Boley 5lz collets

| Putney man | 14/04/2012 09:09:11 |

| 18 forum posts | I have a Boley 5lz - actually its still at Bede tools who I bought it off, but I hope to move it soon. The collet size is described as "a 12 size 4", I cannot actually find if that is still made - anyone able to shed any light on this - is there an alternative standard? |

| Philip Burman | 17/04/2012 21:51:49 |

| 16 forum posts | I also have a Boley 5LZ. The collets are 358E, also known as W23. The cheapest source in Europe is here: http://chinamarkt.de/html/product_info.php?products_id=1314&osCsid=429173d54e20c4e5816d92367bbd2f79 I bought a number of them a year a go. They are Chinese but very precise. However 2 or 3 had incompletely formed threads. It was easy enough to mount them in a 4 jaw independent chuck and run the lightest of skims to clean up the thread. Phil |

| Putney man | 18/04/2012 12:13:04 |

| 18 forum posts | Thanks - this is really helpful. BTW do you have mains 3 phase to your 2 speed motor, or have you rigged up an inverter or converter to power it up? Edited By Putney man on 18/04/2012 12:13:28 Edited By Putney man on 18/04/2012 12:13:49 |

| Philip Burman | 18/04/2012 14:22:25 |

| 16 forum posts | I was lucky with the house, I had 400V 3 phase at the meter so I ran a cable into my workshop/garage and, as the lathe was 230V 3 phase (it's not dual voltage) I have a 5kw three phase transformer to step it down. The garage is also insulated and has under-floor heating, which makes things very cosy. I did some reading on phase converters and even bought the parts to build one (before I bought the house). What voltage is your 2 speed motor.

Phil |

| Putney man | 19/04/2012 07:52:31 |

| 18 forum posts | Its 400v 3 phase - a UK spec motor. I believe i can run it off a single 240 - 440 3 phase digital inverter - but they are £1000. Its still cheaper than me getting 3 phase mains installed. I have also aquired a Hardinge - same problem. Are you pleased with the 5LZ? Have you had any issues with the reverse gear? |

| Philip Burman | 19/04/2012 09:02:26 |

| 16 forum posts | I think you need to look into the issue of the digital phase converter very carefully. You will lose lots of functionality with a DFC connected directly to the motor. One of the key lathe functions is the "instant" 4 times speed reverse when threading. This makes threading without disengaging the half nuts a piece of cake. For this to work you need the electric clutches and brake to be working together with the electric switching. I think you should consider a rotary phase converter as your base case. I've just had a thought that if your machine is for the UK market maybe it's imperial and you have a threading dial. Some photos would be interesting to see. I am very pleased with mine. I have zero experience with machines of this quality but it is all I expected and some. It's extremely rigid and precise. I attempted to test the brochure claim that it is impossible to get it to chatter. I tried the maximum DOC (16mm) in mild steel that my carbide cutter would allow. It passed the test like I was taking a finishing cut. Also when you dial in a DOC that's what comes off every time, no more no less. I'm not sure what you mean by reverse gear. I did have some noise issues with the 4 times speed reduction gear (when in reverse) but that was largely me being over sensitive. I've given up trying to eliminate it (for the moment). The spindle oilers are a pain to set to the right rate as there is no feedback on the actual "drip rate". The as supplied QCTP is limited in functionality as the bottom edge of the tool holders sit lower than the top face of the top-slide. This prevents rotating the tool post to achieve the desired angle. This means you need lots of extra tool holders, which of course are none existent. I replaced the whole thing with a Multifix type A. Because of the relatively high height of the top of the cross-slide the Multifix is limited to 12mm square cutting tools if you want to retain the 40 position capabiity. You can of course mount 20mm square cutters directly on the cross-slide when more umpf is needed. I also fitted a 2 axis Newall DRO.

Phil |

| Philip Burman | 30/11/2012 19:20:09 |

| 16 forum posts | Hi Putney man, how is your Boley 5LZ going.

Phil |

| RK 2014 | 10/01/2014 15:38:10 |

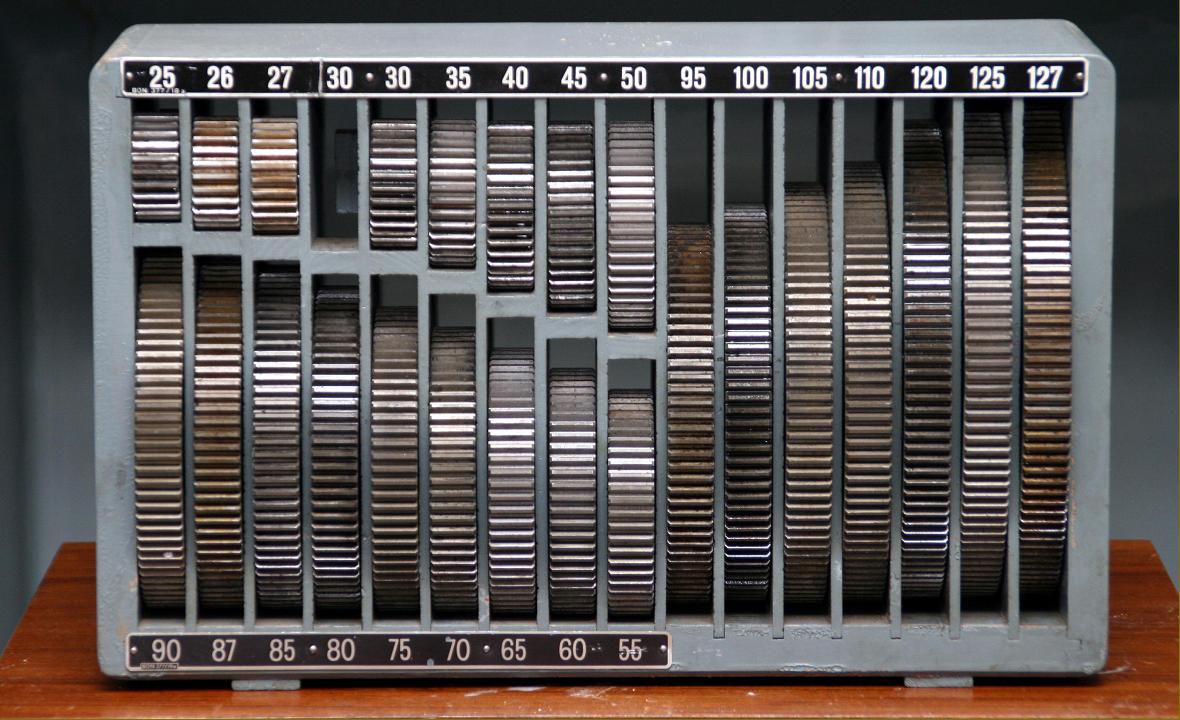

| 6 forum posts 22 photos | Hi guys, I also have Boley 5LZ, which I bought recently and I am restoring it now. Could someone of you help me please to get the main dimensions of the tumpler gear, which is misssing on my lathe? I intend to manufacture a replacement of it. Also a photo could be also helpful. Thank you, Roman

|

| Michael Smith 15 | 25/01/2014 10:09:25 |

| 28 forum posts | I have recently acquired the Boley5LZ that was at Bede tools .It is a metric machine and the headstock is 5 morse taper .I assume that the a12 size 4 collets fitted directly into the headstock .In the only literature i can find there is no mention of a morse taper spindle The chucks are flange mounted and located by a short taper .I would be interested in hearing from anyone else who ones one of these lathes. Mike |

| Philip Burman | 29/01/2014 13:39:39 |

| 16 forum posts | Hi Mike, seem to be lots of people turning up with 5LZ's. We will soon out number the Myford 7's. Well maybe not this week. Yes the a12 collet, better known as 358E, fits directly into the spindle, the is no adaptor. Out of curiosity what does the end of your drawbar look like? Phil |

| Philip Burman | 29/01/2014 14:33:38 |

| 16 forum posts | Posted by RK 2014 on 10/01/2014 15:38:10:

Hi guys, I also have Boley 5LZ, which I bought recently and I am restoring it now. Could someone of you help me please to get the main dimensions of the tumpler gear, which is misssing on my lathe? I intend to manufacture a replacement of it. Also a photo could be also helpful. Thank you, Roman

Hi Roman, do you intend to make an identical copy or something that is just functional. Phil |

| RK 2014 | 30/01/2014 15:38:33 |

| 6 forum posts 22 photos | Hi Phil, my idea is to make a functional replacement if the original tumpler gear, not identical copy as for it it is a casting necessary. It should be a case consisted of be two side steel panels holding the bearings of the plugs of the gearwheels. I can perform milling, turning, welding but not casting. Could you make a photo of the tumpler gear of your Boley and send it to me via e-mail ([email protected]), please? Thanks, |

| Philip Burman | 31/01/2014 00:44:09 |

| 16 forum posts | Hi Roman, I'll have a go on Saturday. Phil |

| Philip Burman | 31/01/2014 10:12:03 |

| 16 forum posts | Hi Roman, Email sent. It's 21mb. If it's too large I will send it as several mails if you let me know you maximum file size. Phil |

| RK 2014 | 31/01/2014 11:21:12 |

| 6 forum posts 22 photos | Hi Phil, hi Mike, thank you both for your help and for the photos of the missing tumbler gear! I believe it will be possible to fabricate a replacement. Roman |

| Robert Söderström | 17/11/2018 17:54:16 |

| 6 forum posts | Hi all, I also found a 5LZ with missing tumbler gears today, would someone be able to send me the images as well? Roman, did you manage to construct a new tumbler? Any pictures or plans of that? |

| Neil Wyatt | 17/11/2018 18:55:02 |

19226 forum posts 749 photos 86 articles | This is a rather old thread, take a look here: Well I'm glad I read this thread, it led me to this fine idea, which I am sure to copy!

Edited By Neil Wyatt on 17/11/2018 18:56:15 |

| Michael Smith 15 | 17/11/2018 20:06:39 |

| 28 forum posts | I still have my Boley 5LZ and use it regularly mainly for screw cutting ,they are very fine lathes but the headstock bearings require careful management . I have never managed to find any spares . There was one on Ebay recently I think it was a capstan version . It was in poor condition and did not sell ,it was far too expensive It might be worth looking at Leinen jathes . The L4Z shares some common parts Regards Mike |

| RK 2014 | 05/12/2018 14:10:18 |

| 6 forum posts 22 photos | Hi Robert, yes, I have few pictures of the missing tumbler gears which I have machined. Describe more your situation and needs, maybe I could help you. It is still in progress, once I will complete it I will share more pictures. Now two examples at least. |

| Robert Söderström | 05/12/2018 14:47:57 |

| 6 forum posts | Wow, have got a new housing cast by a foundry? I am completely missing the tumbler arrangement (and gear bracket)on my lathe,collected it on friday, and although I searched high and low and found a lot of small pieces I could not find those parts Looking for all info I can get on the part. Probably not going to cast a new housing, rather build it up in simpler manner with flat stock and standoffs etc. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

I am very interested in any plans or info regarding the construction of it, I am guessing it consists of three gears? Gear connected to output shaft on center of rotation? Gears are the same module as change gears I assume?

I am very interested in any plans or info regarding the construction of it, I am guessing it consists of three gears? Gear connected to output shaft on center of rotation? Gears are the same module as change gears I assume?

Register

Register Log-in

Log-in