Marking out

How to mark out castings accurately

| Jesse Hancock 1 | 08/01/2015 13:11:02 |

| 314 forum posts | Hi Gang, I have a bit of a head ache when it comes to marking out castings, specificly the Sea Lion block at the fly wheel end. I don't yet own dro's which worries me since I have heard the accuracy on this engine is very important. Any solid ideas welcome. |

| JasonB | 08/01/2015 15:49:31 |

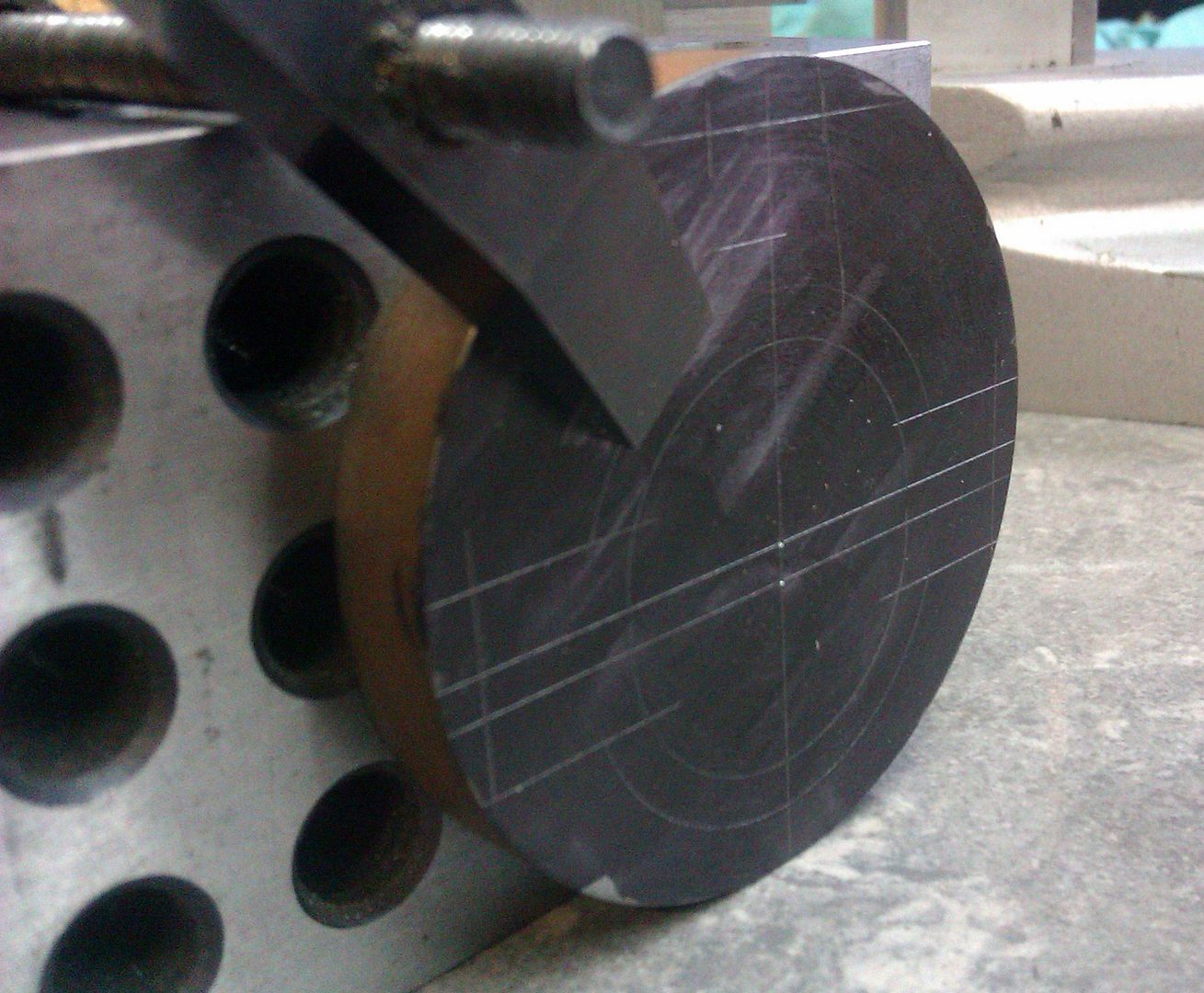

25215 forum posts 3105 photos 1 articles | Well as no body else has had a go. After initial checking of the casting to make sure you have enough metal where you need it shim it up true on the surface plate and mark a datum surface such as the top of block and one end. Machine the first surface using the same shims as you did when marking out, then with that newly machined surface on an angle plate do the end so they are at 90deg to each other. You can then use these two surfaces to mount the work while the bottom and other end are machined. You can now sit the bottom of the block squarely on the surface plate and have a nice flat rear to mark out all your horizontal lines with the height gauge. Next clamp the block to an angle plate same bottom surface to the plate and you can use the height gauge to mark all the points going the other way. Optical centre punch where the lines cross and then when you go back to machine the part you have accurate punch marks to locate a centre finder in. This is another way with small parts clamp them to a 1-2-3 block so you can mark lines going one way, then stand the block on end to do the others

|

| Jesse Hancock 1 | 08/01/2015 21:54:56 |

| 314 forum posts | Thanks Jason I'll give it a whirl. Also you have made me realise the short commings I have in my marking out tool box. Hmmm I'll see what's about out there. Jesse |

| Bazyle | 09/01/2015 13:29:42 |

6956 forum posts 229 photos | If you have a problem with getting a knobly casting to sit still you could glue it to a flat plate with hot melt glue (suggested on here I think recently for machining small parts), or hold it in a big dollop of plasticine. We used to have industrial sized 2lb packs of placticene as a stores item in the macaroni factory I assume for this kind of thing. Doesn't help for machining though. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in