Thompstone Engine

A thread to accompany the build series in ME

| JasonB | 08/11/2022 19:04:09 |

25215 forum posts 3105 photos 1 articles | John the JB Weld was an option for those that may not have the facility to silver solder but yes it is possible to silver solder CI, usually needs a pre heat to bring the carbon to the surface which is then cleaned with a fine wire brush before heating again and soldering. Although my own engines that have been bonded with JBW have only been run on air others here such as Ramon have built engines that do get steamed and have had no problems. Ramon has also tested joints to several 100psi both hot and cold and they hold up well. Do make sure to use the "original formula" (red and black tubes) not the rapid or marine as they don't have such a high temperature rating |

| James Smith 24 | 08/11/2022 21:01:11 |

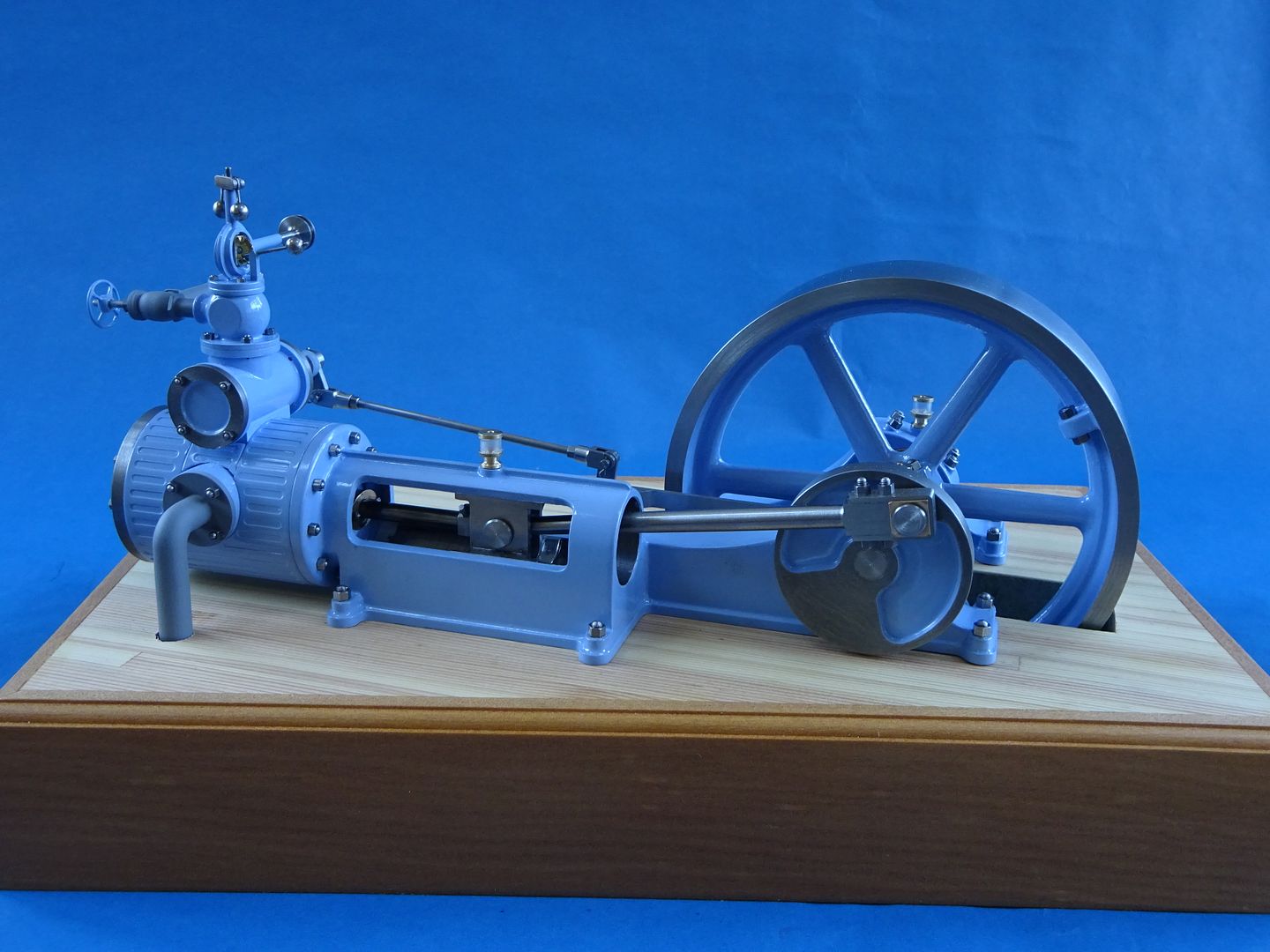

| 8 forum posts 5 photos | Jason, Thanks for the comprehensive reply, I had drilled the holes 2mm as the drawing so will probably go with the M2 studs with a nut at each end. Below are a couple of pictures of where I am up to, I am not totally happy with some of the parts so may yet remake but will see. It has been an interesting project and have learned a great deal from it. James |

| John Rutzen | 08/11/2022 21:01:39 |

| 411 forum posts 22 photos | Thanks Jason, that's interesting to consider as an option. The design of the joint would also obviously have a lot to do with it. I've only ever used it to make fillets when I fabricated the flywheel for my Rumely tractor. |

| JasonB | 09/11/2022 06:50:42 |

25215 forum posts 3105 photos 1 articles | That's looking good James and you don't look to have too many bits left to make. |

| James Smith 24 | 11/02/2023 16:42:02 |

| 8 forum posts 5 photos | Finally completed my version of the engine so thought I would upload a couple of photos. I repositioned the steam inlet so I could recess the valve cover.

|

| JasonB | 11/02/2023 18:34:13 |

25215 forum posts 3105 photos 1 articles | That looks to have turned out rather well, the slightly larger flywheel does not look out of place and the colour is nice and subtle plus it makes a change from the usual dark greens and crimsons. How does it run? |

| James Smith 24 | 12/02/2023 10:37:27 |

| 8 forum posts 5 photos | Thanks Jason, I was inspired by your use of muted colours for my choice. The flywheel was not ideal, but what I could get hold of reasonably easily at the time, I don't think it looks too bad, but when I compare with yours I do like the slimmer smaller design. It runs okay, though have only been able to try on air. I have to decide on a next project now ! |

| Dave Wootton | 12/02/2023 13:22:21 |

| 505 forum posts 99 photos | Nice work James a very good job and the flywheel looks fine to me, the grey colour suits it well. good luck with the next project i'm sure it will turn out as well as this one has. Dave Edited By Dave Wootton on 12/02/2023 13:23:41 |

| paul rayner | 13/02/2023 18:46:21 |

| 187 forum posts 46 photos | Hi James Love the colour. As it happens I've just pulled out my bits this weekend, hopefully I should get some time over the next couple of weeks to do a bit more. Paul |

| geoff walker 1 | 14/02/2023 11:06:37 |

| 521 forum posts 217 photos | Hi James, Just add my congrats, very nice indeed and for me one Jason's best designs. I too love the colour, it looks like my favourite, Halfords industry grey? Geoff |

| JasonB | 14/02/2023 16:32:46 |

25215 forum posts 3105 photos 1 articles | I must get round to writing up another engine for the mag, this vertical is the most likely candidate. My usual 24mm bore and again with a soldered cylinder though a little simpler than the Thompstone. The standard is also silver soldered from 3 bits of steel, base is a "box" from screwed and JBWelded aluminium. It's a similar size to a Stuart No7 (before it became the 7A) and materials would be about 1/3rd the cost of a Stuart casting set, few quid more if you wanted to use a spoked flywheel casting.

|

| paul rayner | 14/02/2023 18:39:31 |

| 187 forum posts 46 photos | oooh looks nice, another one to add to my retirement list! have you any plans to do a tangye or twin victoria style? or maybe even a bottle engine or am I asking too much

Edited By paul rayner on 14/02/2023 18:41:06 |

| JasonB | 14/02/2023 19:09:15 |

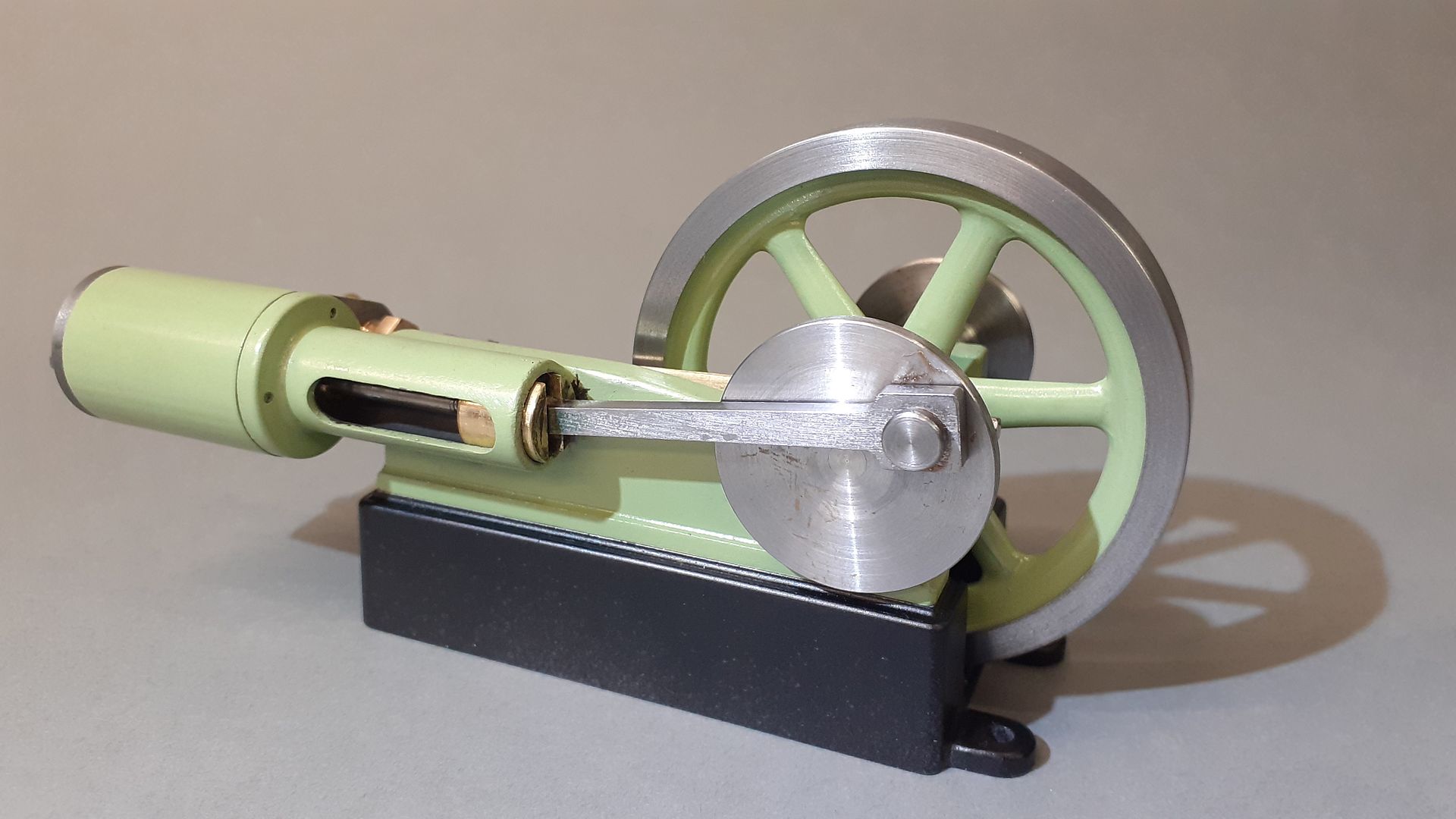

25215 forum posts 3105 photos 1 articles | I suppose my Filer & Stow is not too far removed from the design usually associated with "Tangye" with a slightly different trunk guide.

Or for a simple quick project my version of the Stuart "One One" is the same sort of layout. Bothe could easily be built as back to back pairs for that "Double Tangye" look

I do have quite a few images and details of the Tangye "Colonial" engine which is one on the to do list but not near the top

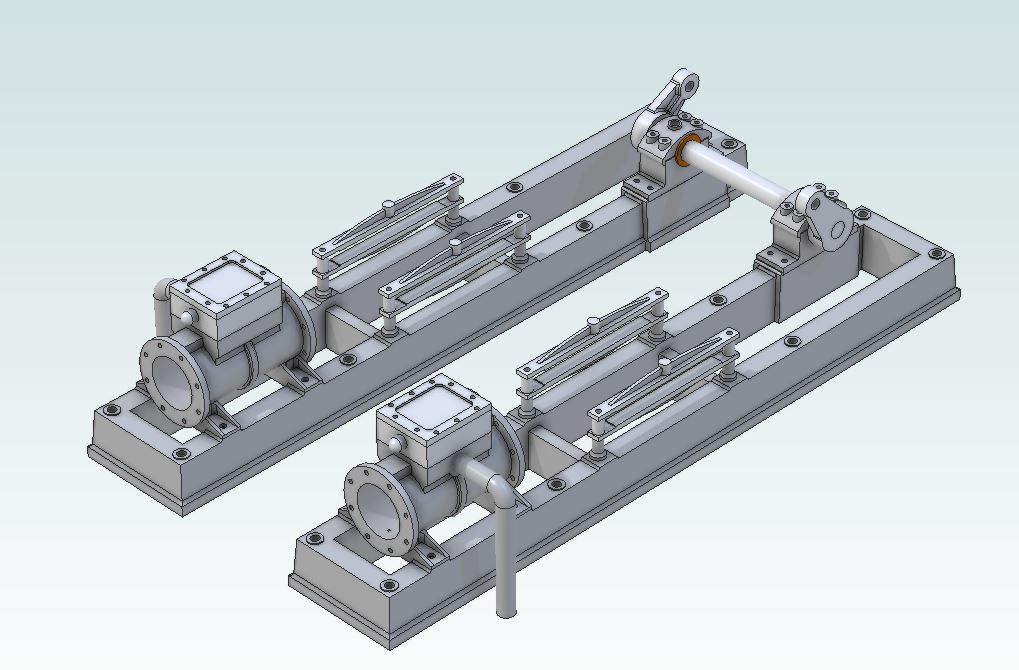

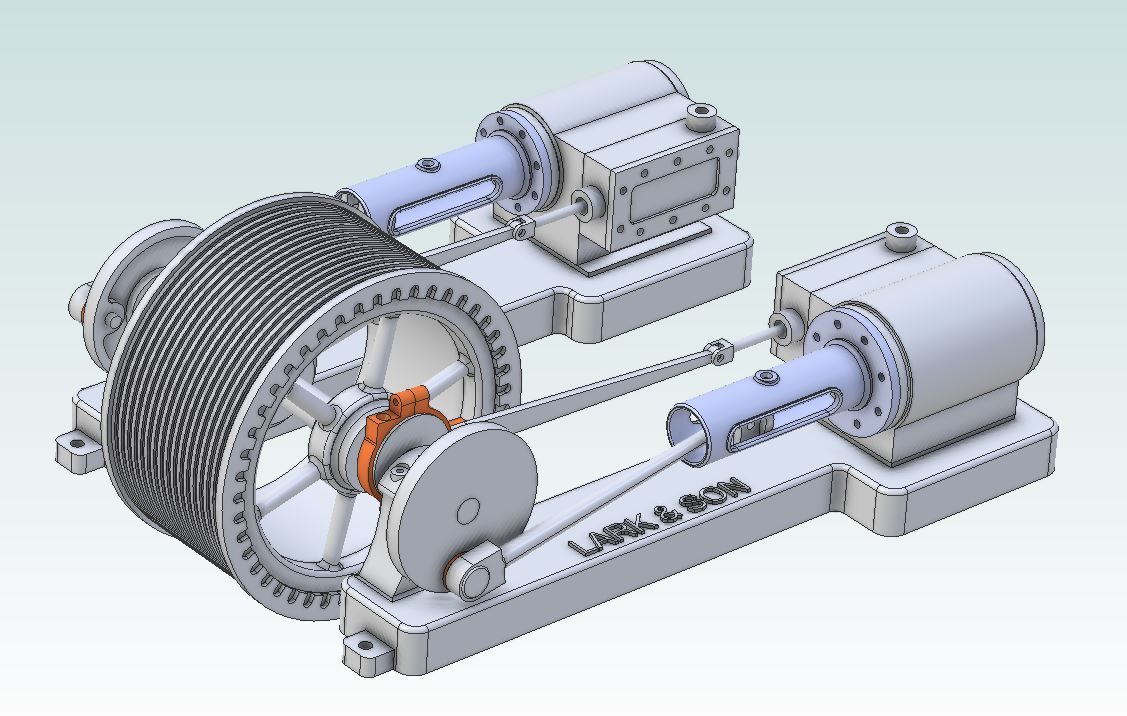

I did draw up a Victoria Look Alike to be made from barstock but ended up making one from a Casting Set with a few alterations, again could be made as a twin fairly easily just a case of pressing "mirror" on the CAD file Or for a slightly simpler project a reworking of the Clarkson as the Lark and Son cross compound which could either be done by modifying the Clarkson castings or better still cut from solid

Bottle engines are nice and something to think about, should be interesting carving the bottle from solid. Probably have to split it in half horizontally so the insides can be hollowed out and then after joining cut the pockets in each side. The James Begg one that Anthony Mount designed was a nice engine but not available now that Cotswold Models are no more and I'm not so keen on the PM Research one.

|

| paul rayner | 14/02/2023 22:31:54 |

| 187 forum posts 46 photos | Hi Jason I know what you mean about the PM bottle, It just doesn't just look right, maybe a bit skinny? I do have 1 set of them clarkson castings squirreled away, Blackgates are stocking all clarksons castings and plans if anybody is interested. I've never heard of Lark & Son. looks a nice engine. I will have to google it. Paul |

| James Smith 24 | 14/02/2023 22:50:03 |

| 8 forum posts 5 photos | Thanks all for the positive feedback, much appreciated. The colour is Rustoleum Sage Green, was about the only colour the local hardware shop had that came close to what I was looking for, and now its on I do like it. I have plenty left in the can so I can guess what colour the next one will be ! Thanks to Jason for the series, it was a good build with plenty of learning along the way, so I think I have gained a lot of experience during the build.

|

| paul rayner | 06/07/2023 17:17:23 |

| 187 forum posts 46 photos | Hi all, Just a quick one i'm back on the Thompstone decided to splash out and buy some PB for the cylinder rather than use CA, Stupid question but on the drawings on page 491 the valve block is 22mm wide but the steam chest is 20 mm wide, I presume this is a printing error and should read 20mm? also the text states on page 562 tap the steam chest M4 but the drawings state M5, I presume the M5 is correct? as the valve nut is also M5 & M4 would make it rather thin walled. Sorry for daft questions, but I just want to clarify before I cock something up. thanks for all reply"s in advance Paul |

| JasonB | 06/07/2023 18:47:30 |

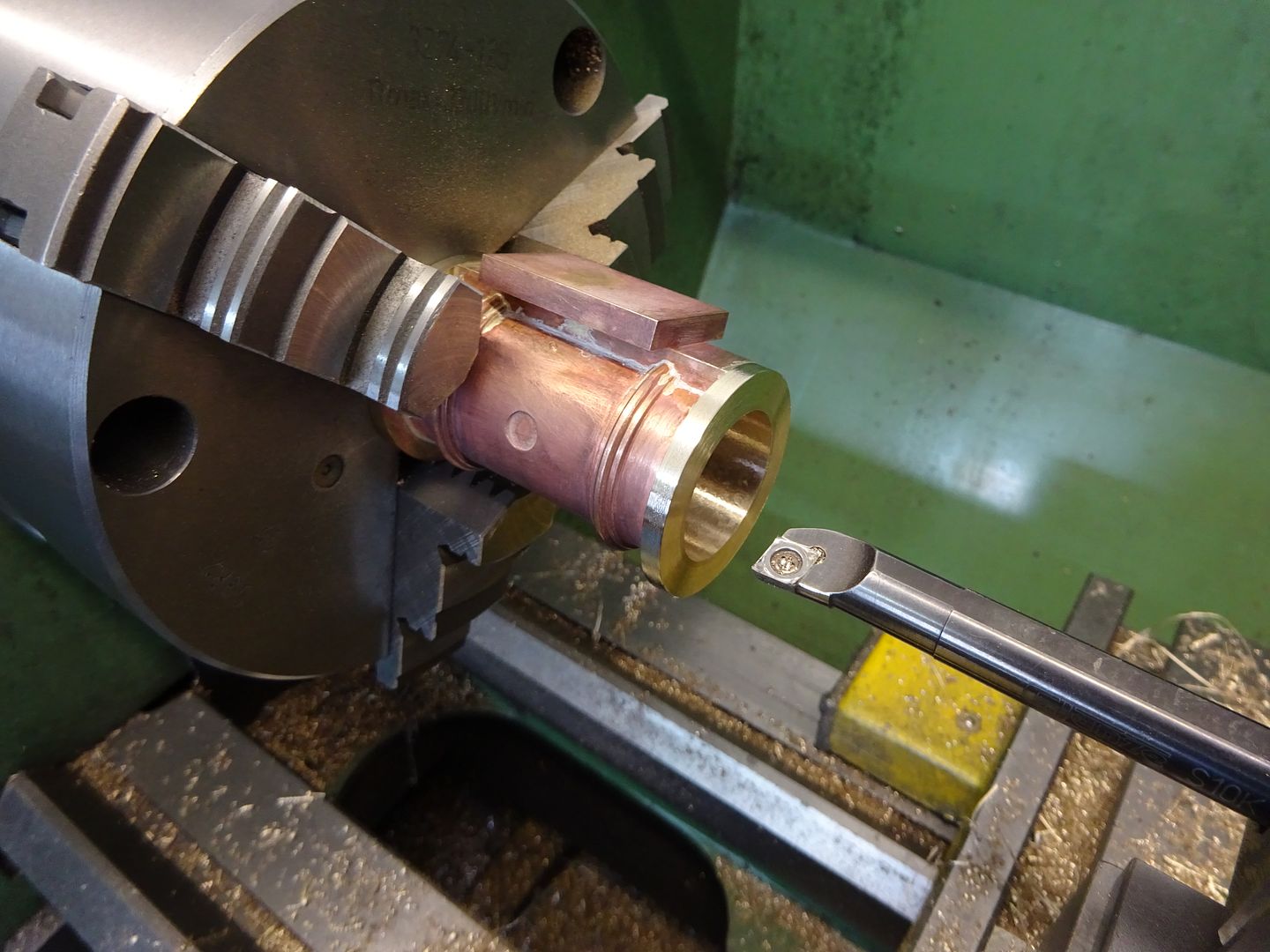

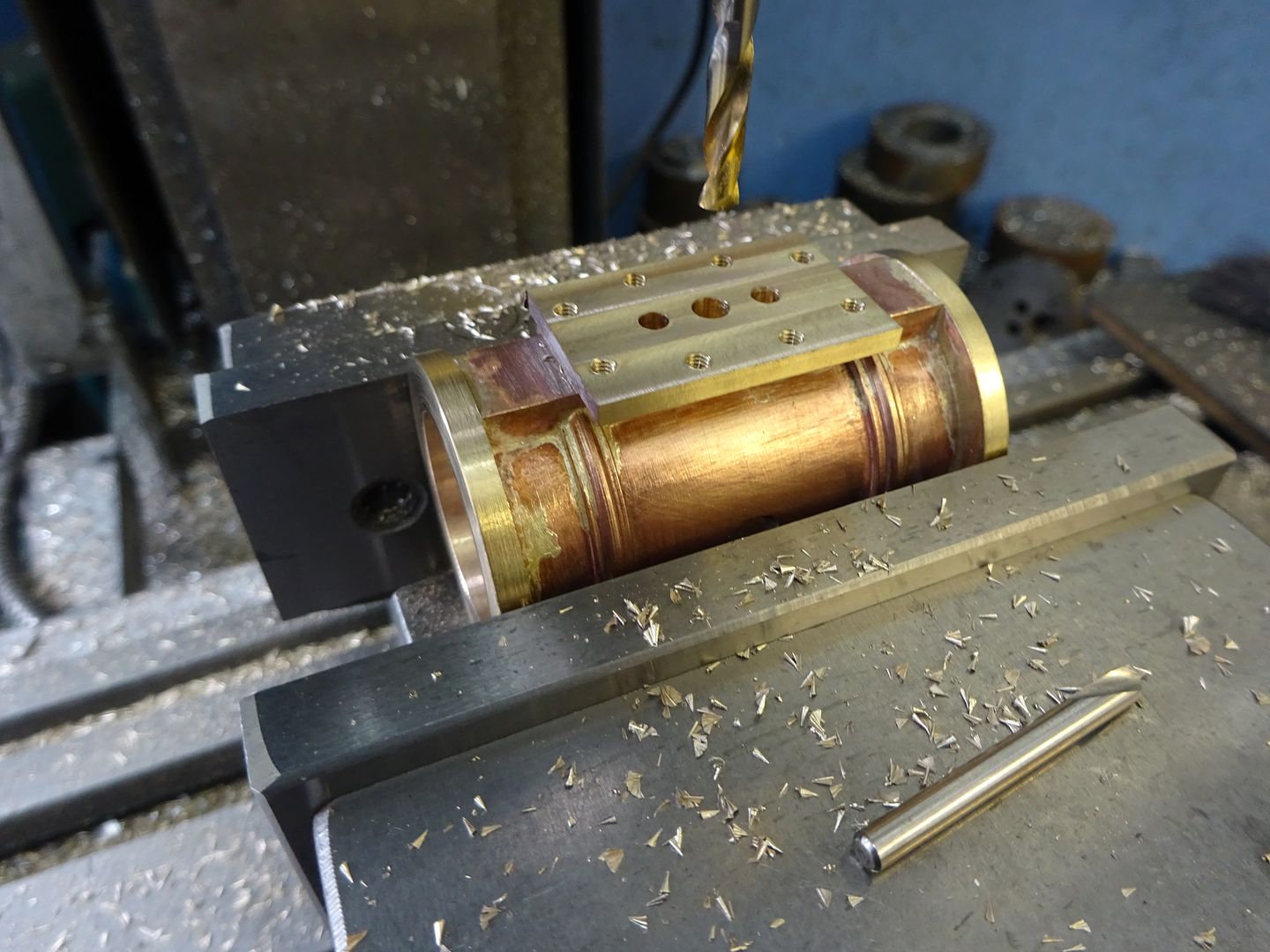

25215 forum posts 3105 photos 1 articles | Several of the components that make up the cylinder are shown with a machining allowance on my drawing No2 so that they can be taken down to finished size after they have all been soldered together as drawing No3. There is 1mm down each side of the valve block to come off and also 1mm off it's face to bring it down to 2,5mm thick from the individual parts 3.5mm thickness. Similar with the two "washers" that make up the end flanges which are over thickness and over diameter, If you look at thes ecouple of photos you can see th ebrighter freshley machined surfacs compared with the darker ones of the pickled assembly.

Text is wrong, the chest gland hole should be tapped M5, preferably M5 x 0.5 metric fine but 0.8mm pitch metric coarse would do J |

| paul rayner | 06/07/2023 20:30:47 |

| 187 forum posts 46 photos | Cheers Jason, I've just read about machining the cylinder and I get it now. I new it would be a stupid question! having said that, I have not machined the cylinder yet as i've a poorly lathe (waiting for parts). Just thought I would do what I could on the mill while I have the chance. Thank you Paul |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in