INT30 sensitive drilling attachment

| Mark Davison 1 | 31/10/2019 08:20:07 |

| 134 forum posts 38 photos | I've just bought a Harrison vertical mill with INT30 spindle (although not yet collected it). I bought this despite being reluctant to buy a mill without a quill, primarily as I don't have the height for a Bridgeport type machine. I want to be able to do some drilling on the machine and stumbled across this on **LINK**

I'm looking to make something like this but using a straight shank ER collect chuck inserted directly into an INT30 to MT3 adapter (such as the one below - 87mm long extension) that has had the morse taper bored out to a parallel 25mm hole. What are my chances of boring out this supposedly hardened INT30 adapter with carbide tooling and getting a satisfactory surface finish? Or should I sleeve after boring, say with brass, and then bore that?

|

| Emgee | 31/10/2019 08:54:12 |

| 2610 forum posts 312 photos | Hi Mark Good idea to save cranking the knee to drill but with a 1/2" drawbolt doesn't give much material for the operating shaft, could be in danger of the chuck part going AWOL. An alternative solution would be to motorise the knee with a stepper and simple controller. Emgee |

| IanT | 31/10/2019 09:48:17 |

| 2147 forum posts 222 photos | I have the same lack of 'quill drilling' problem on my horizontals Mark. The Victoria has a MT3 vertical head and my thinking is that I will drill (and lap) a hole in a MT3 blank arbor to take an ER16 collet chuck (with straight 12mm shank) and basically build a larger version of the ArcEuro Trade sensitive drilling adaptor. The down feed will probably be via a lever under the head though (not acting through the spindle) - so no problems with the drawbar. I'll mill a slot in the MT3 bit and place a drive pin in the ER16 shank. Might have to slim the back of the chuck head to take a smaller bearing - or come up with a revolving pressure plate behind it to bear down on. The ER16 collet will hold drills up to 10mm - larger than I actually need generally. You could do the same with the INT30/MT3 adaptor - and use the outside of this to hold the down-feed lever mech. Same general idea but an easier approach I think - blank arbors not being hardened and they cost a bit less if you screw it up (which of course I'm sure you won't ). Anyway - that's what it says under "Quills" on my TUIT list.... Regards, IanT |

| DC31k | 31/10/2019 16:42:49 |

| 1186 forum posts 11 photos | Have a look at how Schaublin do their sensitive drilling attachment for the 30 taper spindle on the 13 mill. It locates on the spindle nose itself, like a big facemill would. Much easier to make than something that locates in the taper. You need to think of how the drive will be transmitted while still allowing sliding movement. Generally done with a key and keyway. A dog point grub screw into the 3MT adaptor could be used, but requires tapping a hard part. An accurate keyway is equally difficult in a hardened ER straight shank chuck. Copying the Schaublin design would allow you to put keyway in unhardened spindle nose adapter and use angle grinder to form a not-very-precise-over-wide slot in ER chuck and then JB Weld in a key (using the adapter to keep it aligned while it sets). See bottom left of page 6 here: https://drive.google.com/file/d/0Bxr59DtuJda_amx1V1dvNE8xVXM/view?usp=sharing (Anglo-Swiss Tools, Schaublin 13, French catalogue) for nose dimensions. Top right of page 12 for attachment complete. I have a drawing for all the Schaublin parts so if you PM me with contact details, I can send to you. |

| old mart | 01/11/2019 19:47:13 |

| 4655 forum posts 304 photos | Just a thought, but these boring heads are screwed onto the arbor, and if you have a lathe, you would have more options to design the keyed sliding part, and also have a boring head at the same time.https://www.ebay.co.uk/itm/SOBA-50-mm-Boring-Head-Complete-with-Tools-INT-30-Shank-Metric-17113030-ISO30/372164615910?epid=3011275466&hash=item56a6bd5ee6:g:kRIAAOSwDFBaL9SP An er32 collet holder also has a thread which has potential. Edited By old mart on 01/11/2019 19:47:58 Edited By old mart on 01/11/2019 19:50:51 |

| Mark Davison 1 | 01/11/2019 20:35:05 |

| 134 forum posts 38 photos | Thanks for the suggestions. I was hoping to use at least some of the depth of the INT30 taper so as not to loose too much of the available height. Once I collect it next week I'll see how important that is. I have a lathe and a MT3 boring head so will need to buy an INT30 one anyway. |

| old mart | 01/11/2019 21:14:15 |

| 4655 forum posts 304 photos | Its a difficult project, what with the core diameter of the pull stud being only 9.85mm and some method to allow the chuck shaft to move axially and turn with the toolholder via a keyway or similar. The stroke will be severely limited, if the whole assembly is not fairly long. These sidelock spindles may have the answer to the finish of the bore and the screws could drive a slotted spindle. |

| DC31k | 02/11/2019 08:37:07 |

| 1186 forum posts 11 photos | Posted by Mark Davison 1 on 01/11/2019 20:35:05:

I was hoping to use at least some of the depth of the INT30 taper so as not to loose too much of the available height. Using a spindle nose cap, it can project upwards into the taper to give the height and length for support, but does not need to be machined to fit the taper. |

| DC31k | 02/11/2019 08:46:19 |

| 1186 forum posts 11 photos | Posted by old mart on 01/11/2019 21:14:15:

Its a difficult project, what with the core diameter of the pull stud being only 9.85mm and some method to allow the chuck shaft to move axially and turn with the toolholder via a keyway or similar. The stroke will be severely limited, if the whole assembly is not fairly long. These sidelock spindles may have the answer to the finish of the bore and the screws could drive a slotted spindle. The sidelock holders do project downwards so a bit of headroom is lost. Your idea of a boring head shank is very good. They are unlikely to be through hardened and a nose cap could be used to hold it into the spindle, thus eliminating the troublesome drawbar. Think Myford spindle nose MT2 collets. Cut the top off it as necessary as the full length of the taper is not needed for axial drilling loads. You could use the threads originally destined for the boring head to screw on an unhardened piece that provides the sliding drive system. Was is Erikson who did a quickchange toolholding system for Bridgeports that used a cap to retain the tooling instead of a drawbar? In practice, stroke length is limited by lever ratio at the top end. 6:1 ratio, for instance needs lever to go 300mm for 50mm quill travel. Edited By DC31k on 02/11/2019 08:48:51 |

| old mart | 02/11/2019 17:38:06 |

| 4655 forum posts 304 photos | The quill will need 1 1/2" overlap when in the extended position, and this is added to whatever travel it has. This is why I thought one of those sidelock holders might be suitable. Of course, the seller does not include the length of the bore of any of them, so its pot luck. |

| Mark Davison 1 | 03/11/2019 19:03:34 |

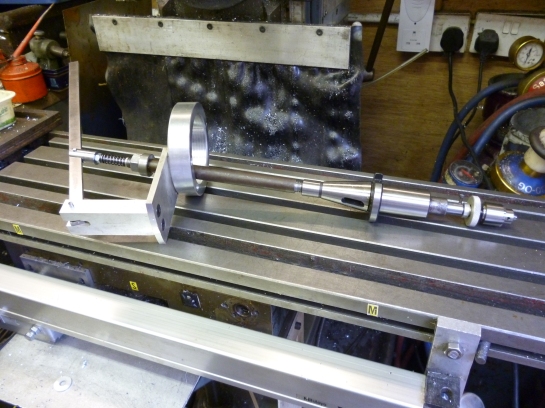

| 134 forum posts 38 photos |

|

| old mart | 03/11/2019 20:05:28 |

| 4655 forum posts 304 photos | Shame its a 40 size, I wonder how it is prevented from spinning round if you let go of the handle? It would be too long even if it was a 30 fitting. |

| old mart | 03/11/2019 20:40:46 |

| 4655 forum posts 304 photos | I have just found out that Gloucester tooling sell the iso30 boring head shank on its own. The thread is 1 1/2 X 18. They may be hard to drill and bore, but the thread would come in useful, as you might add more than one different length of extension to the shank for different quill travel requirements with bores matched. Edited By old mart on 03/11/2019 20:52:03 |

| Mark Davison 1 | 09/11/2019 09:38:15 |

| 134 forum posts 38 photos | Posted by DC31k on 31/10/2019 16:42:49:

Have a look at how Schaublin do their sensitive drilling attachment for the 30 taper spindle on the 13 mill. It locates on the spindle nose itself, like a big facemill would. Much easier to make than something that locates in the taper. You need to think of how the drive will be transmitted while still allowing sliding movement. Generally done with a key and keyway. A dog point grub screw into the 3MT adaptor could be used, but requires tapping a hard part. An accurate keyway is equally difficult in a hardened ER straight shank chuck. Copying the Schaublin design would allow you to put keyway in unhardened spindle nose adapter and use angle grinder to form a not-very-precise-over-wide slot in ER chuck and then JB Weld in a key (using the adapter to keep it aligned while it sets). See bottom left of page 6 here: https://drive.google.com/file/d/0Bxr59DtuJda_amx1V1dvNE8xVXM/view?usp=sharing (Anglo-Swiss Tools, Schaublin 13, French catalogue) for nose dimensions. Top right of page 12 for attachment complete. I have a drawing for all the Schaublin parts so if you PM me with contact details, I can send to you. I've finally got my head round what you meant when you said mount directly to the spindle nose. I still haven't got the mill (long story involving haulage company) so hadn't realised there are 4 threaded holes in the nose. The bit I still cant picture, even after study the drawing you sent (thankyou) is which way up the adapter mounts to the nose. I'd have assumed the ground face mates with the nose but the assembly drawing suggests it goes the other way, with he ground face down? |

| DC31k | 09/11/2019 13:55:13 |

| 1186 forum posts 11 photos | Posted by Mark Davison 1 on 09/11/2019 09:38:15:

The bit I still cant picture, even after study the drawing you sent (thankyou) is which way up the adapter mounts to the nose. I'd have assumed the ground face mates with the nose but the assembly drawing suggests it goes the other way, with he ground face down?

Sorry, I thought I had added a note on the email. The assembly drawing is incorrect, my fault. The ground part is up, the counterbored holes are down. To me, it is an easy part to reproduce, needing precision only on two concentric bores, one for the spindle nose, the other for the ER holder. |

| Mark Davison 1 | 10/11/2019 08:34:57 |

| 134 forum posts 38 photos | Sorry, you may have done, I jumped straight into the drawing! I'm going to go the 'Schaublin route' as you've suggested. Only drawback will be the time it takes to mount/unmount the nose plate and I think i can live with that. I'm just trying to decide if i buy a cheap ER20 straight shank collet chuck ( £13 +VAT from cutwel) and thread the rest of the shaft into that, or turn the whole thing from 1" EN8 bar that I already have. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in