Checking runout

| John Milligan | 01/02/2016 14:44:50 |

| 59 forum posts 3 photos | finally at long last I have started to turn some metal on my lathe and need some advice. Have set up a dti on the lathe spindle nose and my 0.0005 indicator reads zero runout which I am well impressed with and also reads the same with a centre in the bore. Have a Pratt Burnerd tru grip 3 jaw chuck but there is a noticeable "wobble" on outer diameter when running under speed. So I chucked a piece of 3/8" BMS and using dti again got a 1 thou runout at the chuck face. I know that the BMS is not necessarily round but it looks like there is more movement than that on chuck diameter, is this normal and how do I go about checking actual runout? Regards John |

| Nick_G | 01/02/2016 14:49:48 |

1808 forum posts 744 photos | . Forget what the outside of the chuck is doing. (within reason) It's the center bit and what it is making your bar stock do that is important. A dead centre in the bore should show the same. ........... If it's a 'good one'

Nick Edited By Nick_G on 01/02/2016 14:51:41 |

| John Milligan | 01/02/2016 14:56:29 |

| 59 forum posts 3 photos | Yes the dead centre straight in the bore of the spindle was showing the same zero deviation, it just looked like the chuck was moving but there is no discernible movement when stationary. Will keep turning and see how it goes, thanks for reply, btw it's a myford super 7, John |

| MadMike | 01/02/2016 15:31:20 |

| 265 forum posts 4 photos | John as Nick says do not worry about the outside of the chuck body. To some degree ignore the measurement that you get from a dead centre fitted into the spindle, although it may be considered a starting point. Put a piece of steel in the 3 jaw chuck and face off the front face and then turn down the outer diameter. Then check the turned outer diameter that you have created. That will tell you the true runout of the machine itself. I would suggest at least a 1.5 inch diameter bar and a turned length of around 2 to 3 inches will give you a good reading. HTH.

|

| John Milligan | 01/02/2016 15:50:12 |

| 59 forum posts 3 photos | Thanks, next test tomorrow! John |

| Swarf, Mostly! | 01/02/2016 15:51:23 |

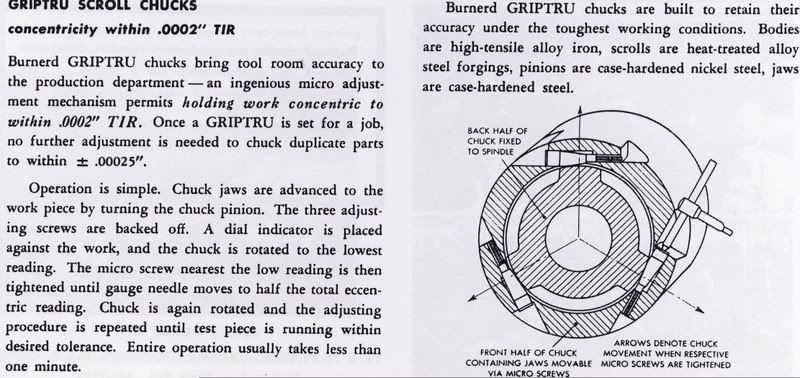

| 753 forum posts 80 photos | Hi there, John, You wrote 'Pratt Burnerd tru grip', did you mean 'Pratt Burnerd "Griptru"'? If so, the Griptru chuck is adjustable to eliminate run-out. I guess you have to perform the adjustment every time you change to a different diameter work-piece. The instructions should be on the web somewhere (probably lots of 'somewheres'! ). I'm sure there will be members here who can advise. Best regards, Swarf, Mostly! |

| MW | 01/02/2016 16:28:57 |

2052 forum posts 56 photos | If the chuck is attatched to a back plate its possible it hasnt quite sat in the register properly because of grit and swarf and can tighten up at a funny angle. this obviously doesnt apply if you have a camlock, which i guess may come with its own set of problems

Michael W Edited By Michael Walters on 01/02/2016 16:31:31 |

| Swarf, Mostly! | 01/02/2016 16:32:42 |

| 753 forum posts 80 photos | Hi there, again, John, I suggest that you have a look at this web-site: http://www.600uk.com/products/machine.asp?id=150 Best regards, Swarf, Mostly! Edited By Swarf, Mostly! on 01/02/2016 16:33:56 |

| John Milligan | 01/02/2016 18:21:35 |

| 59 forum posts 3 photos | Hi, thanks for replies, yes it's a grip tru and thanks for link so will look at that later. Have got Harold Hall's lathe work, a complete course to work through so hopefully by the end of that I will have a better idea! Didn't think I would forget so much in the thirty years I have been away from a lathe, lol John |

| John Milligan | 02/02/2016 10:15:45 |

| 59 forum posts 3 photos | So back out to shed to check machine today and thought I would start from beginning, checked run out of spindle inside and out, zero deviation, no vertical or horizontal movement of spindle either, checked threads etc on chuck and spindle all clean, don't have anything guaranteed round so checked with new centre drill and unused drill in chuck and runout at jaw face is 8 thou so I am of the assumption that jaws need adjusting as its a Pratt Burnerd Griptru? This is a new acquisition for me so I don't know the provenance of machine but everything looked well treated and cared for. Don't have a four jaw at present to use and funds won't stretch either. I have taken jaws out of chuck cleaned and reassembled checking they were in correct slots and noticed jaws 1 & 2 had slight play in slots but jaw 3 was nice and "tight" is this normal before I start looking further? Thanks John |

| Nick_G | 02/02/2016 10:56:44 |

1808 forum posts 744 photos | . Hi John, This is what I would do.- Others with more knowledge may have a different solution. But first let me say that that if you have a Griptru chuck and it's a good one it's a very enviable nice piece of kit. Get hold of a set of instructions for the chuck and become familiar with how it's adjustment works and how to do so. Have a good nosey at the jaw faces. (the bits that grip the bar) and check they are even and have not become 'bell mouthed' Then chuck up some known good round stock. Ground silver steel is good for this, but if you have none order a short length and use what you have for now. This will get you into the 'ball park' and make you familiar with the process for when the ground stuff arrives. I would order a short piece say 12 - 16mm dia. If possible concoct an adapter so that you can put your dial indicator into the tool post at centre height. That will give a good solid ref point. Take readings from as close to the chuck as you can. Then apply what you have learned from reading the instructions regarding adjustment. EDIT :- Also make sure the ALL mounting faces are totally clean. This includes perhaps even removing the chuck from it's adjustable backing plate to confirm this. Nick

Edited By Nick_G on 02/02/2016 11:03:45 |

| John Milligan | 02/02/2016 11:05:09 |

| 59 forum posts 3 photos | Hi Nick thanks for info, yes I looked at the link above and have asked them for an instruction download as I couldn't find one on the net. Have set up dti on toolpost already but will check on the jaws as you advise and will wait for the instructions before tinkering, cheers John |

| Nick_G | 02/02/2016 11:15:49 |

1808 forum posts 744 photos | . Try this to give to a general overview. |

| Hopper | 02/02/2016 11:24:57 |

7881 forum posts 397 photos | Those Griptrus are no good. Best you box it up and mail it to me.

|

| John Milligan | 02/02/2016 11:26:23 |

| 59 forum posts 3 photos | Thanks Nick, just checked my newly purchased (Christmas present) library of Workshop Practice Series books and there is one by Tubal Cain on work holding which details the Griptru chuck, awesome! John |

| John Milligan | 02/02/2016 11:27:28 |

| 59 forum posts 3 photos | Lol Hopper |

| John Milligan | 02/02/2016 15:20:57 |

| 59 forum posts 3 photos | Many thanks for all your advice, have now got it to within a thou runout so will see how it goes from here, John |

| Swarf, Mostly! | 02/02/2016 17:42:10 |

| 753 forum posts 80 photos | Hi there, John, I'm pleased to read that you've made progress. I wouldn't be surprised if, with a bit of practice, you'll be able to even improve on one thou. I endorse Nick_G's comment regarding the Griptru chucks - they seem to command about twice the price of a standard three jaw of the same size! So, if your workshop is a garden shed, take it ( i.e. the Griptru ) indoors each evening and stow it under the bed overnight!! Best regards, Swarf, Mostly! |

| John Milligan | 02/02/2016 18:22:39 |

| 59 forum posts 3 photos | Yes after releasing all the adjusting screws etc it felt as if they were getting easier so I assume it's not been adjusted in a while? Lol, workshop is in a new shed I have built but I don't think I will be taking chuck indoors overnight, my good wife already has to deal with loads of my junk there, cheers John |

| phil burley | 02/02/2016 19:57:25 |

45 forum posts 1 photos | but with all that effort why not just use a 4 jaw chuck . or is it that next time you use the griptru it will still be dead on ? regards Phil |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in