Oscillating Engine Simulator

| James Stanley | 20/03/2023 14:15:03 |

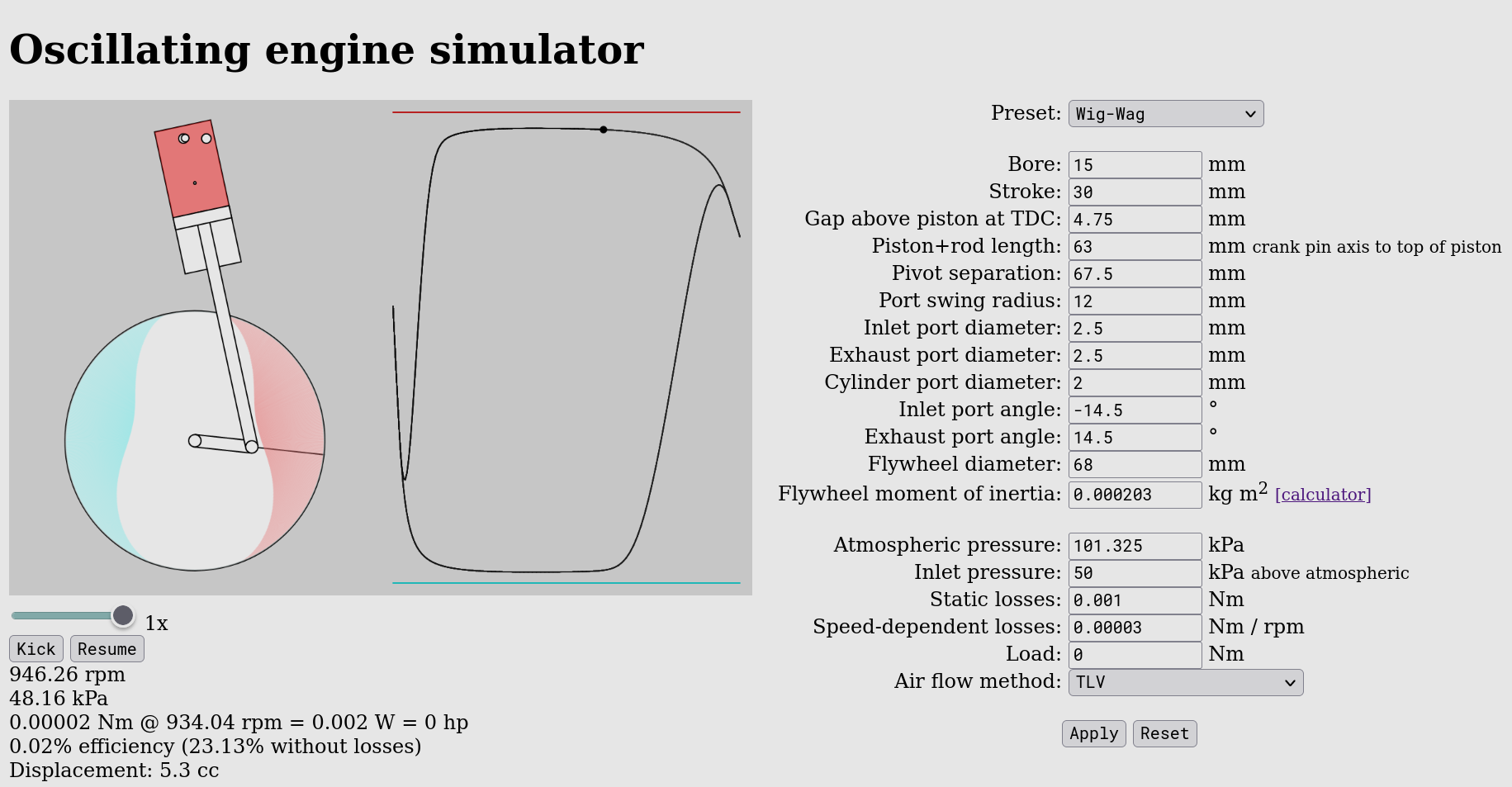

| 7 forum posts | (My apologies if this is not the correct section of the forum, I couldn't work out a better fit). I've been working on a simulator for oscillating engines that I would like to share in case anyone is interested, you can use it online: https://incoherency.co.uk/oscillating-engine/ The colour in the cylinder is an indication of the pressure (red is high, blue is low). The colours shown on the flywheel indicate the port timing (red means inlet port open, blue means exhaust port open, the thickness tells you how wide it is open). The plot on the right-hand side is a pressure-volume diagram, with the blue and red horizontal lines representing atmospheric pressure and inlet pressure respectively. I think it should mostly be physically accurate, the main weaknesses are: 1. it assumes the supply pressure in the inlet does not momentarily drop when the port is open, even if you make the hole really large. 2. I don't have a decent model for the inherent friction losses in an engine, so you might find that the simulated engine ticks over substantially faster or slower than a real one with the same parameters - in this case please let me know and I'd be keen to integrate your data into the loss model! If you want to know more or need help using it just ask. I also have written a blog post that goes into more technical details: https://incoherency.co.uk/blog/stories/oscillating-engine-simulator.html Edited By James Stanley on 20/03/2023 14:16:37 Edited By James Stanley on 20/03/2023 14:16:51 |

| Martin Johnson 1 | 20/03/2023 14:59:58 |

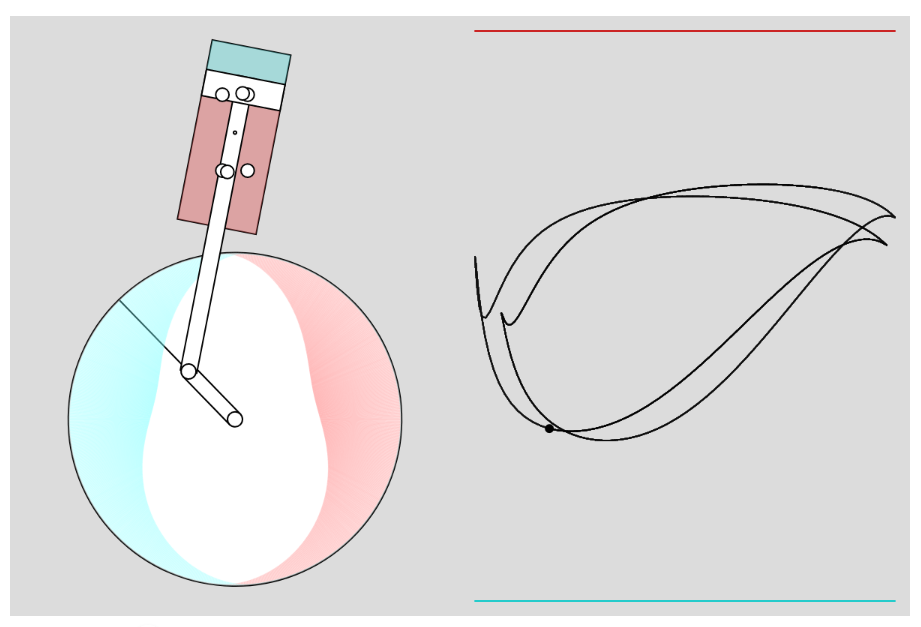

| 320 forum posts 1 photos | Interesting addition - Dockstader treatment for oscillators! Well done. I am intrigued by the compression loop and even more intrigued by the expansion loop. So what is going on there? I suspect managing those loops could be key to getting good running. Martin |

| Bazyle | 20/03/2023 15:39:19 |

6956 forum posts 229 photos | Fantastic. Can we persuade you to do one for a compound steam engine?

|

| SillyOldDuffer | 20/03/2023 15:50:49 |

| 10668 forum posts 2415 photos | I'm impressed too: not just the simulator but James' other activities. More fascinating reading when I should be working. Anyone who introduces himself with 'The writing is bad and the stories are not very interesting' is my kind of guy! More please! Dave

|

| duncan webster | 20/03/2023 16:12:30 |

| 5307 forum posts 83 photos | Excellent, keep up the good work. Of course you now need to confirm results by experiment. Not stupendously difficult, pressure sensor on cylinder, slotted wheel on crankshaft and a data logger. |

| James Stanley | 20/03/2023 21:15:07 |

| 7 forum posts | Thanks for the kind words! And Bazyle I don't think very many people make their own CPU any more, but if you are interested there is a great page at **LINK**listing some of them. > I am intrigued by the compression loop and even more intrigued by the expansion loop. So what is going on there? If you assume that the inlet and exhaust ports are symmetrical, then it is always the case that either the port timings overlap each other, or there is a range of positions, crossing top dead centre and bottom dead centre, where neither port is open. This means there is no way to avoid at least a little bit of unwanted compression and expansion, without letting both ports open simultaneously. I don't have a good intuition for whether you would be able to solve this by making the port locations or sizes asymmetrical - my guess is no, but it might be interesting to fiddle with. I don't think this unwanted compression/expansion actually costs any *efficiency*, because the work extracted in one cycle of the engine is given by the volume enclosed by the pressure-volume diagram. The pressure spikes enclose no volume, so they waste no energy (i.e., the energy you spent compressing the air on the approach to top dead centre is given back when the air expands after you pass top dead centre). It does however slow down the engine: compare rolling a ball up and down a frictionless hill to rolling it along a flat plane. The ball loses kinetic energy going up the hill and regains it coming down the hill, but it still takes longer to travel any given distance because the average speed is lower. > Can we persuade you to do one for a compound steam engine? Quite possibly! There are 2 different directions I want to take this. One is to make it simulate more than just simple single-cylinder single-acting oscillating engines. It would be relatively straightforward to split out the part that computes port overlap areas, and turn it into a pluggable "valve operation" module, where you can select what type of valving the engine has. Making multiple-expansion engines should be relatively easy as well - you'd probably model it as a fixed-volume vessel connecting the exhaust port of one cylinder to the inlet port of the next, and all the air flow calculations remain pretty straightforward. Double-acting cylinders would be similarly straightforward. Probably the most annoying parts of supporting different types of engine would be making the visualisation and the user interface handle all the different possibilities. The other direction I want to take it is to have it take some constraints and goals, and then it would automatically fiddle with the engine parameters to try to optimise the engine. For example, with displacement below 5cc, with 20 psi air supply, find the most efficient engine that can supply at least 1 Watt, below 1500 rpm. > Not stupendously difficult, pressure sensor on cylinder, slotted wheel on crankshaft and a data logger. Yes, I think this would be very interesting to do. Sadly I'm much less competent as a machinist than as a programmer, so my engine build is progressing much more slowly than my simulator did. But I definitely want to try to plot a pressure-volume diagram from a real engine. I suspect the limiting factor will be finding an inexpensive high-frequency pressure sensor. |

| Hollowpoint | 22/03/2023 08:33:22 |

| 550 forum posts 77 photos | This will be useful to me. I have a steam engine with several parts missing, including the piston and cylinder. I can use this to work out how to make the best replacements. 🙂👍 |

| James Stanley | 22/03/2023 18:15:37 |

| 7 forum posts | I'd be really interested to hear how that turns out. I'm not sure how applicable the results will be if your engine is not an oscillator however. |

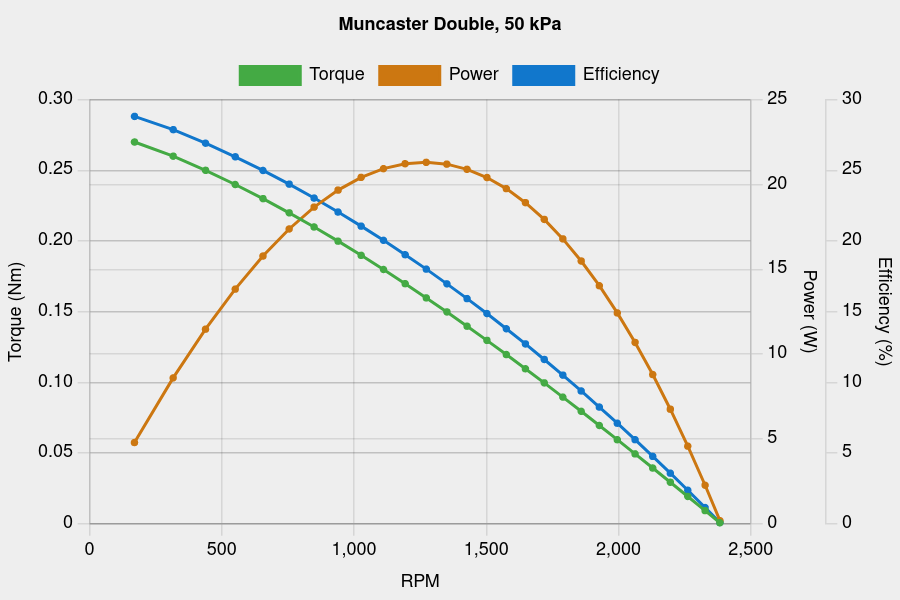

| James Stanley | 27/03/2023 10:12:46 |

| 7 forum posts | The latest version now:

|

| Martin Johnson 1 | 27/03/2023 12:55:22 |

| 320 forum posts 1 photos | Thanks for the clarification James. There is certainly more to these simple little engines than meets the eye. Martin |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in