Boxford as a wood lathe?

| Yngvar F | 05/07/2016 21:58:07 |

| 75 forum posts 54 photos |

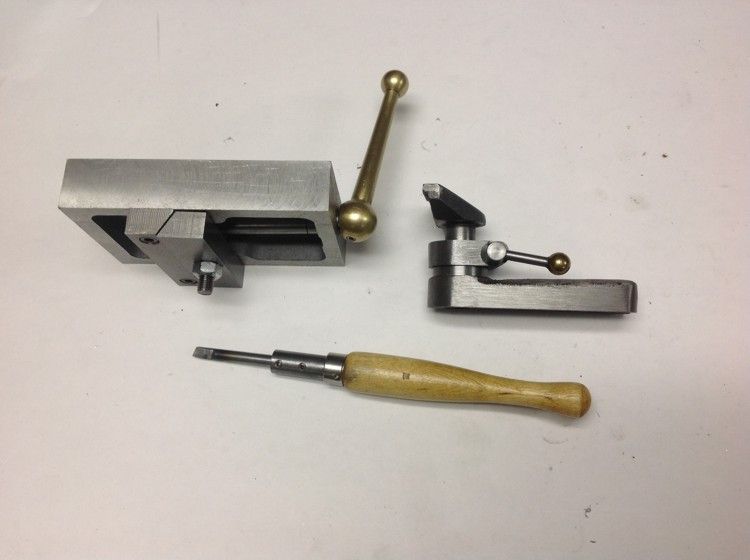

Don't know if your lathe has the old style south bend/boxford compound, If it does adapting a woodturning toolrest works a treat

Edited By Yngvar F on 05/07/2016 21:58:55 Edited By Yngvar F on 05/07/2016 22:00:04 |

| MW | 05/07/2016 23:18:46 |

2052 forum posts 56 photos | Posted by Neil Wyatt on 05/07/2016 19:51:47:

One of these should not break the bank and allow you to keep the Boxford. www.machinemart.co.uk/p/clarke-cwl325v-13inch-mini-wood-lathe-with-ele/ Neil Good choice, the 1/5hp motor is probably ok for pen making. I've never had a problem with the quality. Always found it was pretty decent. Michael W |

| peak4 | 06/07/2016 02:14:50 |

2207 forum posts 210 photos | Posted by Neil Wyatt on 05/07/2016 19:51:47:

One of these should not break the bank and allow you to keep the Boxford. www.machinemart.co.uk/p/clarke-cwl325v-13inch-mini-wood-lathe-with-ele/ Neil Not only that, it's a Clarke, so bide your time and wait for one of the VAT free offers.

|

| Marcus Bowman | 06/07/2016 08:09:51 |

| 196 forum posts 2 photos | No-one has mentioned decent dust extraction as being a solution to most of the problems of dust and debris. A powerful extractor designed for wood dust transforms the experience by removing much (but not quite all) of the dust. The challenge is in arranging the nozzel near enought eh surface of the work, and making it traverse with the toolpost/carriage. I use an 2HP Axminster unit which operates on the "vacuum" principle. I have also used an earlier unit based on lower suction at the nozzle, but intaking larger volumes of air. The vacuum does the job for my kind of work, but must have a small nozzle positioned close to the work surface. That just leaves a bit of dust, which, while requiring clean up is not a great problem. Cleaning the bed of the usual oily film before turning wood is essential. Cleanu up of chuck etc is important, but no worse than when turning cast iron etc. The comments on speed etc are valid, especially for small diameter work. A lathe is a lathe, and I never could really understand how a woodturner could claim a wood lathe was better for tunring wood. To me (and I own a wood turning lathe too) the engineer's lathe has proper precise control of carriage and cross-slide, meaning one can turn wood precisely parallel and to size. Sure; it shrinks and moves later, but that's the wood, not the lathe. My wood lathe says under the bench, out of the way.

Boxford made two wood turning tool rests(short one and long one) to fit the old bench lathes (AUD, BUD etc) but ther are designed to fit the old-style rest-holding arrangements which use a tapered plug. It is easy to make a simple adapter to allow those rests to fit onto a plain surface or a tee slot etc. I suggest second-hand dealers (see G & M Tools, for example). It is also relatively easy to adapt other rests, and I often use a rest from a Record wood lathe to give me an extended rest which sits out a distance from the normal rest position, for larger jobs. One other word of caution. It is worth pointing out the dangers of wood dust from some species of trees, as well as the general danger to the respiratory system from small wood dust particles. I have found this is not to be underestimated. The same is true for other materials, of course, but the species-related dangers are both real and well documented. Real woodworkers cheerfully ignore dust masks, goggles and ear muffs - but they are all dead, blind or deaf, so I guess they knew best. Marcus |

| Hopper | 06/07/2016 12:28:07 |

7881 forum posts 397 photos | Or you could make yourself the Rolls Royce of turning rests, the GH Thomas Quick Action Hand Rest. Advantages include that it mounts direct to the bed of the lathe, not the carriage. So the carriage, cross slide, top slide etc etc can be tucked away at the far end of the bed, away from the worst of the sawdust. Disadvantages, as with much of GHT's stuff, include that it is a compex way of doing a simple job. He says himself that some would be as happy with a rest made from a bolt and a piece of angle iron (Guilty as charged, yer 'Onor.) Drawings are in his book ME's Workshop Manual, or kits are I think available from Hemingway.

|

| MW | 06/07/2016 12:38:04 |

2052 forum posts 56 photos | "A lathe is a lathe, and I never could really understand how a woodturner could claim a wood lathe was better for tunring wood. To me (and I own a wood turning lathe too) the engineer's lathe has proper precise control of carriage and cross-slide, meaning one can turn wood precisely parallel and to size. Sure; it shrinks and moves later, but that's the wood, not the lathe. My wood lathe says under the bench, out of the way."

The traditional woodlathe which the metal lathe grew out of, was a traditional craft where most of the work would be carried out freehand. There wasn't a great deal of tolerancing so therefore things were simply made to fit if they needed to be. You have to learn the ability to turn freehand and its not something you can pick up overnight if you want to work well and accurately. Much like filing really. Michael W |

| John McNamara | 06/07/2016 13:19:54 |

1377 forum posts 133 photos | Having used a metal lathe a couple of times to turn wood and metal freehand with a simple rest only no tool slides, one thing was made clear right from the start, the turning tool (Must) have a long handle, otherwise there is a risk of the tool being grabbed out of your hand. Where the tool ends up is will be down to luck, hopefully it will not involve putting your hands or other parts of the body at risk. There are plenty of videos on the net like this one to see how it is done, **LINK** or just search for wood turning videos. Note the long handled tools and the the way the tool is gripped firmly with both hands, and for heavier work under the arm as well. The tool has to be controlled at all times. One project was was to make a decorative spindle out of mild steel to match a broken antique part. The tool was a piece of high speed steel. until I fitted a long and sturdy handle it was uncontrollable. The tool wanted to dig in and wrench itself out of my hands. Once you get the hang of it freehand decorative turning is very enjoyable, without the limitations of cross slide and top slide XY travels you are able to create on the fly without constraint. Invigorating! Regards Edited By John McNamara on 06/07/2016 13:22:23 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in