Help

Identify my new small Portass lathe

| peter blair | 20/03/2017 16:02:18 |

| 34 forum posts 25 photos |

|

| Neil Wyatt | 20/03/2017 16:32:44 |

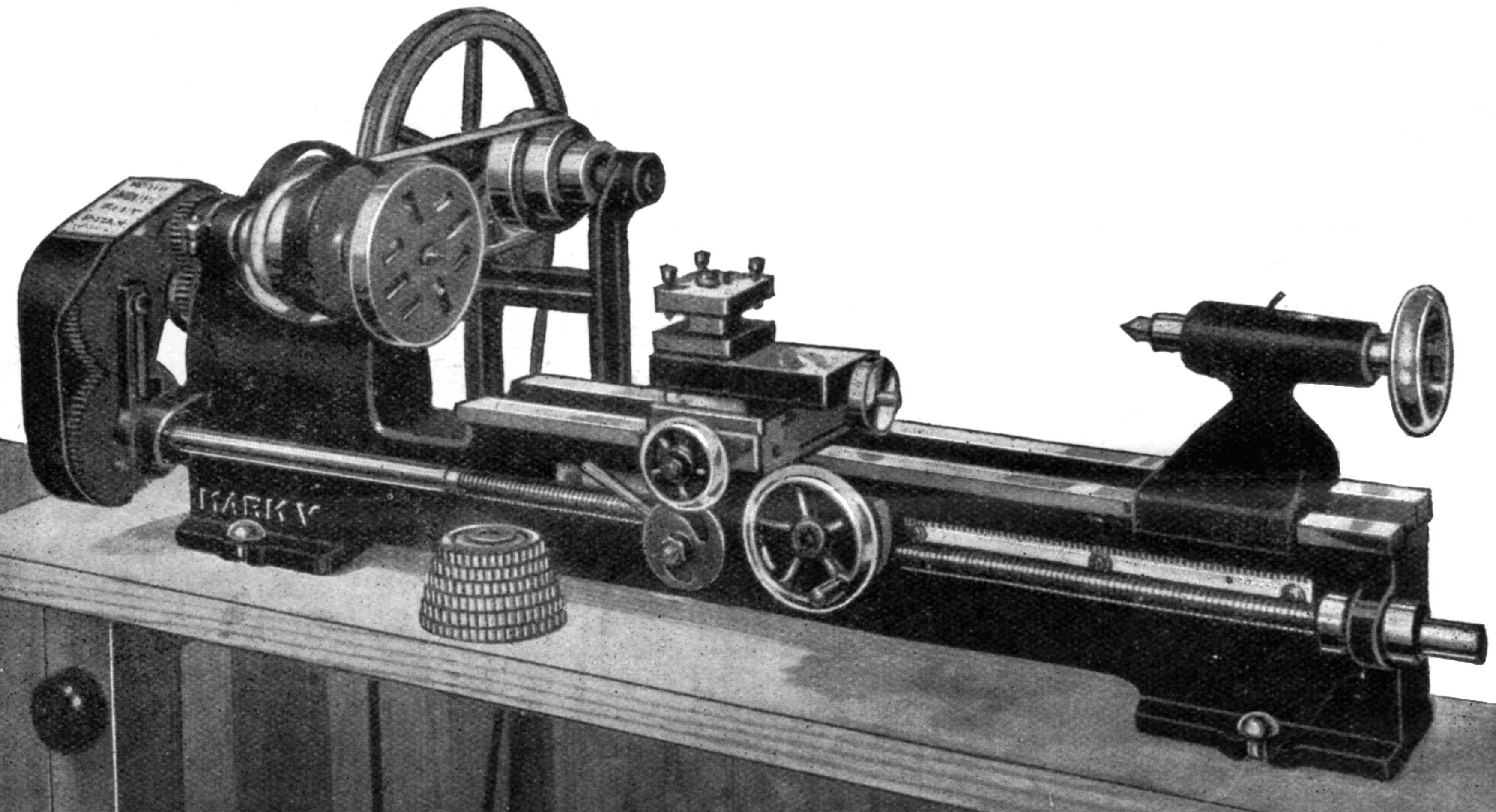

19226 forum posts 749 photos 86 articles | Have you looked here? I has much in common with the 3 1/2" centre height MkV but it appears to be too small and has the headstock and bed cast as one. <Edit> It seems the 3" Mk5 existed with both bolt on and cast in headstocks. I think this picture from HERE shows your lathe.

Neil Edited By Neil Wyatt on 20/03/2017 16:39:46 Edited By Neil Wyatt on 20/03/2017 17:15:24 |

| Speedy Builder5 | 20/03/2017 17:16:35 |

| 2878 forum posts 248 photos | the drive to the lead screw looks interesting being "belt fed" and a non positive drive. Looks like it could be a modification at some time. |

| Neil Wyatt | 20/03/2017 17:26:18 |

19226 forum posts 749 photos 86 articles | Posted by Speedy Builder5 on 20/03/2017 17:16:35:

the drive to the lead screw looks interesting being "belt fed" and a non positive drive. Looks like it could be a modification at some time. I agree, the lathe looks like it may have a couple of 'user modifications' Neil |

| Muzzer | 20/03/2017 17:28:45 |

2904 forum posts 448 photos | I've had a Portass model "S" for many years, although it hasn't had any action for the last 30 or more. However, it's clear that Portass made many different variants of several different models. Yours looks right posh, having a proper apron, half nuts, cross slide and relatively solid bed. Mine lacked them. I wouldn't spend too much time trying to "identify" it beyond what you have already. It's almost certainly got 1MT tapers in both the headstock and tailstock. The headstock bearings probably have split bronze bushes and if you overtighten the headstock clamp bolts when they become worn, you will fracture the casting (like mine), although they are repairable to some extent. I made loads of stuff on mine when I was a teenager. It can't take massive cuts obviously but if you can grind tools (or buy inserts) with lots of top rake, you will find it can put up a reasonable show. Screwcutting might be something you do for a bet, although amassing a sensible number of change gears might take a while. You could possibly 3D print some. Murray |

| Brian Wood | 20/03/2017 17:53:09 |

| 2742 forum posts 39 photos | Murray, |

| peter blair | 20/03/2017 22:20:55 |

| 34 forum posts 25 photos | Thanks gentlemen. A lot of useful information which is greatly appreciated! For sure the drive system has been modified and is quite interesting. Including a wooden three step fully on the motor.It does have a lot of similarities to the "S" but I haven't yet seen a photo that I could easily say "that's it! Murray if your memory is any good I do have one question that you might be able to help me with. next to the 3 step pulley on the main shaft is a gear. I assume if I had all the parts this would be use to produce threads. There are a number of holes in the right side of the gear and I can easily use at least one to 'lock' the spindle. Also in this gear is where my question comes form. There is a slot headed screw that seems somehow to push the gear away from the 3 step pulley. Can you remember what it was for?

|

| Michael Gilligan | 20/03/2017 22:59:22 |

23121 forum posts 1360 photos | Posted by Speedy Builder5 on 20/03/2017 17:16:35:

the drive to the lead screw looks interesting being "belt fed" and a non positive drive. ... . ... to a high reduction ratio worm & worm-wheel: A nice little modification for fine power-feed MichaelG. |

| Michael Gilligan | 20/03/2017 23:05:44 |

23121 forum posts 1360 photos | Posted by peter blair on 20/03/2017 22:20:55:

... next to the 3 step pulley on the main shaft is a gear. I assume if I had all the parts this would be use to produce threads. There are a number of holes in the right side of the gear and I can easily use at least one to 'lock' the spindle. Also in this gear is where my question comes form. There is a slot headed screw that seems somehow to push the gear away from the 3 step pulley. Can you remember what it was for? . That's part of the 'Back-Gear' arrangement, for slow speeds ... difficult to comprehend, because the other pair of gears are AWOL. MichaelG. . This page should explain, Peter: http://www.lathes.co.uk/latheparts/page4.html

Edited By Michael Gilligan on 20/03/2017 23:07:14 |

| peter blair | 20/03/2017 23:20:38 |

| 34 forum posts 25 photos | Thanks for the link Michael. I read it a couple of times and will need to re-read at least a couple more. The modification for the fine power feed is indeed very interesting driven by a rubber belt. It seems to work just fine but I haven't tried it while cutting. There is a gear at the back end of this drive system made of some sort of plastic which I assume was intended as a sacrificial gear. A couple of teeth were missing but I added some liquid weld and have refashioned the teeth. I doubt I will ever use it but at least it works now. Again, I can't thank you enough for your assistance. |

| Michael Gilligan | 20/03/2017 23:29:34 |

23121 forum posts 1360 photos | You're very welcome, Peter ... I think this short video will help https://m.youtube.com/watch?v=34xmgMHjmY0 MichaelG.

|

| peter blair | 21/03/2017 03:34:51 |

| 34 forum posts 25 photos |

|

| Neil Wyatt | 21/03/2017 08:29:47 |

19226 forum posts 749 photos 86 articles | Peter, I'm now 100% sure it's the 3" Mk5 as I linked to. For a start it's the only Portass with that 'hourglass' tailstock, there are cast in one headstock/bed versions and all the details of apron, handwheels, spindle/top.cross slide and back gear appear to agree. The only are where things are clearly different is the leadscrew which has a home made fine feed at one end and appears to have an odd handle fitted at the other. As these appear to be rare beasts, I suggest you contact [email protected] who will provide you with confirmation. Neil |

| peter blair | 22/03/2017 14:16:12 |

| 34 forum posts 25 photos | Niel, I agree I too am sure it is a 3" MK5 with modifications. Thanks for your help!! |

| Matthew Kennedy 1 | 01/05/2017 13:09:05 |

| 1 forum posts 2 photos | Peter, I have a George Adams GASC 3 x 12 lathe. I understand it is a Portass Mk 5 clone. Mine is very similar to yours but one size down. Yours appears to have had some interesting modifications.MIne was missing the tailstock gib. I have made a new one but the tail stock is best described as flexible. I would be interesting in knowing when mine was made.

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in