Emco servo conversion - compact 5 cnc

| sam sokolik | 20/05/2020 17:10:07 |

| 126 forum posts | I finally got back to the Emco project after a few years. Squirrel! I had thrown it together trying out some pwm drives I had - which seem to work great. When I started pllaying with the spindle I started getting noise. (sporadic estop pulses). (mainly because in my excitement of the servos working well - I didn't pay much attention to grounds..) |

| sam sokolik | 21/05/2020 03:34:26 |

| 126 forum posts | addendum... There was a setting in the ini file that was capping the acceleration at 6in/sec^2.. No wonder why it looked so good. So - upping the acceleration to 50in/s^2 I get a peak following error of .0002" (10 encoder counts - which is exactly what I would expect) Now it feels as expected - accelerating to 150ipm is pretty instant. sam |

| Manofkent | 21/05/2020 07:26:57 |

| 145 forum posts 29 photos | Hi I presume you are using service motors fitted with encodes? What encoder interface have you used? John |

| sam sokolik | 21/05/2020 15:25:21 |

| 126 forum posts | Posted by John Hilton on 21/05/2020 07:26:57:

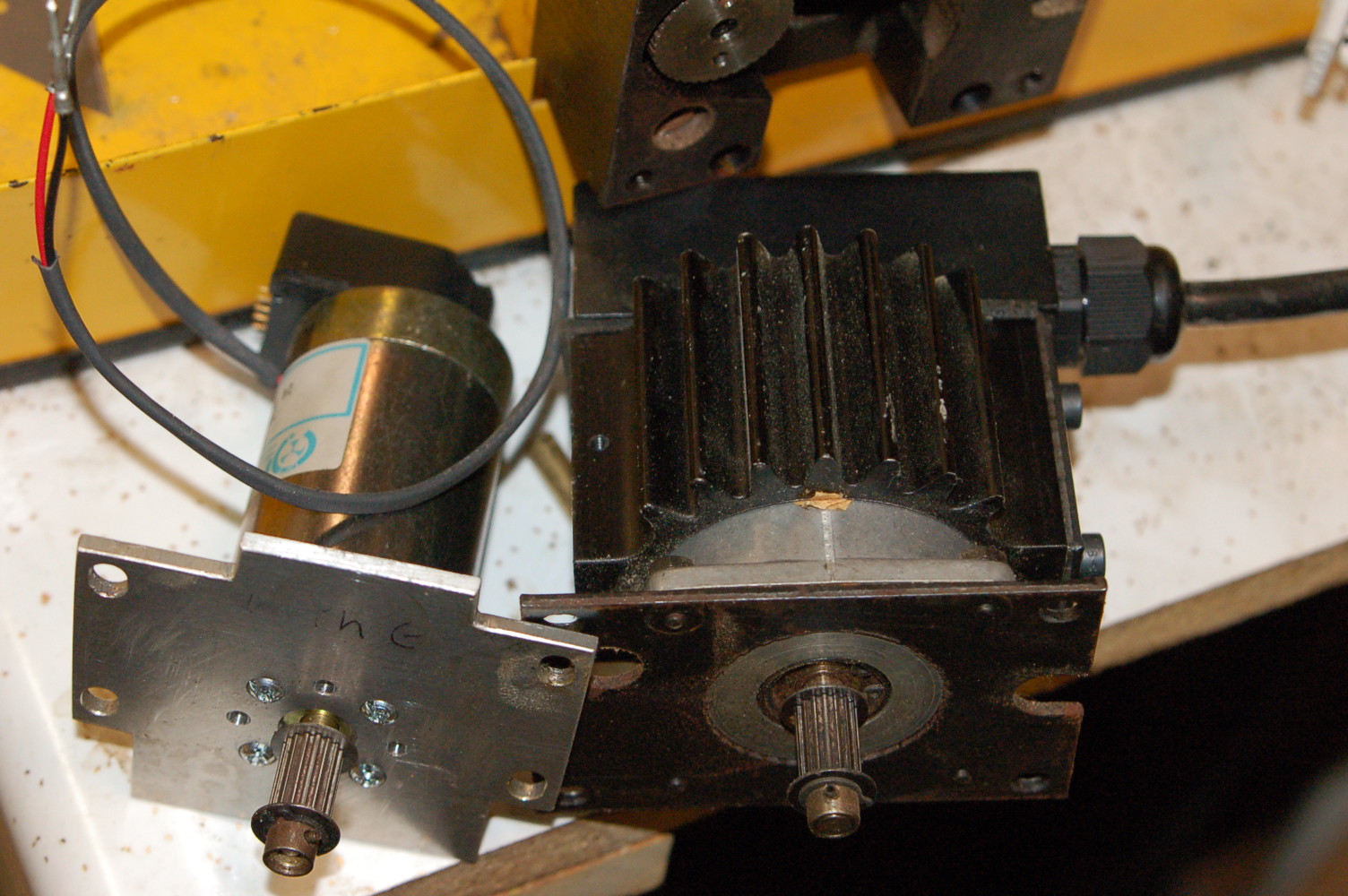

Hi I presume you are using service motors fitted with encodes? What encoder interface have you used? John Yes - some Pitmann servos that came with 500 line encoders. I am using Mesa interface hardware that does the high speed pwm and encoder counting. (5i25) which acts like 2 super high speed printer ports. (expandable - you can get daughter boards that do all kinds of cool stuff - analog servos, steppers and such) I am using it in kinda unconventional way (think cheap a$$) (mesa + cheap bob) |

| sam sokolik | 24/05/2020 14:16:40 |

| 126 forum posts | A bit of an update |

| sam sokolik | 01/06/2020 21:10:53 |

| 126 forum posts | some machining required...

|

| sam sokolik | 07/06/2020 21:49:07 |

| 126 forum posts | Getting there |

| sam sokolik | 13/07/2020 05:12:15 |

| 126 forum posts | |

| sam sokolik | 13/07/2020 05:15:32 |

| 126 forum posts |

|

| Former Member | 13/07/2020 08:11:56 |

[This posting has been removed] | |

| Dave Smith 14 | 13/07/2020 08:48:08 |

| 222 forum posts 48 photos | Great result, but please keep your fingers away from the moving parts even a small machine will take a finger off. |

| Joseph Noci 1 | 13/07/2020 14:54:33 |

| 1323 forum posts 1431 photos | Still nine fingers left then though...

Sam, what CAD/CAM software did you use to generate the cut file? Is the cut file G_Code? I wonder how practical some live tooling would be on a setup like that? A third axis in Z bolting in place of the tool post with an ER spindle - would make the bolt head a lot easier on the machine! Very nice setup - servos are certainly well tuned! Nice job! Joe |

| sam sokolik | 13/07/2020 15:05:55 |

| 126 forum posts | Posted by Dave Smith 14 on 13/07/2020 08:48:08:

Great result, but please keep your fingers away from the moving parts even a small machine will take a finger off. Agreed - I was unprepared for the first run of the program. |

| sam sokolik | 17/07/2020 04:20:54 |

| 126 forum posts | more close up action... |

| Joseph Noci 1 | 17/07/2020 08:10:38 |

| 1323 forum posts 1431 photos | Sam, what CAD/CAM software did you use to generate the cut file? Is the cut file G_Code? |

| sam sokolik | 17/07/2020 16:09:54 |

| 126 forum posts | That was all by hand gcode. The actual polygon turning is currently done by sending info to hal layer from gcode.. I hope to do a remap but I am not there yet. So something like (this is on the mill - polygon boring) (polygon radius) (enable polygon component) (disable polygon component) m65p0 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in