Newcomen Atmospheric Engine

| Michael Moore | 11/09/2022 11:56:50 |

36 forum posts | Hi Just wondering about the process for the cool water injection into the cylinder to create the vacuum. Do we know how was this was done on an early 18th-century Newcomen engine, and how it's done on models of today.

I thought perhaps with gravity by housing water higher than cylinder, but I'm not sure if this would work as I'm an absolute beginner to models, engineering, physics, etc.

Ta,

|

| Michael Gilligan | 11/09/2022 14:07:45 |

23121 forum posts 1360 photos | This shows a simple header tank, Michael : **LINK** https://www.nms.ac.uk/explore-our-collections/stories/science-and-technology/newcomen-engine/ Sorry, I have no experience of scaled-down model versions. MichaelG. |

| Dave Wootton | 11/09/2022 14:38:23 |

| 505 forum posts 99 photos | There's a full size replica at the Black Country Living Museum in Dudley, fascinating to watch in steam and it is run when the museum is open. The staff are very friendly and knowledgeable. If you can't get there there will be info on their website. There used to be a Science museum book called James Watt and the separate condenser that had a lot on these early engines. Also David Hulse's website has details of his wonderful models of early engines, can lose yourself there for a while! Fantastic place worth a visit if you can. Edited By Dave Wootton on 11/09/2022 14:38:56 Edited By Dave Wootton on 11/09/2022 14:43:21 |

| SillyOldDuffer | 11/09/2022 15:13:38 |

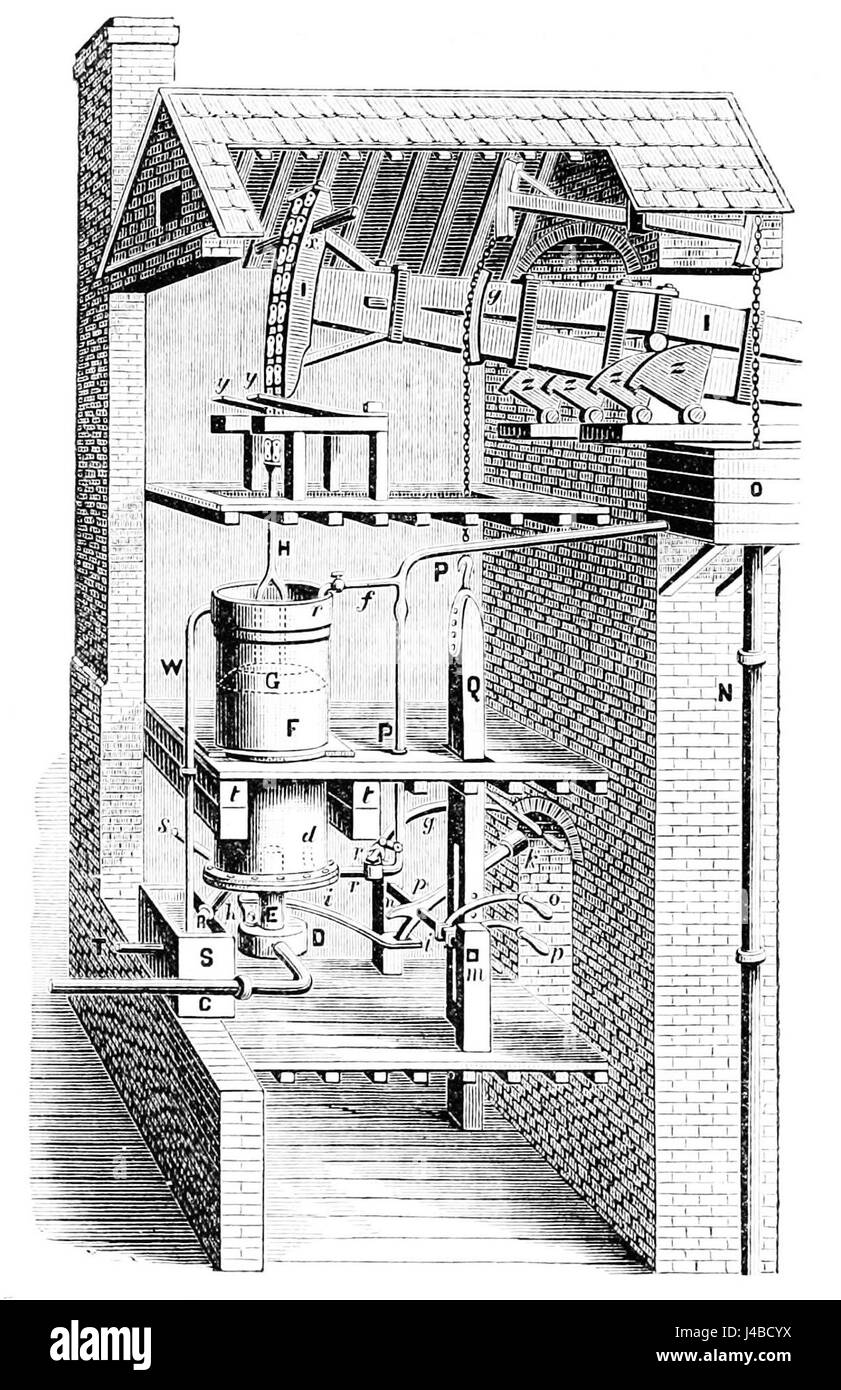

| 10668 forum posts 2415 photos | Depends I think on the date of the engine. This picture is of a Smeaton improved engine, he eventually tripled the efficiency of Newcomen's original by optimising the relationship between piston diameter and length of stroke, the number of strokes per minute, and the size of the boiler.

In this example the boiler isn't immediately below the cylinder, which I think means Smeaton was able to do better than the original pot boiler. However, the engine:

Modelling these engines is said to be difficult because they're intrinsically very inefficient plus their physics don't scale down well. The very best a vacuum can achieve is only 14psi which can't put much force onto a model sized piston driving quite a lot of mechanism. And on practice the vacuum will be much less than 14psi because the surface area of the small cylinder and piston is large compared with their volume. Thus heat is lost rapidly even before any cold water is sprayed in, and there may not be enough vacuum at the right time to rock the beam. Bigger is definitely better when it comes to atmospheric engines. Dave |

| Howard Lewis | 11/09/2022 15:46:06 |

| 7227 forum posts 21 photos | You can see how James Watt improved efficiency by moving the condensation process out of the cylinder to reduce heat loss within the cylinder. With such a small pressure difference the piston and cylinder need to be large to produce enough power merely to overcome friction and accomodate the heat lost to the incoming steam caused by the in cylinder condensing. Friction will be proportional to the cylinder diameter (Circumference ) while area (Force available ) will increase as the square; so bigger is better. Howard |

| Michael Moore | 11/09/2022 17:39:30 |

36 forum posts | Thanks all. I'll attempt to process these posts and links tonight. Everything has to be read and watched scores of times before it sinks in with me. Ta. |

| Andy Carlson | 11/09/2022 22:12:08 |

| 440 forum posts 132 photos | Coincidentally I was looking at the example in Dartmouth a few days ago. IIRC Watt is supposed to have been working with a 'model' of a Newcomen engine when he made his improvements... which begs the question... how big was the model? |

| John Olsen | 11/09/2022 23:02:21 |

| 1294 forum posts 108 photos 1 articles | There is a working replica of a Newcomen engine in Whangaparaoa near Auckland NZ. It was built by the Auckland Steam Engine Society. When I say replica, there are no scale working drawings of any of the original engines, or any original engines to take drawings from, so the most we can say is that it is like the originals and works on the same principle. It stands about twenty feet high and the pumped water is used to turn a small waterwheel, maybe 6 feet or so in diameter. There was a kitset for a model one being sold a few years back, one of the local guys here in NZ bought one and it did work to at least some degree, with some difficulty at times. It was maybe 18 inches or so tall. John |

| Michael Gilligan | 11/09/2022 23:19:23 |

23121 forum posts 1360 photos | Thanks for the reference, John There is an interesting paper about that one : **LINK** https://www.tandfonline.com/doi/full/10.1080/17581206.2018.1463720?scroll=top&needAccess=true Fortunately for me … I have ‘Institutional Access’ Unfortunately for everyone else … I am not permitted to share the download Sorry MichaelG. . One short but important quote is permissible under ‘Fair Use’ This project has proven that small Newcomen engines can be made to work successfully and suggest that more ongoing research into the design of the valve gear of the early engines is required in the future. . keywords New Zealand built, 21st century, working (operating), Newcomen engine DOI 10.1080/17581206.2018.1463720 INT. J. FOR THE HISTORY OF ENG. & TECH., Vol. 88 No. 1, 2018, 135–163 Edited By Michael Gilligan on 11/09/2022 23:25:28 |

| Michael Gilligan | 12/09/2022 00:04:02 |

23121 forum posts 1360 photos | Both versions of this rather splendid image are freely downloadable, at quite a respectable resolution: https://collection.sciencemuseumgroup.org.uk/objects/co50905/print-of-henry-beightons-engraving-of-a-newcomen-engine-print MichaelG. Edited By Michael Gilligan on 12/09/2022 00:09:52 |

| John Olsen | 12/09/2022 06:25:15 |

| 1294 forum posts 108 photos 1 articles | Hi Again, I've created an album with some of my pictures of the construction of the Auckland Newcomen Engine. Hopefully this link will get you to the album, rather than overloading this thread with links to all the individual pictures. Auckland Newcomen engine album As you will see if you look at the picture of the top of the beam I was involved in the project sufficiently to get my name carved into the beam. In particular I remember cleaning a lot of those bricks. I think that might be me at the top of the engine when the half barrel was being hoisted in place. I've included one shot which shows part of a model Newcomen engine, not the best shot since it was really of the people, but it will give some idea of what the model is like. The flywheel belongs to another engine behind it. regards John |

| John Olsen | 12/09/2022 06:33:12 |

| 1294 forum posts 108 photos 1 articles | Getting back to the original question, I think that half barrel being hosted up in one of the pictures contains the water that is used for the condensation. It sits on top of the frame, although on an original engine it would probably have been somewhere in the engine house. It doesn't need a lot of head, since the pressure in the cylinder is never high. If anyone wants to use any of the images, I have no objection to any non commercial use like club newsletters or personal study. John |

| Michael Gilligan | 12/09/2022 07:05:06 |

23121 forum posts 1360 photos | Posted by John Olsen on 12/09/2022 06:25:15:

Hi Again, I've created an album with some of my pictures of the construction of the Auckland Newcomen Engine. Hopefully this link will get you to the album […] . Many thanks for sharing the pictures, John … and yes, the link works fine. MichaelG. . P.S. __ although Newcomen’s engine is hopelessly inefficient in technical terms, I have always considered it one of the finest examples of ‘Man the Tool-Maker’ … Edited By Michael Gilligan on 12/09/2022 07:24:06 |

| John Haine | 12/09/2022 07:46:15 |

| 5563 forum posts 322 photos | Our school history teacher told us a tale of a lad at a mine employed to turn the water and steam on and off. Being perennially sleepy he rigged up an arrangement of levers and string to do it automatically. Foreman found him asleep on the job and he was promptly sacked. |

| Michael Gilligan | 12/09/2022 08:08:06 |

23121 forum posts 1360 photos | Posted by John Haine on 12/09/2022 07:46:15:

… Foreman found him asleep on the job and he was promptly sacked. . Thus demonstrating the Peter Principle ? MichaelG. . P.S. __ the character at (c) in the engraving that I linked appears to be dozing peacefully Edited By Michael Gilligan on 12/09/2022 08:10:10 |

| SillyOldDuffer | 12/09/2022 10:44:00 |

| 10668 forum posts 2415 photos | Posted by John Haine on 12/09/2022 07:46:15:

Our school history teacher told us a tale of a lad at a mine employed to turn the water and steam on and off. Being perennially sleepy he rigged up an arrangement of levers and string to do it automatically. Foreman found him asleep on the job and he was promptly sacked. The boy Potter may be a myth, like Newton understanding gravity after being hit on the head by an apple and Watt being inspired to invent the steam engine by his mum's kettle lid lifting when it boiled. It's possible the "boy" in question is a misunderstanding. Another explanation is that early automatic atmospheric engines featured a Buoy Valve, which someone assumed meant a child was involved. Buoy valves aren't unlikely in pumping engines - Cornish Engines all had Cataract valves. (In British English buoy is pronounced boy, rather than Boo-ee in English as she is spoke in the USA! ) It's true the valves on Newcomen's first engines were operated manually and so it's possible the job was done by a real boy with strong practical skills and engineering insight. But if I'd built an expensive state of the art pumping engine to keep a costly coal mine dry enough to work in, I'm not sure I'd trust an unsupervised boy to drive it! More likely various clever experienced men tried a number of different methods, and settled on what seemed the best. At that point the small-c conservatives who infest British engineering seem to have taken over: a century later the beam and valve-gear on Watt's early engines is very Newcomen. We will never know whether or not the boy really existed unless something turns up in a musty archive. Dave |

| John Olsen | 12/09/2022 11:22:06 |

| 1294 forum posts 108 photos 1 articles | I suspect that the boy was a myth. With the Auckland engine the valves are worked manually until things are going well, then they work themselves. That sort of operation was actually still used on American walking beam steamers until the last years of their use, into the last century. The Cruquius engine in the Netherlands has something similar. John |

| michael potts | 12/09/2022 12:09:10 |

| 50 forum posts 2 photos | You need to get hold of a copy of 'The Steam Engine of Thomas Newcomen', by Rolt and Allen. Get the Landmark edition of 1997 if possible, it has a better bibliography. This book does mention a wide range of information about this engine. Gravity was used to give a pressure to the injection water. It was simple and effective. When John Smeaton started to look at the design of the engine around 1770, he said that the injection water system should be as high as possible in the engine house. He also specified that the injection water nozzle should be square. This broke the jet up to provide a better spray. To see how this works, look at the internet site ' physicsgirl smoke rings ', and see the effect of blowing a square smoke ring. Water, being denser than air would be slightly different, it would tend to fly outwards. Getting water up into the injection tank was an interesting problem. The Thomas Barney 1719 engraving of the Dudley Castle engine shows a small pump connected to the beam by a heavy connecting rod to pressurise the water sufficiently for it to rise to a level where it could flow into the injection cistern. The jack head pump came a little later ; it was connected on the main pump end of the beam by a light chain. As the main pump was lifted, the jack head piston was also lifted, forcing water up a pipe to the cistern. The John Smeaton engine drawing shows a more complicated arrangement using an auxiliary beam to operate a lift pump by a chain connection. Model Newcomen engines have different problems, you would probably need a small motor driven pump to supply injection water at three or four psig. The main pump on such an engine works best using a jack head pump with an adjustable valve to control the flow of water from the pump. A friend of mine had a model engine, built by a toolmaker from his scrap box. I first saw it about 1998 or 99 at a Heritage weekend at Elsecar. I walked into a room with this model working away in a corner, started talking to the operator, and over twenty years later we are still talking. His engine was driven by steam from a pressure cooker, ran very effectively, and provided information about these engines that can be found nowhere else. This engine has now worn out, he has another that he built based on the Dartmouth engine. The single lever valve gear has caused problems, so is probably unsuitable for a model. He thinks that model Newcomen engines can work very well, but do need care, starting with the fit of the piston in the cylinder. The model Newcomen engine that James Watt worked on still exists. It is in the Hunter Museum in Glasgow, an example of a clock maker's or instrument maker's skill. There is a similar model in Kings college at the University of London. Jim Andrews wrote a paper about the differences between the Newcomen and Watt engines, and gave talks about it. The paper does not appear to have been published. Over the last three hundred years a huge amount has been written about the Newcomen engine. The Newcomen Society has published nearly ninety papers about it. Over thirty years ago I began to read about it, and when I was deemed too expensive to employ in 1992, I began work on a patented version dating from 1790, the Heslop engine. Twenty years later I had just about worked out who did what and when and read a paper to the Midlands branch of the Newcomen Society when a row broke out about the site of the 1712 Newcomen engine. So, along with some other people I started to look at the evidence. I did come to a conclusion about it that fitted with some of the contemporary writings ( Well, about thirty years after. ) I have continued to collect information about this engine and others. We still have large gaps in our knowledge and understanding of these machines. People talk about the lack of efficiency of these machines, but at the time there was nothing else that could get water out of mines, apart from water wheels and windmills. The problems that they had are still with us in renewable generation of power. I think that is all for now. The history of this engine sprawls everywhere, and fresh items keep coming to light. In 2020 I found nine separate items from auction sales to paintings, drawings and one article about a well known engine that I did not know existed. Two items allowed me to estimate the size of engines that we know existed, but knew nothing about. If you think that we do not know a lot about English engines, then the Scottish engines hardly exist at all, and European engines are very difficult to find anything about apart from the fact that they existed in some cases. If anyone has any further questions I would be happy to discuss them. Regards. Mike Potts. |

| michael potts | 12/09/2022 12:23:08 |

| 50 forum posts 2 photos | The valve gear ? My colleague thinks that Thomas Newcomen ever rented a commercial engine with hand operated valves ; the dangers of a disaster were simply too high. We know the Dudley Castle engine had automatic valve gear, because when it was started up for the first tie, ' It made several strokes very quick '. This could not have happened with manual gear. The story about the boy running the first prototype engine in Cornwall about 1703 could well be true. No one else had the opportunity to actually see what was happening. It is noticeable that the steam valve operation is simple, but the injection water valve operation is much more complicated,using the ' Potter cord '. . Sorry for these omissions. Regards. Mike Potts.

|

| Michael Moore | 12/09/2022 13:07:14 |

36 forum posts | Thanks to all for the posts, picture albums, and links, they're helping me get a better understanding. I do plan to visit the Newcomen engine in the Black Country at some point as I'm fairly close in North Brum.

I've found what looks to be an interesting video lecture (youtube) by Mike Potts on the history of the Newcomen engine. I fell asleep watching it last night, but I plan on finishing tonight. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in