Member postings for Graham Wharton

Here is a list of all the postings Graham Wharton has made in our forums. Click on a thread name to jump to the thread.

| Thread: Alarms and Diversions |

| 01/01/2014 16:38:32 |

Posted by MICHAEL WILLIAMS on 31/12/2013 09:22:24:

Everything difficult to get at . Everything difficult to remove . Lots of random hazzards .

Ahh briliant, I've had these in place for years. |

| Thread: Bearing Precision Class Identification |

| 01/01/2014 10:13:07 |

Thanks for the reply guys. Timken list the max tolerances for their taper roller bearings as follows Inner bore Class 4 +0.0005/-0.0000 Class 3 +0.0005/-0.0000 Outside Diameter Class 4 +0.0010/-0.0000 Class 3 +0.0005/-0.0000 Inner Ring Width Class 4 +0.0030/-0.0100 Class 3 +0.0030/-0.0100 Outer Ring Width Class 4 +0.0020/-0.0100 Class 3 +0.0020/-0.0100 Radial Runout Class 4 0.0020 Class 3 0.0003 Sounds as if these are absolute extremes, Youve all made me feel a bit better about the likely outcome if I was to fit standard precision bearings though. I did look at SKF but they don't do any that will fit. Prices are Timken RRP, which I believe get discounted by about 50% when they get to the shops. 2523-20024 £31.84 ex vat 2582-20024 £62.48 ex vat 1922-20024 £22.47 ex vat 1975-20024 £67.07 ex vat Ive sent some emails to some bearing distributors and am awaiting replies and actual prices. The bearings that are in the machine at the moment are actually in good condition. I removed them with a view to finding out their numbers, and then if they were 30/40 quid for the lot, then I would just put new ones back in. However if they are going to turn out to be 100 quid ish for the set, then i'll probably clean up, repack and refit the existing bearings.

|

| Thread: Restoring Beaver VBRP Mill |

| 31/12/2013 20:33:19 |

Nice work Paul. Look forward to seeing how it turns out. I hope to do a similar size refurb on an old beaver or bridgeport when I get more space. Just a comment about your plans to hook up to a 3 phase supply generated by an electronic inverter. I believe these can only be used to power a single motor at a time. The instruction manual in mine says to wire directly from inverter to single motor, and not via any switchgear at all. You might want to look into this before committing to any big inverter purchases. I think a rotary converter would be fine for multiple motors. Graham

|

| Thread: Bearing Precision Class Identification |

| 31/12/2013 19:56:03 |

According to the Timken catalogue, Normal precision Taper Rollers can have TIR of up to 2 thou just in the bearing itself whereas the precision grades start at 3 tenths TIR. I dont know about you, but i'd be a bit miffed if I just spent 100 quid on a set of standard precision bearings and ended up with 2 thou runout on the bearing itself. Graham

|

| 31/12/2013 19:34:20 |

Hi chaps, These bearings are from the horizontal spindle from a Tom Senior Junior mill that I am refurbishing. They are Timken Taper Roller Bearings Front - 2523/2582 Rear - 1922/1975 I'm trying to work out the precision class. Can anyone help from the photos, or know what would be fitted. Front Rear |

| Thread: Units of measure in Gear cutting |

| 15/12/2013 22:33:51 |

The numbers in the tables are for a 1DP cutter For other DP cutters, you must divide the number by the DP of the cutter you are making. e.g if you are making a 20DP cutter, and the value in the table is 4, then the measurement you need is 0.2" This is explained in more detail on the last page of the book. (Might have been nice to include a footnote on the relevant pages though) |

| Thread: What did you do today? (2013) |

| 08/12/2013 13:05:07 |

My metric tap and die drawer, some 0.9mm thick mild steel sheet, an angle grinder, a welder and one bored engineer on a sunday morning. Might not be the prettiest of welding, but I think you'll agree its functional. It certainly floats my OCD "things neatly in drawers" boat. |

| Thread: Is Abwood English or American |

| 19/10/2013 18:14:49 |

Just trying to work out whether the threads on an old Abwood 4inch milling vice are likely to be UNC or BSW. Its got 1/4, 5/16 and 3/8 threads on it, but UNC and BSW are the same pitch. I've tried winding in both UNC and BSW bolts, and I cant tell any difference. On one hand I'm thinking why bother getting it right if both fit, but then again my nut and bolt OCD will be off the scale if I don't use the right ones. TIA Graham

|

| Thread: Barrel Lap |

| 18/03/2013 17:25:09 |

Jason, that looks neat. Is there a taper on both the shaft and the inside of the expanding part so you get even expansion across the length of the lap? That was the only thing that put me off making my own, i.e the need to machine tapers. (I don't know why, but machining tapers is something that I shy away from (probably due to me not doing them so often)) |

| 18/03/2013 16:46:04 |

|

There are a couple for sale on ebay in the states. Might be a cheaper way to get one, assuming you need 1/8" or 5/32" that is! Graham

|

| 18/03/2013 16:41:42 |

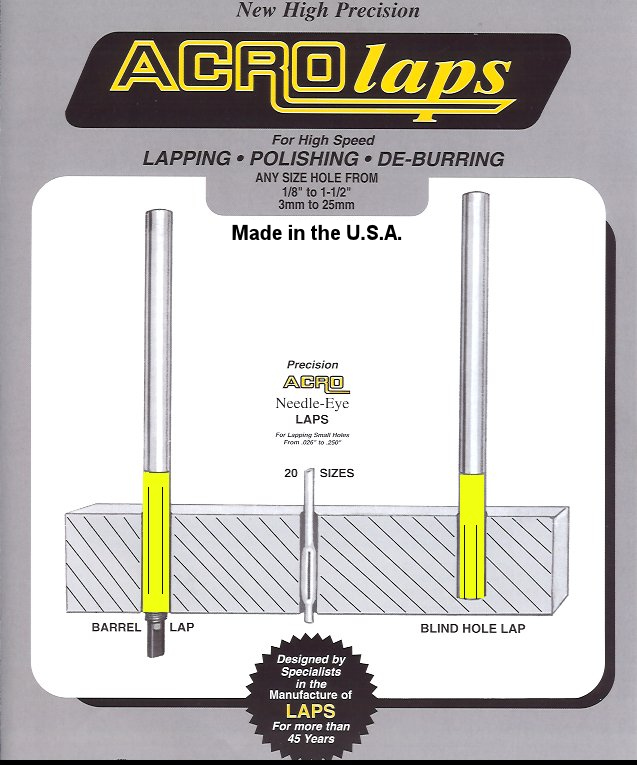

Springbok, I believe they are called Barrel laps, because they are shaped like barrels. They have nothing to do with guns. The acrolaps are a really nice design, and make finishing of a cylinder liner for diesels a pinch. You can see from the below picture, the barrel lap is for through holes and expands in the centre, forming a barrel shape as the tapered pin is screwed in. The blind hole lap, expands at one end when the tapered screw is fed in.

|

| 18/03/2013 15:37:29 |

I contacted the manufacturer of Acrolaps back in 2010 and they had no UK distributors back then. I ended up buying from the states and getting shipped. I bought from here I got a 10% online discount, and shipping to the UK was $14.95 for my order There was a minimum order quantity, but it was only in the region of 20USD i think. I bought 1x15/32 lap with 3 extra barrels and 1x1/2 lap with 3 extra barrels and the total, including delvery came to $41 I didnt get stung for any import duty or tax on this one and the package came in around 1 week. I believe I submitted the order with no shipping, they then calculated shipping, sent me invoice and charged the card I gave during the order. I dealt with Kristen, ([email protected]) who was very helpful. Hope this helps, if you dont find anyone in the UK stocking these. Graham

|

| Thread: Making a piano hinge bind and get stiffer |

| 03/03/2013 17:27:29 |

Ive given the loctite suggestion a go first as that involves pretty much no effort. If that doesnt do the trick, then I'll look into packing out the middle screws on the hinges to create distortion, then last resort, remove the pin from the hinge and do some selective pinching.

Les..... "Remember to squeeze at least one segment of EACH side of the hinge." <- on inspection of my attempt number one, i had indeed fallen at the first hurdle!!! Cheers guys. Graham

|

| 03/03/2013 14:54:22 |

Hi there, Does anyone have any ideas on how to make a piano hinge stiffer to operate. I have some polycarbonate sheets acting as chip guards on my mill which are hinged like doors on uprights using piano hinges. They swing wildly with the slightest breeze and vibration. I'd like to get it so I move the door into position and it stays reasonably where it is. Ive tried pinching the hinge with pliers in two places but that seems to have had little effect. Any genius ideas for me to try. Thanks Graham

|

| Thread: Updating a PC and software to Windows 8 |

| 22/01/2013 13:46:25 |

If you dont have a touch screen, and hate the tablet "metro" interface, there is a little program called "Start 8" and it basically turns off the "auto start in metro" and gives you a Windows 7 style start button and desktop back. It essentially reverts the look of the user interface back to Windows 7 looking. You can still run the metro tablet desktop, but I just find it easier. It costs a couple of pounds. I am not affiliated with that company. Thunderbird is a pretty good mail client, should feels miles ahead of Eudora if thats what you are used to. Have you checked the microsoft website to see whether a download exists for MS Visual C++ Redistributable installer exists for Windows 8? e.g **LINK** Check right down the bottom. There are links to many different versions that you can download that may be compatible.

Graham

|

| Thread: Clarkson 8mm Autolock S Type Collet Small |

| 19/12/2012 19:04:47 |

Ive had a saved search worldwide on ebay for about 8 months now, and nothing has ever triggered it. I think i'll just go hunt the 8mm shank cutter, and throw it if I find it (although I guess I can still use it in my ER32s ) If you look at the metric part numbers, the 6,10,12,16 are all sequential numbers, with the 8mm having a somewhat higher number, which would support Michaels thought about an update to the range. I am however more looking to satisfy my major tool OCD. I currently have Clarkson S Small 6mm 10mm 12mm 16mm 1/4" 3/8" 1/2" 5/8" Clarkson S Medium 1" Clarkson S Large 20mm 25mm 32mm 3/4" 1" 1.1/4" Does anyone else get tool OCD and collect "Full sets!!!!" regardless of need? (turns out to be quite an expensive thing to do) |

| 18/12/2012 19:41:40 |

I too thought they never existed too however I recently came across a cutter in my garage (which I can no longer remember or find....typical) that was an 8mm threaded shank. http://www.cromwell.co.uk/CTL0627010Y Clarkson part number 40M92 A skip through clarkson and dormer cutter catalogues and I cant find any tooling that is 8mm threaded shank. |

| 18/12/2012 19:15:31 |

Hello all, Quick one.....Has anyone ever come across a Clarkson Small SType Autolock Collet in 8mm. They appear to be as rare as rocking horse sh*t. Thanks Graham

|

| Thread: Swarf vaccum cleaner |

| 14/12/2012 21:51:46 |

I'll stick a vote in the air for a Numatic Charles. Its the big daddy of the henry. I picked mine up on ebay for £25.00 One point. Where the hose enters the body of the hoover, there is a large plastic clip inside which secures the hose in place. This has some poorly positioned plastic pieces that catch oversized curls of swarf and makes it block reasonably easy. I removed this clip to stop the blocking. This had the unwanted effect of allowing the hose to be freely pulled away from the unit when you try to drag the hoover by the hose (not good...) but if you turn the hoover on before dragging, the suction is easily enough to keep the hose in place while you pull it around. Suction is brilliant on it. No worries at all from a power department. It sucks just as hard as my Dyson in the house. I removed all bags and just left the material cover that forms part of the lid, this was fine for filtering garage dust, but does get a bit dirty with greasy swarf and required a good banging against the side of the bin when emptying. The hoover also came with an alternative insert with integrated ball, that allows you to use the hoover for sucking liquids too. Can't grumble I suppose. Graham

|

| Thread: Note to self. Dont put thinners into Ultrasonic cleaner...... |

| 14/07/2012 21:57:37 |

This one had a stainless bath, but the buildup of thinners fumes with the plastic lid shut was just too much for it. This was a 30 quid ebay special so I'm not too fussed. Experience of using it prior to the big melt was pretty poor. If I put in a dirty tap that I wanted to clean, you could see spots of dirt coming off the tap, but it came out only slightly cleaner than it went in. There were still bits of dirt left on the item, that could easily be removed with slight finger pressure. So, what are other peoples cleaning experiences with US baths. How much do you need to spend until you get decent cleaning effort. What sort of results are people getting. Am I expecting too much from US cleaning. What are the key specifications to look out for. What power rating, heated tank a requirement? Thanks. Edited By Graham Wharton on 14/07/2012 21:58:05 |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in