Pillartool

| Redpiperbob | 01/01/2010 16:40:50 |

92 forum posts 41 photos | Hello all

Could someone help me out please. I am just starting to build the G H Thomas Pilllartool. In the book Workshop techniques he states that the brass clamp pads should be parted off at 1.5" and yet the longest in the plans is 3/4"

Am I missing something or should I just past off at a tad over 3/4" and 11/16". It seems a bit wasteful of the brass. (Thats my Scrooge side coming out.).

Any help will be gratefully appreciated.

Bob |

| mgj | 01/01/2010 17:29:29 |

| 1017 forum posts 14 photos | I dont know the UPT, and whether you are working form plans or his book. So I apologise for Grannies in advance. Having built his VDH, the procedure for the clamps is as follows. 1. Turn the brass clamps to long size - see drawing for depth of hole . 2 Mark and drill the clamp holes. 3 Insert clamp blanks and lock down - drawing will show a screw hole between the pair of clamps,which is later blocked off for pulling a locking bar down - make from scrap. Or use a g cramp(s) if that suits. 4. Then bore the hole with clamps installed - you will take out the 1/2 moons in the clamps and have them all to size in one move. 5 Extract clamps, part off halves to length and insert counterbores and screw threads in appropriate halves. 6. Centre pop for identification because the clamps are "holed". (Like only fit that hole) DON'T try to do the bore first and then judge the cutouts in the clamps because you will never get it right, or in the right place. GHT's way you have a perfect fit, and a guarantee that all will line up when a clamp is bottomed in its hole. Edited By meyrick griffith-jones on 01/01/2010 17:30:40 Edited By meyrick griffith-jones on 01/01/2010 17:32:22 |

| Redpiperbob | 01/01/2010 18:37:50 |

92 forum posts 41 photos | Hi Meyrick

Thanks for the resonse I also have built the VDH but the pads on the pillartool are different as they only go half way thourgh the arm and base castingsthe depth of the counterbore to take the pads is 3/4" and 11/16" so I thought if I make them that size and when I have drilled the bores I can take them back out and then file a small amount of the bottom of the pads to make them grip the shafts that run though the bores. I can scan the pics but I dont think I should put them on the site (Copyright).

Bob |

| mgj | 01/01/2010 19:41:45 |

| 1017 forum posts 14 photos | Bob - I do apologise. The only comment I could fairly make is to say the GHT wasn't known for errors on his drawings. Having said that, looking at Dividing and Graduating (out of print now - I think its been incorporated into a bigger volume) there are drawings of part of a UPT showing the clamps on the inboard side of the column and staking head. Using I imagine the VDH type. of clamp. However, the photo shows a UPT with the clamp bosses on the outside, using just a split in the bracket. So perhaps you pays your money and..... depending on which castings you have? |

| John Haine | 01/01/2010 20:23:51 |

| 5563 forum posts 322 photos | When I do cotters I make both halves separate (for a split cotter) and clamp then in their bore with a thin washer in between, then bore the main hole for the thing they're clamping. Then you don't have to part the cotters, just remove the washer. For a single cotter put the washer at the bottom of the hole. |

| Redpiperbob | 02/01/2010 08:18:18 |

92 forum posts 41 photos | Hi All

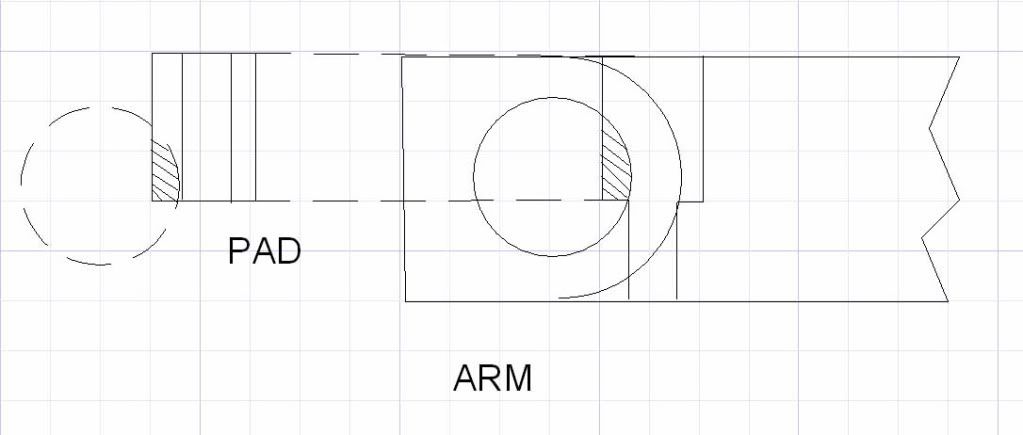

Thanks for the replies I thought I would show you the way GHT has draw the pads in his Workshop Techniques book.

one piture is woth a thousand words. I hope this expliains better what I mean

Thanks Bob |

| David Clark 1 | 02/01/2010 10:14:39 |

3357 forum posts 112 photos 10 articles | Hi There

In the pillar tool book the sizes are 11/16 and 3/4in. long.

You machine them with the bores then remove them and turn 1/4in. off the length.

I would use 1/4 spacers and 7/16 and 1/2 in. long slugs then throw the 1/4 ones away.

regards david

Edited By David Clark 1 on 02/01/2010 10:15:32 |

| Redpiperbob | 02/01/2010 10:22:13 |

92 forum posts 41 photos | Hi David

Thank you for the reply. I am going to do them as your first suggestion.

soon find out just going to start now.

How are you enjoying the snow up here.

Bob |

| David Clark 1 | 02/01/2010 10:48:02 |

3357 forum posts 112 photos 10 articles | Hi There

Very little snow.

Bit of ice left but nice blue skies.

Bit too far north for much snow.

regards David |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in