Capco surface grinder manuals

| Colin Seggie | 12/04/2014 09:06:28 |

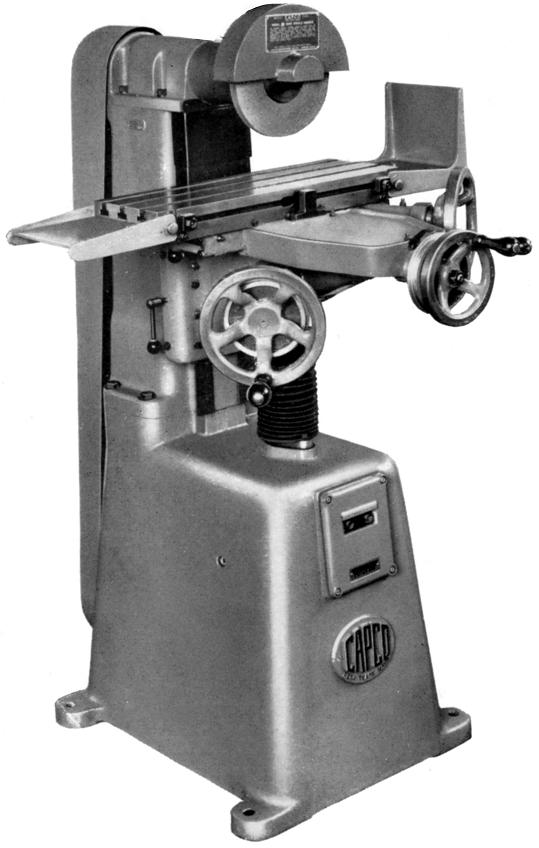

| 25 forum posts | Hi all, I have just bought a capco surface grinder and while there is a little intfo on t'net I can't find any manuals. Does any one have manuals. I am not sure what manuals are available but normally it is something like Installation and maintenance, operation and parts manuals. Also any other info on attachments etc would be welcome. It seems from lathes.co.uk it is a MK2 model 2

Thanks Alastair Edited By Colin Seggie on 12/04/2014 09:07:16 Edited By Colin Seggie on 12/04/2014 09:09:54 |

| Colin Seggie | 12/04/2014 11:37:51 |

| 25 forum posts | Cheers John, You are completely correct I know very little about this type of machine, thanks for the "heads-up" I would have found that out the hard way! As it turns out this one comes with a mag chuck so I assume that it is correct for the machine. I believe the travel is 14" x 6" but I don't know the chuck size. This exactly the kind of info I need thanks. Alastair |

| Oompa Lumpa | 12/04/2014 13:32:43 |

| 888 forum posts 36 photos | A couple of months ago I had a chance to buy a machine very similar to this one and foolishly I passed on it thinking I couldn't accommodate it. I really should have bought it. I am very envious. I will be getting one sooner rather than later as I am having to borrow a friends more and more. graham. |

| Nobby | 12/04/2014 15:21:37 |

587 forum posts 113 photos | Hi |

| Robbo | 14/04/2014 20:43:45 |

| 1504 forum posts 142 photos | Alastair, I doubt you will find a Manual as such, but they are not difficult to operate. John has pointed out the need to dress the mag chuck surface on the machine from time to time. Eclipse reckon that the main reason for loss of holding power is failure to dress the table, so the surface is not smooth. Obviously this is done with the chuck "off". Like my old Pallas grinder, Capco is very open. While these are excellent little machines, they are also very good at throwing filth in all directions. Recommend you think ahead on this and try to provide some shielding to contain this. The little guard at the end of the table does very little, but I have found that the biggest flat magnet available, fixed to the guard and covered with a polythene bag will catch a lot of the metallic dust, the bag is then reversed off and contains all the gunge cleanly. The ideal would be some sort of extractor system, but whilst I have thought a lot about this have yet to get around to it. Surrounding the machine with a sort of "tent" of polythene will keep a lot of the dust in one place, likewise think about the location of the grinder. If you can back it into a corner then it's easier to box in and can have a little roof of its own. Believe me, the muck does get everywhere. If you have other machines near it then cover them up whilst grinding.

Phil |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in