James Coombes

| Steve Withnell | 24/04/2021 12:15:08 |

858 forum posts 215 photos | After too many years languishing under the bench, I finally pulled out my James Coombes build. I was pleased to find I'd made much more progress than I remembered, but I hadn't stuck to plan! I'd never liked the table columns, it didn't seem right to transition the round columns to a square platform. Just me being a bit OCD, so I turned them from square bar, so I could create a square plinth top and bottom. I'm pleased with how they look, but it has created a fitting problem - the valve gear bearing blocks screw directly on to the threaded posts that secure the columns. Any misalignment in the thread axis is corrected by rotating the column.

Steve |

| JasonB | 24/04/2021 13:13:35 |

25215 forum posts 3105 photos 1 articles | If you know the pitch of the thread then leave the posts long and screw them into position, work out how much more they need to rotate to line up and then divide the pitch by that amount / 360 and machine that amount off the bottom of the post. Alternative is to turn off teh square capital and base and make them as separate pieces Edited By JasonB on 24/04/2021 13:14:31 |

| Jim Nic | 24/04/2021 16:53:26 |

406 forum posts 235 photos | +1 for turning off the square capital and using separate pieces which are free to turn on the longer threaded portion of the column. That is what I did on my first table engine, not a James Coombes but a Stew Hart. I actually drilled and tapped the columns to take studs to save making all new columns. Jim |

| Wayne Jepson | 02/12/2022 05:06:52 |

| 4 forum posts 3 photos | Did you make the con rods yet? I read all your original”with chips” posts and find them very useful. Just starting a James Coombes build myself. Thanks |

| JasonB | 02/12/2022 07:43:23 |

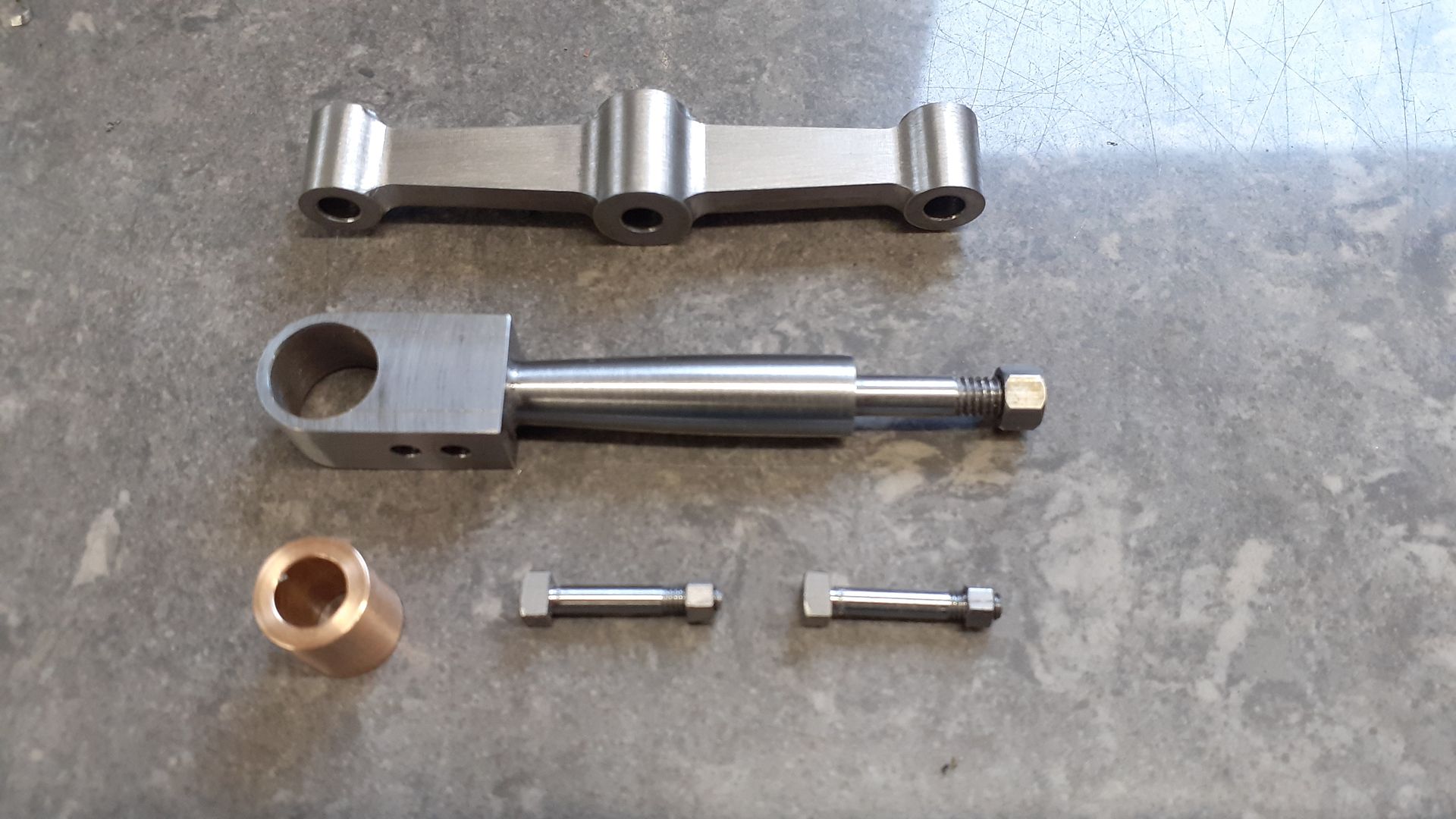

25215 forum posts 3105 photos 1 articles | Coming back to the original question, if you have not got over it by now than moving the supports to another position is also an option and one that I have gone for on my much modified JC.

I'll be doing my conrods in the next week or two if you have any questions Wayne, the short one and the yoke were completed last weekend I'm not soldering as per the Stuart design but bolting together.

|

| Wayne Jepson | 03/12/2022 16:58:54 |

| 4 forum posts 3 photos | Looks great thanks, please keep posting your progress because I’m going to closely follow your build while doing mine. I think your toke looks much better than the original design.

wayne |

| JasonB | 04/12/2022 07:27:38 |

25215 forum posts 3105 photos 1 articles | Wayne, I tend to do most of my posts about an engine once it is finished with just the odd progress shot during the build. But if it helps the photos are being added to this album and feel free to ask about anything. Although I have used my CNC for a few bits it could all be done with manual machines with a few slight alterations, from the look of your No9 you should have no trouble with a JC. Probably best to start your own build thread on here. PS the album will default to newest first so either change that or start at the end and look backwards so images are in order. Edited By JasonB on 04/12/2022 07:29:04 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in