Member postings for Colin Seggie

Here is a list of all the postings Colin Seggie has made in our forums. Click on a thread name to jump to the thread.

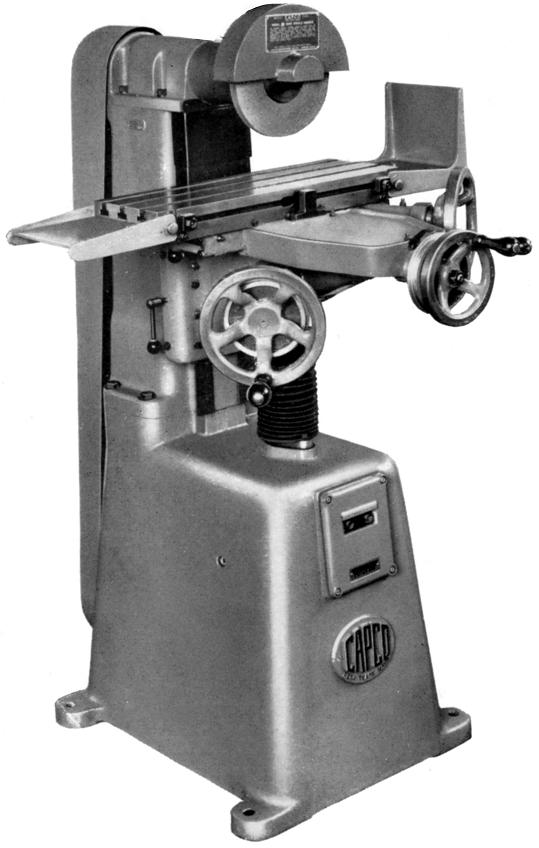

| Thread: Capco surface grinder manuals |

| 12/04/2014 11:37:51 |

Cheers John, You are completely correct I know very little about this type of machine, thanks for the "heads-up" I would have found that out the hard way! As it turns out this one comes with a mag chuck so I assume that it is correct for the machine. I believe the travel is 14" x 6" but I don't know the chuck size. This exactly the kind of info I need thanks. Alastair |

| 12/04/2014 09:06:28 |

Hi all, I have just bought a capco surface grinder and while there is a little intfo on t'net I can't find any manuals. Does any one have manuals. I am not sure what manuals are available but normally it is something like Installation and maintenance, operation and parts manuals. Also any other info on attachments etc would be welcome. It seems from lathes.co.uk it is a MK2 model 2

Thanks Alastair Edited By Colin Seggie on 12/04/2014 09:07:16 Edited By Colin Seggie on 12/04/2014 09:09:54 |

| Thread: Way grinding firms in Scotland or North east |

| 28/03/2014 10:56:28 |

Gents Thanks for the replies and lively debate! I will let you know how I get on. Alastair |

| 08/03/2014 22:52:58 |

Thanks John I got a number form that.

Alastair |

| 06/03/2014 18:58:05 |

Brian I will give them a call. Still looks like there is nothing or very little in Scotland which is a pity given its engineering heritage! Alastair |

| 06/03/2014 18:55:44 |

Peter, would that possibly be blue diamond? They don't mention anything about having machining facilities in house on the Website. Do you know if they do slide way grinding in house or if it is contracted out. Alastair |

| 06/03/2014 15:56:58 |

Dear all, I have searched and searched and cant find any one remotely local to re grind a lathe bed and a few other odds and ends. Does any one know of any one say north of York? Alastair |

| Thread: Adjusting the ML7 spindle bearings (New bronze version) |

| 13/11/2013 09:33:05 |

Hi All I seem to be having some issues. I've been scraping for about 17 hours now and I have good contact on the bottom bearings, and the tops are coming along. Now I ve removed a lot of material, far more than i was expecting, since myford say that the spindles and bearings & shaft are paired? My issue is that I am getting lots of side to side play about 2 thou. I also note that at the same time the top bearing housing moves about the same, which does not seem right. Even when I torque the bolts up tight. I've tried to scrape more on the bottom to in effect drop the shaft down a bit and get the V block effect Blowlamp alluded to Can any one shed any light? Alastair |

| Thread: ML7 / Super 7 tailstock |

| 10/11/2013 09:51:41 |

Thanks guys, that is great news I will keep on the look out for one. Alastair |

| 09/11/2013 09:11:16 |

Does that mean that a super 7 tail stock will also fit a ML7?

Alastair |

| Thread: Extra Special Subscription Gift for Model Engineers’ Workshop |

| 05/11/2013 09:58:11 |

Posted by JasonB on 04/11/2013 18:23:55:

One other query Existing subscribers have been able to view the online digital archive even if only paying for the printed version. If that existing subscriber cancels their sub and takes out a new "Print Only" to get the gift will they then loose that access to the digital archive, taking another £11 of the true value of the gift. J From thew Archive Page, "We will also be honouring the access granted to Print Subscribers as part of the 'Complete Package' Subscription. This access will only be available until your subscription expires, and access to Print Subscribers will be totally withdrawn from July 2014." Alastair |

| 31/10/2013 08:09:51 |

I am also keen to know about direct debit customers. Do we need to renew? I think you will get high demand for this! |

| Thread: Adjusting the ML7 spindle bearings (New bronze version) |

| 30/10/2013 19:59:57 |

Andrew, I am up for the challenge I love doing new things, in fact that is my biggest problem i never master anything! Mike would those not be too big? Ian and andrew, I have never seen a scraper up close so I don't think I would be able to make one even if I had the file to make it out of I think in the first instance I am going to buy one. I have a marine engineer friend who has scraped bearings before so as soon as I get the scrapers he is going to come round and see if it comes back to him after 25 odd years. Alastair |

| 29/10/2013 12:09:31 |

Just a quick question on bearing scraper size what size do I need the front bearing is fairly large but the rear bearing is much smaller. So I am supposing you need a fairly small scraper?...or have I got this wrong? Anyone able to give me rough dimensions of the scraper needed |

| 27/10/2013 11:48:03 |

Andrew its the going too far that worries me! especially as I have never done anything like this before. Thanks for the tip I will keep an eye out for that! Alastair |

| 27/10/2013 10:21:33 |

Hi all thanks for the responses it really does help guide me. Martin thanks for all the info I am now on the hunt for a scraper! Ian - I did a running In process slow at first then slowly went up to full speed with 2x the normal amount of oil over about 2 days but it is only at the higher speeds that the bearing starts to heat up. I think that I need to look at the contact areas like Martin suggests just need the tools. Alastair

|

| 26/10/2013 23:46:44 |

Martin, Thanks for taking the time to explain that. It is aprieciated. I understand most of what you have explained needs to be done. I will have a look for bearing scraping videos before having a go. I think there was one on youtube . The only thing that I am still not sure about is what am I aiming for play wise and how is that best tested? i.e. what do i do to test and when do I stop and think well that is it done. Sorry for the dumb questions but this is all very new to me. Alastair

Edited By Colin Seggie on 26/10/2013 23:50:36 |

| 26/10/2013 18:19:55 |

Martin could you elaborate please. The new spindle comes with new Bronze bearings. Are you saying I need to scrape these even thought they are new? How is that done and to what tolerance? Or are you talking about martins Issue? Alastair |

| 26/10/2013 16:45:46 |

Hi I am look for some help with adjusting the spindle bearings on my ML7. A little history: I bought a ML7 a few yeas ago and I have been fixing bits and pieces over time. The spindle had some bad dings on the nose and internal scratches so I decided to swap it out for a new one. After remortgaging the house to pay for the new spindle it finally arrived. The first issue I had was that once installed it locked solid I had not even torqued up the bolts!! I was expecting to have to take a few layers off the Shims. Any way 3 sheets of post -it notes and I was good to go.....well it turned. I did not understand the criticality of getting the bearings adjusted just right. so Fast forward about 11 months and I was having big issues with turning a 100mm long 10mm shaft. without a taper. It would be right at one end but not at the other. So I set about trying to find the source of the issue. I leveled the bed to within a gnats. I could then adjust the back foot to get it to turn parallel but then the bed was skew, not level and most of all not co-planar. I felt that I was twisting the bed to fix another issue. Eventually I got a MT2 test bar, re-levelled the bed and ran a dial along the test bar in various rotational positionsthe results were all over the place..... that was when I realised two things 1) I needed to get the bearings adjusted first and 2) the lathe needed a thorough clean. The lathe is now clean and I started adjusting the bearings.....well I think I am adjusting the bearings correctly but but I am not sure. So here is what I have done. I got a 2"x1" batton about 1m in length and another block to act as a fulcrum and put a moderate amount of force in the upward direction, I had installed a DTI which reads to 0.005mm (well those are the smallest divisions) the spindle moved 0.095mm so almost 4 thou. Next I removed all but one of the pieces of paper (there were 3 at 0.06mm (2 thou) each) from the Front bearing and tightened it up....it locked. I kept adding equal amounts of Ali foil shims (0.015mm) to each side until the spindle was free to run and there was about 0.01mm (0.0004" ) play using the 2x1. I repeated this on the rear using the drive belt to lift the back end. After Tightening up the slop in the spindle bearings I used the test bar just in the spindle (no tail stock ) and found that the head stock was out about 0.07mm (3 thou) out at the end of the test bar roughly 220mm from the end of spindle nose. I shimmed the head stock to pull it straight and was berry chuffed with my self . However, pride comes before a fall and....all was well until reassembled and I moved the spindle speed up to maximum rpm the front bearing stayed cool the rear got warm. I ran the lathe for 30 min and the temperature stabilised at 32C for the rear and about 26 for the front. Ambient in the garage is about 18 today. Ok so now the questions:

Thanks for reading all of that any help would be most welcome. Alastair Edited By Colin Seggie on 26/10/2013 17:00:42 Edited By Colin Seggie on 26/10/2013 17:01:11 |

| Thread: Bridgeport mill dual dial help needed please |

| 19/10/2013 00:28:12 |

Steve just replied to your pm. Alastair |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in