools are parallel and true which the ARC parting tool is, good alignment is assured once mounted in the post. |

| Thread: Mills with tilting heads..? |

| 27/10/2019 18:53:16 |

Thanks Ketan, that is helpful. Ron

|

| 27/10/2019 14:58:42 |

Thanks Jason, as you know I dont have a lot of workshop space so that is something I also need to consider. If you get a minute could you tell me the dimension from the rear of the column to the front of the base casting. I know the overall dimensions from ARC,s website but it would be good to know the mills footprint for the minimum bench space required. Ron |

| 27/10/2019 10:18:02 |

Its no intrusion Michael, I see what you mean you only have to glance at it to see how well engineered it is, it may be small but I doubt it will have any rigidity issues, it looks seriously heavy duty with a build like that. Very nice indeed. Ron |

| Thread: My new lathe a Warco 918 |

| 27/10/2019 09:23:35 |

I was parting some 35.0mm x 2.0mm thick steel washers/spacers for the class 22 bogies this morning and with the ARC insert parting tool working so well mounted in the rear tool post I was curious as to how thin a disc I could cut. Using the 35mm steel I did a bit of a test, tried to cut 0.010" but part way in the disc distorted, so increased to 0.015" (finished at 0.016" ) and it worked a treat, quite impressed that it would part down that thin. Edited By Ron Laden on 27/10/2019 09:24:13 Edited By Ron Laden on 27/10/2019 09:24:43 |

| Thread: What to do with a stationary engine |

| 27/10/2019 08:26:03 |

Excellent that looks like loads of fun. |

| Thread: Mills with tilting heads..? |

| 27/10/2019 08:04:56 |

Thanks guys for all the advice, I wont let avoiding a tilt feature limit my choice. I cant see me using a tilt that often but as one or two guys have said it can be useful. I quite regularly tram my SX2P so wouldnt have a problem doing that when changing from tilt back to vertical. The reason I mentioned rigidity is even with my limited experience I have come to the opinion that with lathes/mills rigidity is king and I just thought of a tilt connection between the column and head as a potential weakness but if its well engineered I guess its ok. Another machine on my list is the Sieg SX2.7 mainly because it is a fixed column with no tilt but looking at ARC,s pictures the SX3 appears to be heavier duty in comparison. I do realise of course that the machines I am looking at are hobby machines and they are what they are but as I am a bit paranoid about rigidity Edited By Ron Laden on 27/10/2019 08:20:11 Edited By Ron Laden on 27/10/2019 08:20:50 |

| 26/10/2019 10:19:35 |

I have been thinking about going up in size from my SX2P mill, I,m not in a rush probably some time next year. So I am spending some time researching what is available and making comparisons. One thing I have noticed is a number of machines in the size I would be considering have tilting heads, for instance the Sieg SX3 which is one on the list now has this feature which it didnt on the previous model. I am a bit hesitant at mills with tilting heads, is it an area for loss of rigidity..? Also when using the tilt (cant see I would use it much) can the head be easily brought back to correct alignment or is it a case of having to tram the mill..? My hesitation is maybe unfounded so I would appreciate any ones experience or thoughts on tilting head mills. Ron |

| Thread: Australian Model Traction Engine Rally 2019 |

| 25/10/2019 09:05:25 |

Paul, looked like a nice collection of engines do you have any more footage..? Ron |

| Thread: H/V or tilting rotary table. |

| 25/10/2019 08:48:35 |

Dennis, my mill is the SX2P and my H/V table is a Soba 5 inch model which I think is just about right size wise for the mill. I started with a 4 inch cheapie and to be fair I have done a few jobs on it but the cheap ones really are not very good at all. The 5 inch came as a set with a chuck, dividing set and tail stock it cost £300 and is very good, well made and accurate. You can of course pay a lot more for tables but the Soba suited my budget and I guess it is in the mid price range for a decent table. So my two penneth for the SX2P is the 5 inch is a good size, 6 inch would be too big and for me the 4 inch is a bit small. Also buy the best you can afford and dont be tempted by the cheapies unless funds wont allow anything better. Ron |

| Thread: Class 22 Diesel (next project) |

| 24/10/2019 09:17:36 |

As well as the starter pack, I see from CuP,s website they also do 455 in paste form, recommended for small or awkward parts. I wonder if that would also be worth getting I can see how that could be useful but as I mentioned I,m new to all this. Edited By Ron Laden on 24/10/2019 09:18:08 |

| 23/10/2019 20:28:07 |

Thanks guys, I will order a starter pack from CuP, sounds good. Ron |

| 23/10/2019 16:33:50 |

I need to silver solder a hex head bolt to a 3mm steel plate, assuming thats possible of course..?, having no experience with silver soldering I would appreciate some guidance on suitable solder and flux type. Ron Edited By Ron Laden on 23/10/2019 16:34:21 |

| 22/10/2019 10:00:37 |

I have put the traction engine to one side for now to put some time into the class 22, the loco is a much quicker build and it would be good to have it finished for late spring next year. I made up and fitted 3 frame spreaders, of which the 2 end ones also serve as buffer plates. The chassis is very simple 2 x alu angle side beams 2" x 1" x 3/16", 2 x steel bogie mount/swivel plates 3" x 1/2", 3 spreaders 2" x 1,2" alu bar. The top of the chassis beams will have 3mm steel plates connecting it all together, simple but strong. Just started making up some detail parts for the bogie side plates plus the sides of the chassis beams.

|

| Thread: Little '36 Midget Build |

| 20/10/2019 20:00:52 |

I am impressed Jason, I would never have imagined a one piece crank coming out of a piece of bar like that. |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in