Member postings for Rainbows

Here is a list of all the postings Rainbows has made in our forums. Click on a thread name to jump to the thread.

| Thread: Flood coolant for a horizontal mill, minimum pump power? |

| 16/10/2017 11:54:45 |

To steal from the well known Joseph Noci

Ultimately the machine is gonna have this sorta stand. As a temporary measure its getting a basic box section stand with a steel top and wood shelves. After getting some practice at sheet metal work though I want to make something of Noci grade finish with a drawer, cupboard, worklight and flood coolant. Any motor I can have a return valve if I find its overkill though. |

| 16/10/2017 03:18:19 |

Hey its about 2 and a half years since one of my first forum posts about trying to attach flood coolant to a Super Adept, how times have changed. Now for the Centec. I want something that can blast chips out of whatever slot I am cutting. Had a look about ebay, there was an old colchester pump at 240V, 0.3A for a 66W power. I can see 60W oil pumps on ebay for only £20 though I imagine duty cycle wouldn't be as good. The £20 pump advertises 0.8MPA at 4L/min. As a reality check would this sort of pump work? I'm hoping to get a fair bit of pressure for chip clearance rather than just a gentle drip, though I guess the drip would still be better than nothing at all.

|

| Thread: To etch or not to acid etch (primer paint) |

| 15/10/2017 01:00:17 |

Which scenarios is it good to use a first coat of acid etch primer as opposed to just using straight primer? Debating giving the new centec mill a paint job and have a tin of it I could use. |

| Thread: Embarking on a metal planer/shaper design+build |

| 14/10/2017 14:52:01 |

Posted by Ryan Farndon on 13/10/2017 21:33:03:

The cut size that has currently agreed on is 2mm depth by 2mm width on Aluminium (target series: 1000 and 2000).

I would change that to 2mm x 0.2mm. A single point cutting tool wouldn't be able to feed that hard. That is unless you want to think outside the box a little and make a planomill. https://youtu.be/R-b8PuuH3KU?t=15m8s Heres a video of a large shaper taking a 6.25x0.5mm cuts. The weight of the vice on that shaper will probably equal your final machine.

Also no one actually linked to a table top planer yet I think, so have a look at this tiny guy in action. https://www.youtube.com/watch?v=uasnYYJC9jQ |

| Thread: Centec, stuck milling arbour |

| 13/10/2017 21:49:21 |

Had tried doing a wedgeing action with some screwdrivers, looks like I gotta bite the bullet and make a proper tool. If I feel proper I might make something out of O1 and harden them. Might make a proper thread later, it's a weird mill. Vertical travel controlled by a gas valve knob leading to a rack and pinion. Might of screwed up and bought a production machine. The lever X feed makes me want to make a tool and cutter grinding attachment though. |

| 13/10/2017 15:28:53 |

| Have a new centec, arbour won't come out. Have stuck a brass rod down the spindle and applied considerable force via hammer and haven't budged it. Have liberally applied oil to the taper area. Are there hidden fasteners or something on the mill? Didn't come with a draw bar so not sure what to think. I have the pics in my "centec" album. On mobile do can't put the images directly in the post. |

| Thread: Denham Junior toolpost -options |

| 12/10/2017 15:40:43 |

I took mine from a 12.7mm distance to 20mm distance. That gives a 4mm toolpost base and room for a 16mm tool. Potentially overkill but I wanted to be able to have cheap second hand industrial insert tooling that could fit. I have a different topslide to yours, mine was very thick and somewhat primitive. Not currently near the lathe to measure how much meat is left though. |

| 12/10/2017 12:27:06 |

Might want to consider milling a bit off the top slide to allow for a floor on the 4 way. That was my method atleast.

|

| Thread: Brimsdown pillar drill reputation |

| 11/10/2017 22:39:54 |

Go to Albums near the top of the page and then select Add new photos. Once you have made an album with photos you can stick them in your post by clicking the camera symbol at the top of the post making box. |

| Thread: Embarking on a metal planer/shaper design+build |

| 11/10/2017 19:52:30 |

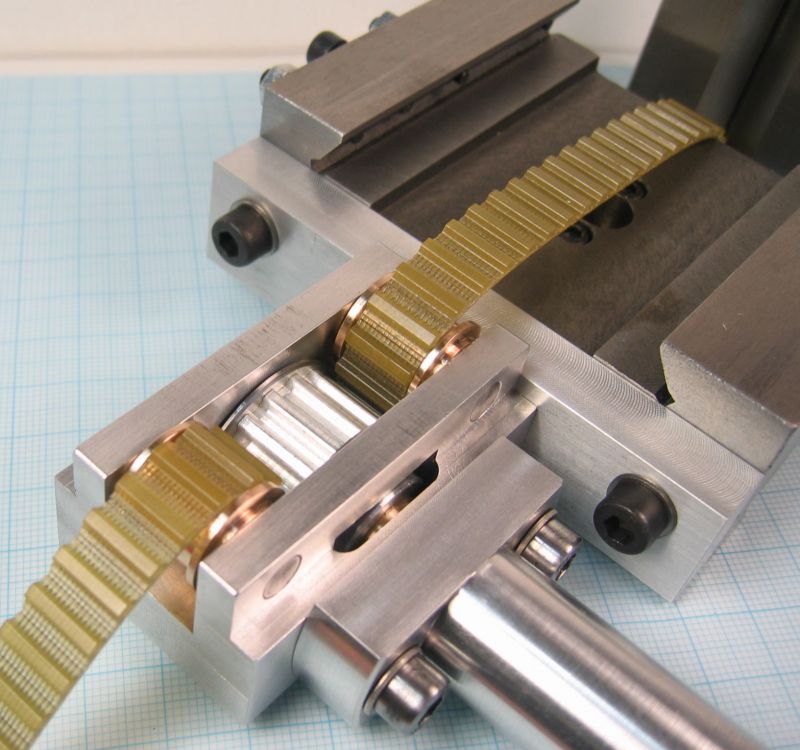

Most people are thinking Gingery because someone with a propane tank and a bunch of time can make it from nothing, however we are dealing with someone who I imagine has access to CNC lathes and VMCs. Re: some hints on planer construction http://metallmodellbau.de/MINI_BONELLE_II.php I would move the table using a timing belt as shown in the above link (thats for a small grinding machine). Gives fast, wear free motion. Ballscrew would be expensive, rack and pinion expensive-ish and an trapezoidal leadscrew too slow. On the input to the wheel put a medium (~200-300W for small machine, see how your budget goes) DC motor. Connect the DC motor to a H bridge and some inductance limit switches to tell it when to reverse. Use MGN linear rails to move the relatively fast and often moving table. Have the rails bolted to a chunky slab of steel, skimmed on a mill or surface ground would be best for accuracy. http://www.model-engineer.co.uk/forums/postings.asp?th=129363 <- Noci made a very nicely made automatic feed to his shaper as previously mentioned. You could do a lot worse than taking inspiration from his method. |

| Thread: Someone's bound to know what this faceplate fits. |

| 08/10/2017 14:55:47 |

Same thread as a Keighley lifts / Denham / Milnes type lathe. Only the early ones though, Mk2 have a 1.75" thread. |

| Thread: How to make a monochromatic light? |

| 08/10/2017 14:47:08 |

Could go for the 35W sodium bulb or a 7W array of lasers (based on lumen per watt). Think they will end up approx same cost/ £26 If I use yellow/amber LEDs I can get away with just £5 and have the sodium colour. Thats using 100 of the 5mm round LEDs. Don't know if the type you would see in say a spotlight would work as well. Edited By Rainbows on 08/10/2017 14:47:34 |

| 08/10/2017 12:36:23 |

I have a chance to buy some optical flats for pretty much no money. Seen some people on youtube use them and though I probably don't really need them it still looks like a cool thing to have.

Issue is no one appears to be selling monochromatic lights willy nilly and new ones are >£2000. Anyone know a way to cheaply bodge a monochromatic light source? |

| Thread: Dismantling abwood vice |

| 08/10/2017 12:17:17 |

Turns out there was just a massive amount of solidified brass swarf. Probably didn't do the nut any good by forcing the screw through via brute force but it worked/ |

| 06/10/2017 17:14:11 |

Got a new vice a bit ago. Someone rusty and with a significant case of drill pecks. Want to take it apart for a clean and refurbish.

Taken off the plate attaching the leadscrew to the moving jaw and screwed the leadscrew as far as it goes. Issue now is that it won't come out any further. Can turn it using more force but eventually it gives but won't have moved at all. Flipped the vice over and found 3 holes in the bottom. Can't make out a fastner at the bottom though.

Anyone got any hints on getting it apart? Its a 6" vice if thats important. |

| Thread: How to center ACME lead screw in the lathe |

| 04/10/2017 20:17:03 |

Use an indicator with a large foot so that it cant fall into the thread root. Make a ring with a bore to closely match the thread OD, turn OD and ID in same set up to guarantee concentricity. |

| Thread: Looking for an MT2 Milling Chuck. |

| 29/09/2017 18:03:54 |

The ER collets have a good range of squish. Eg: You could hold a 1/4" (6.35mm) endmill in a 7mm collet (works 6-7mm). Posilock needs a threaded shanked cutter to work. ER can take smooth or threaded shanks which allows carbide tools and cheaper cutters in general. Also get 1/2 price on arceruo ER vs Chronos Posilock which would give you a good selection of cutters for the difference. As a last thing you can use ER collets for workholding on the lathe as well. |

| Thread: Incinerating waste |

| 28/09/2017 13:42:15 |

Anyone know if there is a law against incinerating waste in your garden? Having issues with black bin capacity and googling it only turned up industrial and commercial rather than domestic scenarios. |

| Thread: Plans for a quill vertical head for the mill? |

| 26/09/2017 19:53:50 |

As seen recently on the classified my friend was on the look out for a small mill. Ended up finding a Centec 2 for £280 inc delivery. Gotta be said I am somewhat jealous its probably better than my Denbigh.

Issue is he would prefer a vertical mill and the milling heads are expensive and currently nowhere to be find. I get the vested interest here of having a milling machine to use in sheffield as well as a compensation package if I make him one. Fixed head would be easy, don't think I would have too many issues making one of them. Ideally though we want a quill head. Something like the centec head with its lever and fine feed would be perfect but I have no idea how they are made. Has anyone got a build log of making a vertical head? Or just a good clear diagram or exploded view of one. |

| Thread: My very own Quick Change toolpost |

| 24/09/2017 14:57:32 |

I would drill and ream holes for 2 dowel pins and make them what locates the dovetail. I wouldn't massively worry about the material between the hole and the dovetail, I don't think too much force would transfer through it. Not sure if the general concept is better or worse than the usual methods of toolpost design. I guess if you can't make cams too easily it makes sense though. |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in