Rev counter (Tachometer)

| John MC | 24/02/2019 17:38:56 |

464 forum posts 72 photos | I have recently been given a couple of electronic tacho's, cheap things that you will see for sale on Ebay. I want to use them on my milling machines. The question I have concerns the mounting of the magnet. Initially I wanted to mount it on the side of an aluminium disc, this being fixed to the driven pulley. Problem is that it would put the (Hall) sensor in a position that could vunerable to damage. I now want to mount the magnet on the periphery of the aluminium disc, this will move the sensor to a better position. My question is does it matte how the magnet is presented to the sensor? Thanks, John |

| JasonB | 24/02/2019 17:48:14 |

25215 forum posts 3105 photos 1 articles | Face to sensor and one face usually works better than the other Edited By JasonB on 24/02/2019 17:48:59 |

| The Novice Engineer | 24/02/2019 22:21:28 |

| 85 forum posts 72 photos | I have fitted one of the eB*y Tacho's to my Emco, although I used a smaller sensor than the one supplied [originally it was fitted to the emco Steppers]. The sensor is fitted into a housing that is stuck around the spindle with industrial double sided foam tape. I have placed the magnet side on to the sensor, its position is not ideal but it works. Steve |

| Plasma | 25/02/2019 07:35:51 |

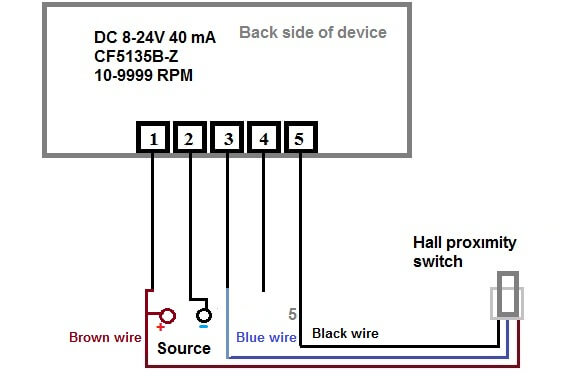

| 443 forum posts 1 photos | How do you wire these things up? I bought one and got a display and sensor in a box with no clue how to power it etc. I'm a complete electronics dunce I'm afraid. |

| JasonB | 25/02/2019 07:38:32 |

25215 forum posts 3105 photos 1 articles | Magnifying glass and you will see the colours of the sensor wires against the connector. Also google has images. +ve supply also goes to 1 and -ve to 2

Edited By JasonB on 25/02/2019 07:39:50 |

| Philip Rowe | 25/02/2019 11:23:10 |

| 248 forum posts 33 photos | I recently fitted one to my lathe and although it is recommended that the magnet face the sensor on its flat face I have found that it does work with the magnet on edge. It just means it needs to pass closer to the sensor, in my case around 4mm to guarantee reliable operation. Phil |

| Plasma | 25/02/2019 18:38:16 |

| 443 forum posts 1 photos | That's fantastic. Mine is for a wind speed station I built for my garden, rather than fitting to a machine. I will get it wired up now. Regards |

| John MC | 27/02/2019 09:08:57 |

464 forum posts 72 photos | Many thanks for the replies. I have tried the magnet in both orientations, both work but positioning is far more critical with the magnet on the periphery of a disc rather than the side. The device is quite slow to respond to speed changes, I guess thats reflected in the price! Also seems accurate compared with a hand held "Smiths" type tacho. One final question, does the "strength" of the magnet effect the performance of the device? John |

| John Haine | 27/02/2019 09:34:04 |

| 5563 forum posts 322 photos | These sensors use a Hall effect device to sense the magnetic field. The ones that give a "digital" on/off output, which the tachos generally use, are sensitive to the direction and strength of the field. The chips inside generally want a "north" pole (IIRC) to be presented to their top face and won't respond to a south pole. It's the direction of the field that's important, and they may respond if the magnet is presented in various orientations if there's a field component in the right direction. Ideally if using one of the common rare earth disc magnets try to mount the magnet and the sensor so they are "face to face" as the magnets are magnetised through their thickness. You will need to experiment to see which face is the right one to work your sensor. They will be slow to respond to speed changes because probably it counts pulses in a fixed time. So at 1 pulse per rev and 60 rpm, if you wanted to get a 1 rpm resolution you'd need to wait a minute to get 60 pulses. Alternatively they may measure the time between pulses and take the reciprocal, but even then they will average over a number of calculations which takes time, and of course the calculation takes some time too. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in