Lathe spindle speed and finishing speed/feed

Is there a quick rule of thumb?

| Men Ifr | 19/12/2018 09:31:55 |

| 119 forum posts 10 photos | I've been looking for but struggling to find a quick rule of thumb for lathe spindle speed. Something like work diameter divide by 1000? Also how do I change parameters for finishing cuts? Higher spindle speed plus less feed rate? What is the practical limit for this? |

| John Haine | 19/12/2018 09:59:19 |

| 5563 forum posts 322 photos | Try this: In the first post is a link to a table. |

| Men Ifr | 20/12/2018 12:19:34 |

| 119 forum posts 10 photos | That's useful though may be good to know if that's for HSS or carbide tools and there are no feeds.

I found this very useful diagram from cnccookboook

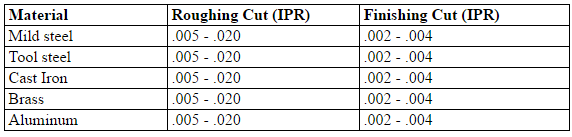

So the surface finish would seem to be limited by a feed so slow that the tool rubs not cuts and spindle speed limited by tool temp What's interesting is I've turned parts with much higher spindle speed than the the table from the 1st link with no problems - if that is a table for HSS tools should it be multiplied by 4 for carbide (even cheap carbide) tools? Is there a limit surface speed for aluminium because it melts? I've took feed rates below

Which gives 0.5 to 0.05mm/rev in metric

|

| JasonB | 20/12/2018 12:29:20 |

25215 forum posts 3105 photos 1 articles | This went with the table THE CNC table is more likely for milling than turning. And your feed chart is a bit high for most hobby use, try about 1/5th of that. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in