Best Way to Create These Radii

Complex-ish radii on Austin Seven fan pedestal

| martyn nutland | 27/07/2015 16:04:58 |

| 141 forum posts 10 photos | I wonder if someone could advise me on the best way to shape the complex radii on the part illustrated - this may not have worked, as I can't see any means of attaching the pix! It’s another of my Austin Seven foolishnesses, this one being the fan pedestal. Replicas have just come on the market but I thought making one would be a challenging project and I’ve bought the aluminium now! The trickiness is obvious and I really can’t afford concave (or is it ‘convex’, never sure whether you describe the shape of the cutter or the shape you want to make !) to form the spindle barrel. In any case, I don’t think those kind of cutters are really suitable for a vertical mill, lending themselves more to a horizontal machine. I think a large endmill followed by a bit of judicious filing ought to make a fair rendition of the big rebate that rises vertically through the base and finishes beneath the barrel. But I think the way forward for most of this, once the basic shape is milled out, is riffler files. Would that be a sensible approach? I did think it might be possible to cut the barrel radii on a rotary table. I.e. secure the work to the table and turn it against an endmill. The experts’ view on this would be helpful. As always very many thanks in advance for any thoughts. Martyn Edited By martyn nutland on 27/07/2015 16:09:58 Edited By martyn nutland on 27/07/2015 16:10:35 |

| JasonB | 27/07/2015 16:24:36 |

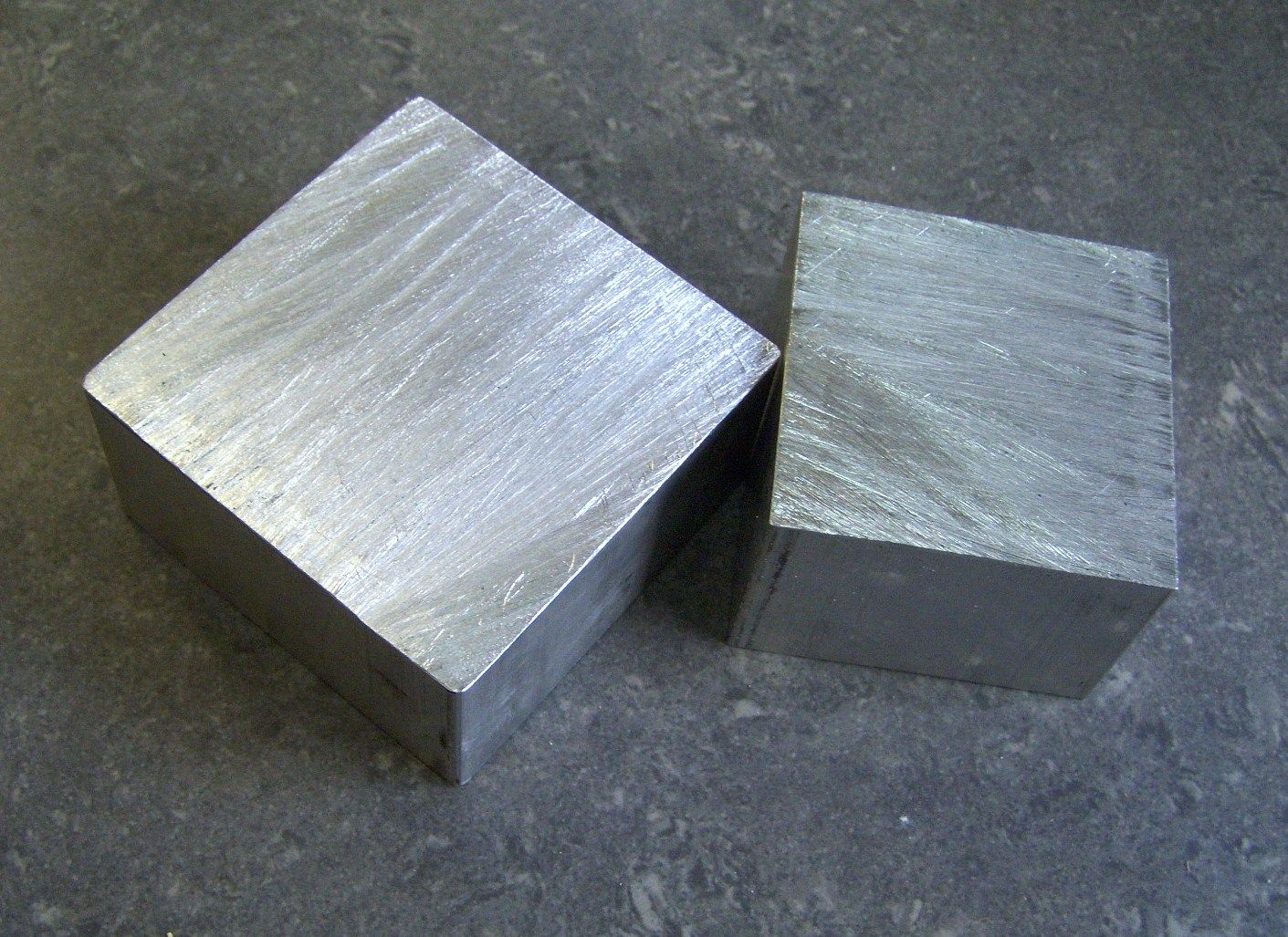

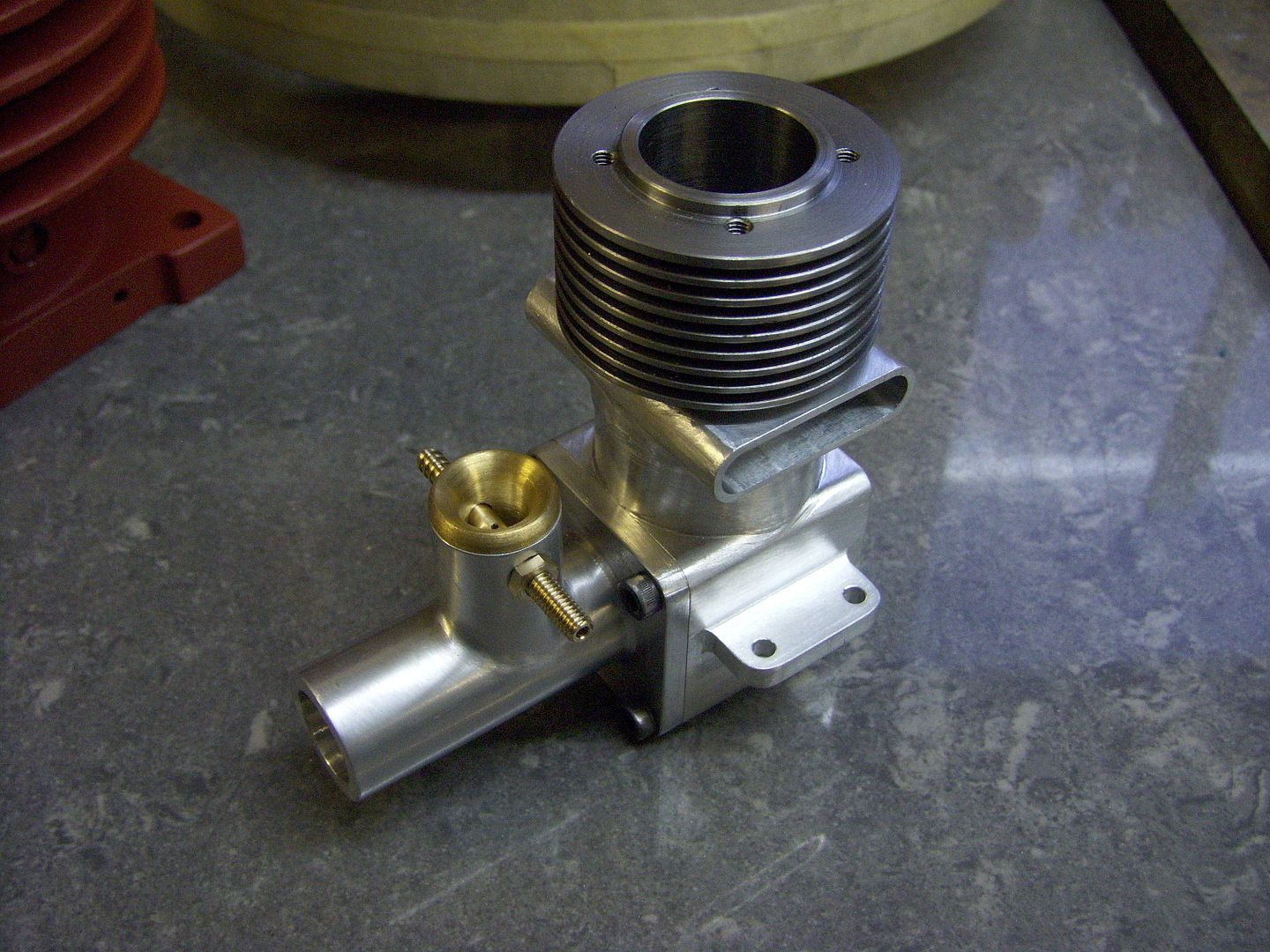

25215 forum posts 3105 photos 1 articles | Yes rotary table will be your best bet, take the majority off with a standard milling cutter and then finish with a ball or radius corner cutter. You will have to do some of it in stepps and then finally blend by filing. Put all the holes in first while its easy to hold and mark out on a rectangular block. It can be done, for example these two lumps

Became these

|

| martyn nutland | 28/07/2015 07:09:37 |

| 141 forum posts 10 photos |

MartynThanks Jacob. Beautiful pump. Hope I can get a result half as good.

|

| Marcus Bowman | 28/07/2015 09:54:59 |

| 196 forum posts 2 photos | Martyn,

This is probably no help, but I think you could produce all, or most, of that 3D shape using a small CNC vertical mill. Do you have dimensioned drawings (or even your own sketches with approximate sizes)?

You could certainly produce the curved section as you suggest, using an end mill and a rotary table, or using a boring head or boring bar, even though it is only a part-circle. The bores should be no problem either. The top curved sections might be possible using the bore holes as a pivot point, and the side of an end mill to get some or all of the curves. Then blend with files. Coarse files, well-chalked work best with aluminium, at least for removing bulk. As JasonB's post shows, you can get a really nice finish on aluminium. Mind you; if you are not too fussed about the exact detail of the outside of the shape (i.e. you don't need an exact replica) it may be possible to simplify the shape and make machining easier. Anything that eliminates the filing would be a bonus.

|

| martyn nutland | 28/07/2015 10:28:52 |

| 141 forum posts 10 photos |

Marcus Some very helpful thoughts there also for which I'm grateful. And I do have a factory-produced example to work from - to measure etc. And as you rightly say, it's not necessary to worry too much about and exact replica. It only needs to hold the fan spindle which is static. The blade is mounted on an eccentric (for adjusting the belt) on the end of the spindle and that's where the rotation takes place. But the reason the big rebate is there is to circumnavigate an oiler on the base on which the pedestal sits. So that shape is necessary. Thanks again. Martyn

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in