crankcase construction

| Perko7 | 25/04/2021 13:24:28 |

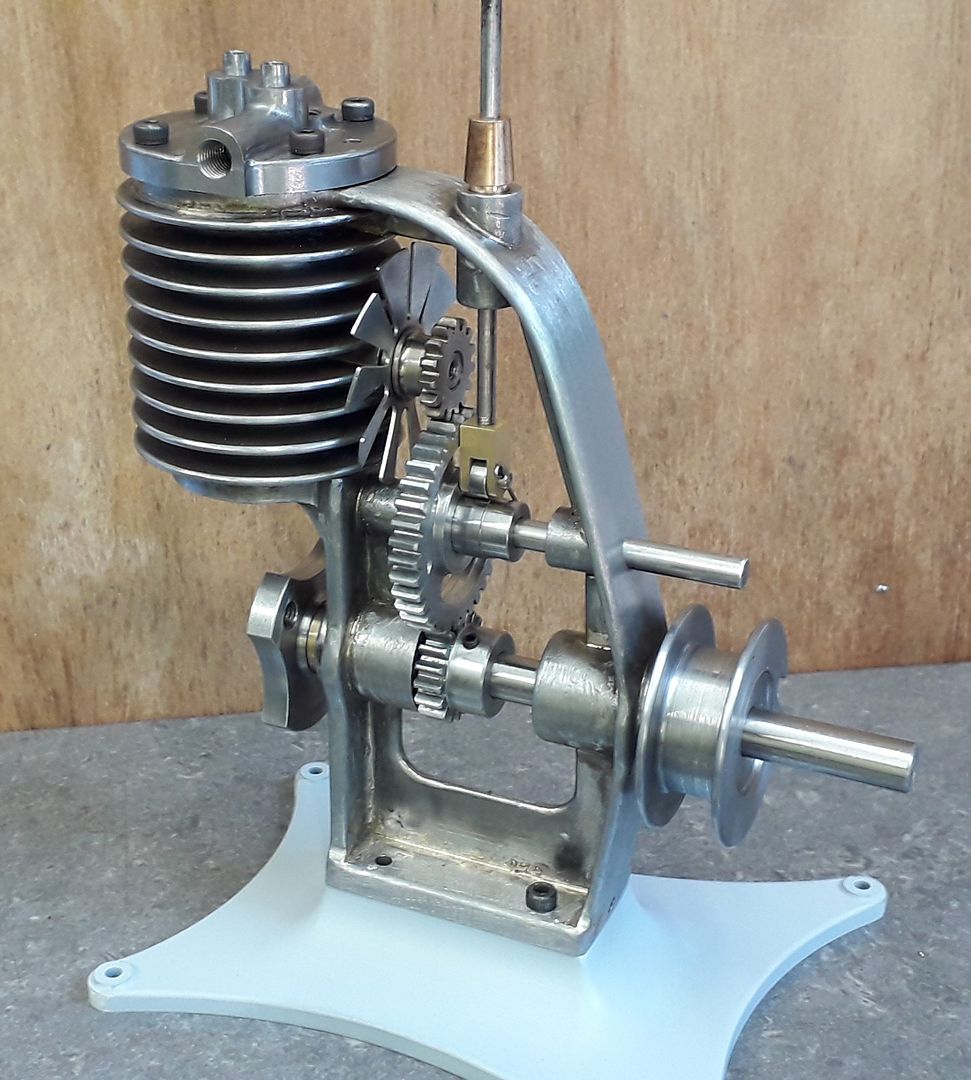

| 452 forum posts 35 photos | I'm told there's no such thing as a stupid question, so here goes..... Has anyone on this forum ever tried making an i/c engine crankcase using pieces of steel sheet and tube of suitable thickness welded or silver-soldered together? I'm thinking of a water-cooled 2-cylinder ohv about the size of an ETW Wallaby or similar. Reason I ask is I have an idea for an engine i'd like to make but there are no castings available for it and it's a bit too complex to machine from solid. I've seen plenty of descriptions of guys fabricating steam engine cylinders and valve chests silver-soldered together and can't see any reason why the same approach would not work for an i/c engine. Prepared to have my naive musings shot to pieces but be gentle |

| JasonB | 25/04/2021 15:53:29 |

25215 forum posts 3105 photos 1 articles | If the weight won't be an issue then no reason not to. I've certainly done a few open crank engines that used a combination of welding and silver soldering to form the cases. Also done cylinders for IC engines by the same method. I find it is best to rough machine the parts leaving 1mm or so on any critical areas in case things distort or move during fabrication. Then treat the structure much like a casting doing the final machining when it is all together.

Edited By JasonB on 25/04/2021 16:04:54 |

| Tim Stevens | 25/04/2021 16:46:34 |

1779 forum posts 1 photos | There is one factor in your question which is particularly important - the difference in the pressure generated by direct combustion, and by the expansion of steam. Direct = much fiercer bangs. As long as there are direct (straight) lines of strong material (usually steel) holding the the cylinder head and the main bearings in a firm permanent relationship, you are on the way to success. Cheers, Tim |

| Howard Lewis | 26/04/2021 01:14:41 |

| 7227 forum posts 21 photos | Why not? The original HST was powered by Paxman Ventura engines where the crankcase was fabricated. You could always through bolt, so that the cylinder head studs fit into the crankcase, relieving the cylinder liner of any of the forces liable to distort it., and improving sealing at both ends. Howard Edited By Howard Lewis on 26/04/2021 01:15:16 |

| Jon Lawes | 26/04/2021 06:15:16 |

1078 forum posts | I attended a lecture at Bristol University by one of the lead designers from TVR. He was talking about the TVR Speed 12, and mentioned that the original homologation rules called for a very low number of cars needing to be produced, so they just fabricated the blocks from welded plate. Then the homologation rules were finalised for the class they were racing in and the numbers were much higher, so rather than redo the design they just built these engines on a production line, out of welded plate... For those interested, Some other interesting gems came out of that lecture, such as the Speed 12 radiator being part of the space frame (so you basically had to repair it or unweld it...), that they tried running the exhausts down the prop tunnel but realised the diff cooler was going to need to be bigger than the radiator... it was originally going to be a Speed 10 but at the time only Dodge made a 10 cylinder engine and as rivals they were told to poke off when they asked to use their ignition system so TVR made it a 12 cylinder engine instead... |

| Roger B | 27/04/2021 10:55:38 |

244 forum posts 105 photos | Roy Amsbury built a 120cc V8 with a silver soldered brass crankcase. This was featured in ME starting 3rd May 1991. |

| Perko7 | 28/04/2021 12:18:29 |

| 452 forum posts 35 photos | Thanks all for those responses, the verdict seems to be that it is quite likely to achieve a successful outcome provided I treat the assembly as if it were a casting and incorporate some extra meat where needed to allow for fixings and for machining to final dimensions. Now to draw it up and see how I can fit it together with suitable locating tabs to maintain alignment while welding. Should be fun....... |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in