Material for traction engine gears

| Andy Stopford | 13/09/2022 20:15:26 |

| 241 forum posts 35 photos | I'm building the 1" Minnie and am going to make the gears myself. The book suggests buying steel gears, but I was wondering whether cast iron would be easier on my Cheapo Chinese gear cutter set. I haven't tried them yet, but I've heard they tend to wear quite quickly (the cutters that is). I don't want to use brass (or plastic!) on appearance grounds. Has anyone any thoughts on this? |

| Andrew Johnston | 13/09/2022 20:41:22 |

7061 forum posts 719 photos | On my engines the crankshaft gears are steel, EN8: The 2nd shaft gears, final drive pinions, and final drive gears are cast iron: The bevel gears in the differentials are also cast iron: Cast iron would be prototypical. I am building relatively large engines where tooth loads on the crankshaft gears tend to need medium carbon steels, but I suspect cast iron was used in full size. I have used cheap gear cutters for experiments, but I'd be wary about using them for real gears. The ones I have never seemed to run true. I doubt that cutting a small number of gears, steel or cast iron, will blunt them. Andrew |

| JasonB | 13/09/2022 20:51:17 |

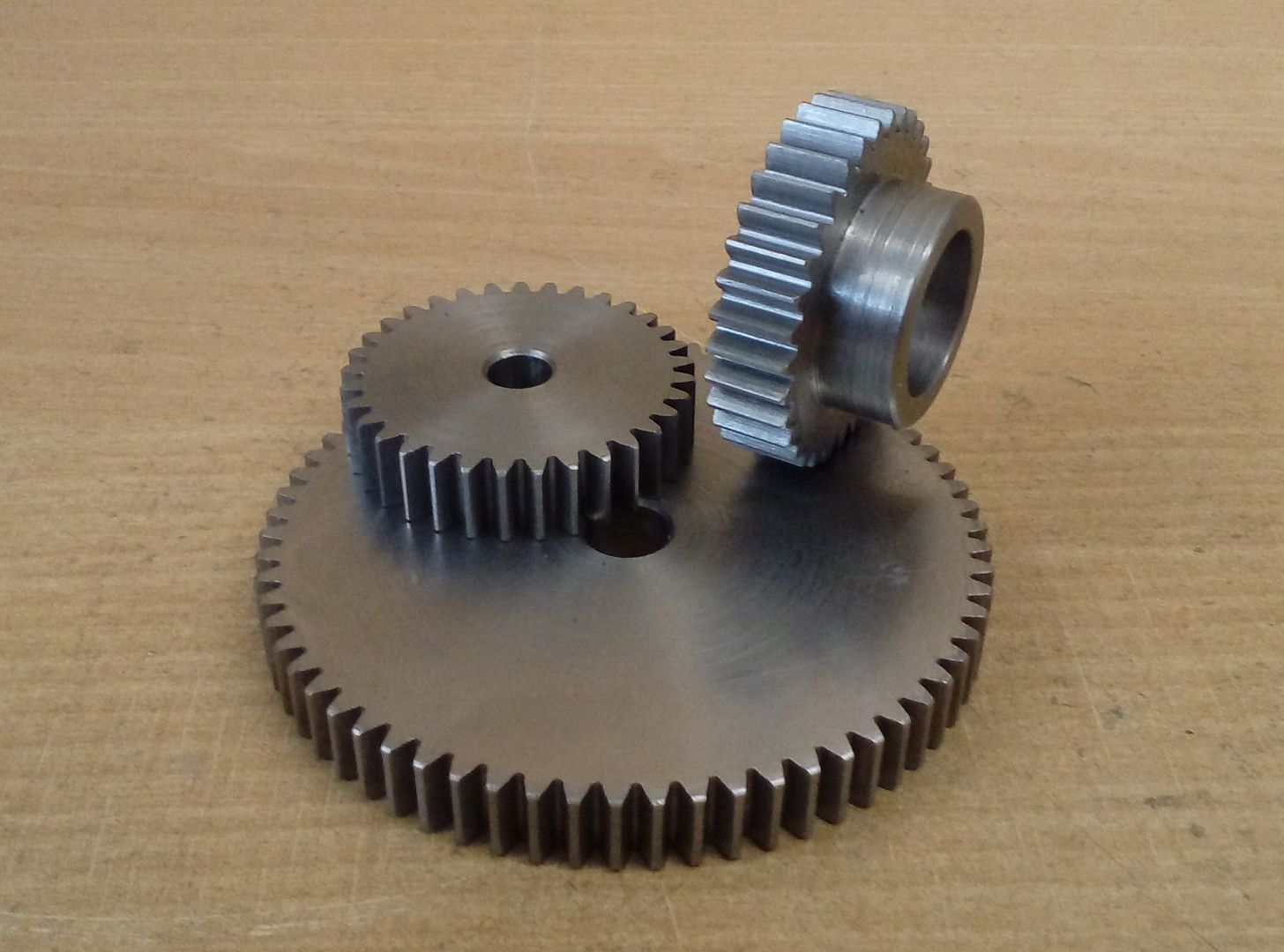

25215 forum posts 3105 photos 1 articles | I bought some very cheap chinese ones and would say they wore quicker than the reasonably priced ones from China via RDG. Still got a few gears out of them and at a few quid each could be considered disposable. You would probably still want to do the crankshaft gears in steel so the cluster can be soldered together but CI will be OK for the larger ones. My Fowler has a mix of steel on teh smaller ones and the final drive is a casting. Superba that I have castings for has mostly iron gears. These were cut from steel with the very cheap cutters

|

| Andy Stopford | 13/09/2022 21:22:17 |

| 241 forum posts 35 photos | Thanks chaps, steel for the crankshaft gears and CI for the others sounds like a plan. The ones Jason shows look like a pretty decent result from the cheap cutters - I'll watch out for them not running true |

| bernard towers | 14/09/2022 23:06:43 |

| 1221 forum posts 161 photos | What's the matter with silver soldering cast iron? |

| JasonB | 15/09/2022 06:56:16 |

25215 forum posts 3105 photos 1 articles | Some people find it more difficult though I have done it myself and with the small bores involved on the Minnie removing the carbon after you have driven it to the surface by heating could be a bit fiddly.

As Andrew said tooth loads on the crankshaft gears will be higher too though not many tend to try and get a Minnie to pull them along |

| SillyOldDuffer | 15/09/2022 11:57:38 |

| 10668 forum posts 2415 photos | Posted by bernard towers on 14/09/2022 23:06:43:

What's the matter with silver soldering cast iron? Carbon (as Graphite). Cast Iron isn't a single alloy, it's a family. Some of them contain much more free Carbon than others, and Silver Solder can't bond to Carbon. So you get chaps who find cast-iron is easy to silver-solder and chaps who find it very difficult: they're both right - it depends on the type of cast-iron they are working with. I noted Jason's comment with interest: 'removing the carbon after you have driven it to the surface by heating could be a bit fiddly'. Exposing more Iron by heat with an oxidizing flame sounds a good idea because flux has no effect on Carbon. Strong heat needed I think: though Iron acts as a catalyst and drops the ignition temperature of Graphite from over 740°C, the flame still needs to heat the surface to over 600°C. Dave |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in