Turning a taper spindle collet

Turning a taper spindle plug collet own its own lathe

| John McNamara | 13/11/2011 05:07:25 |

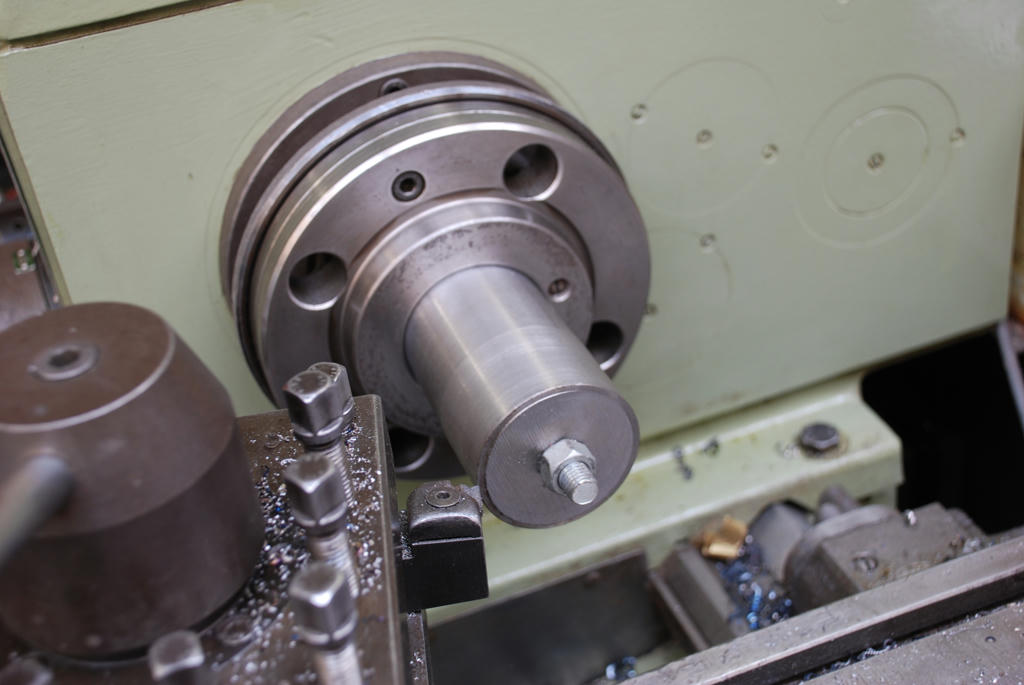

1377 forum posts 133 photos | Hi All Turning a taper spindle collet on its own lathe. This may have been posted before although I have not seen a post recently. I needed to make a MT3 and NT40 plug collet to fit directly in the spindle of the lathe. So a piece of stock was selected that was long enough to make the two with a 15mm extra allowance in case the taper did not fit first time and to allow for cutting them apart and facing The plug is about 65mm diameter at the widest point. The following cutting sequence was used. After measuring the taper with a protractor I set the top slide to match the taper. Then I mounted the three jaw chuck and I skimmed the diameter to remove the scale then bored a Half inch hole half way through from the tailstock then reversed the work piece and bored from the other end and creating a through hole, as it happens it was fairly true leaving a clearance hole for a 12mm all thread rod that would be used later to clamp the collet. next both ends of the piece were faced. Then after rechecking the material holding tight I made the first taper cut. Leaving the piece in the chuck I removed the chuck and tried the taper cut using a little marking blue. It was a little out so I nudged the top slide and reinstalled the chuck made another cut and tried again. This time it was (about) right. "That L Do" ! (something I do not often say)..... I removed the piece from the chuck and removed the chuck. Face: Continued next post..... Edited By John McNamara on 13/11/2011 05:12:02 |

| John McNamara | 13/11/2011 05:26:40 |

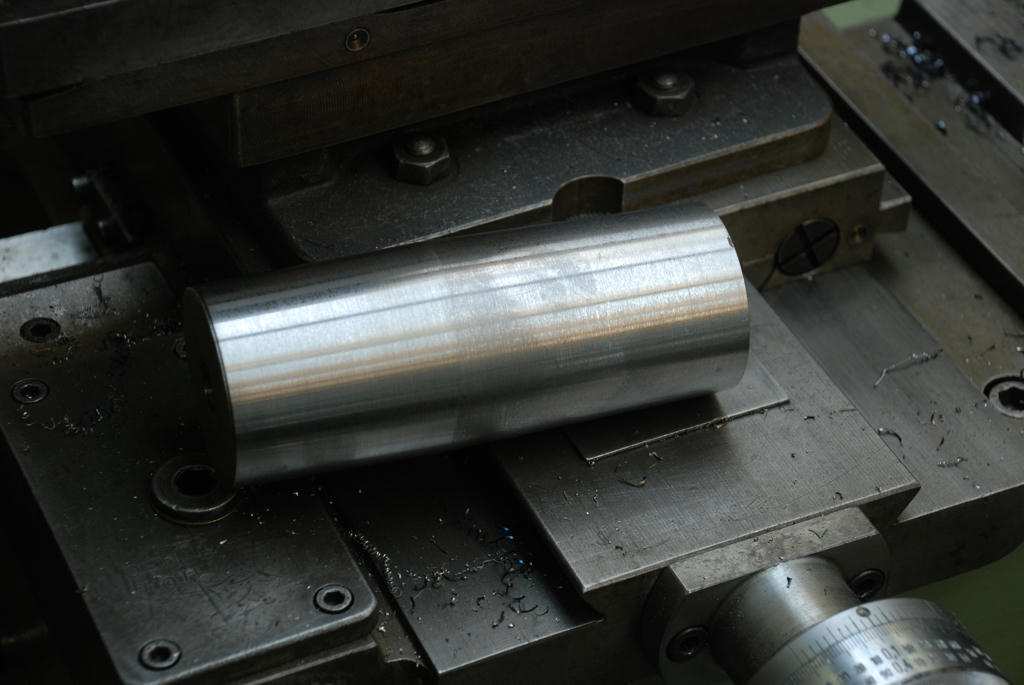

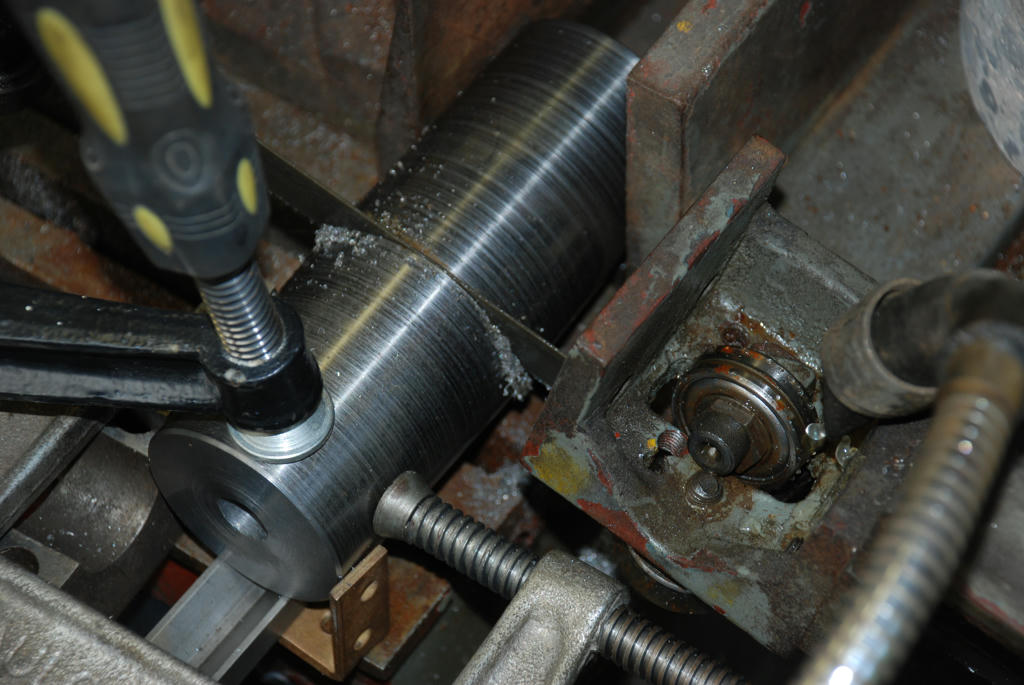

1377 forum posts 133 photos | Continued from previous post........ From that point on I would hold the piece in position with the threaded rod only. I installed the piece in the spindle clamped it with the all thread drawbar and turned the other straight end. It was then a simple matter of adjusting the taper with the top slide angle until a perfect fit was obtained I used marking blue to check the fit. No more trying to juggle a heavy 8 inch chuck, Using the taper alone guarantees perfect concentricity. It also saves a lot of time to make two at once. To assist removing the collet I put a nut behind it to enable it to be driven out using the all thread rod as a driver once completed the piece was cut in half using the bandsaw and the pieces refaced and bored MT3 and INT40 as required. The fit was more than enough to hold the piece in position for facing and boring. I just tapped it in position with a plastic mallet to seat it. For extra precision I marked the collet to index a known point (a small screw) on the spindle. Chuck no longer required

Second taper Ready to cut in two

Cut on the bandsaw (A fiddly set up it was hard to grip)

Ready to face and bore as required Cheers John Edited By John McNamara on 13/11/2011 05:41:03 |

| Richard Parsons | 13/11/2011 08:57:50 |

645 forum posts 33 photos | John next time set your compound slide using a DTI. If you are going to a male taper use the rear of the taper in the Headstock. This will give you a good taper. If you have a taper which is a bit ‘wobbly’ then machine away the centre of the taper. You will get a good fit. Regards Dick |

| John McNamara | 13/11/2011 10:14:45 |

1377 forum posts 133 photos | Agree Richard

A good fit but not a perfect fit. There is the chance of a slight error due to the cut line being slightly different from the line measured on the taper by the indicator. Unless the match is perfect two different tapers will result, Marking blue and trial cuts will yield a very close to perfect result.

It was easy to turn the work end for end and make tiny adjustments to the top slide. without having to manage a heavy chuck hanging on the end of the work. this is an industrial lathe, the chuck is 200mm diameter and weighs about 25 kg on its DIN back plate. It is almost impossible to "feel" that wobble with a heavy weight (Chuck) hanging on the end of it.

Making a pair makes the job easy, in this case I wanted two anyway.

The process would work for many different types of collets even very small ones. The advantage being that you are "fitting" them to their holder, then boring them in position. You do not have to stop at 2 you could cycle a dozen work pieces or more if needed. all perfectly fitted and bored in situ.

Cheers

John

Edited By John McNamara on 13/11/2011 10:20:20 |

| Andy taylor 2 | 04/08/2020 14:53:47 |

| 23 forum posts 4 photos | I realise this is a ancient thread but I am in need of creating some tapers I can use for tools on a small but very very rigid Taylor milling machine. What would the process be to create these please??

|

| Emgee | 04/08/2020 15:43:33 |

| 2610 forum posts 312 photos | Is the Taylor a horizontal mill with an MT3 spindle ? Emgee

|

| Andy taylor 2 | 04/08/2020 16:02:09 |

| 23 forum posts 4 photos | Posted by Emgee on 04/08/2020 15:43:33:

Is the Taylor a horizontal mill with an MT3 spindle ? Emgee

No mate its a vertical with a spurious non standard taper.

Edited By Andy taylor 2 on 04/08/2020 16:04:09 |

| Martin Connelly | 05/08/2020 20:39:28 |

2549 forum posts 235 photos | The link to lathes.co.uk says the taper is 23 degrees. I don't know if the spindle is bored for a draw bar. If it is then making an adaptor to use ER collets may be an option. Martin C |

| Andy taylor 2 | 05/08/2020 22:23:51 |

| 23 forum posts 4 photos | Posted by Martin Connelly on 05/08/2020 20:39:28:

The link to lathes.co.uk says the taper is 23 degrees. I don't know if the spindle is bored for a draw bar. If it is then making an adaptor to use ER collets may be an option. Martin C yes it does have a draw bar fitted. Its a very solid mill but I had a bridge port complate with tooling come up so I stopped worying about it. It reminded me when I read the thread about turning tapers. lol |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in