Member postings for geoff walker 1

Here is a list of all the postings geoff walker 1 has made in our forums. Click on a thread name to jump to the thread.

| Thread: ME vertical boiler |

| 19/01/2018 18:45:29 |

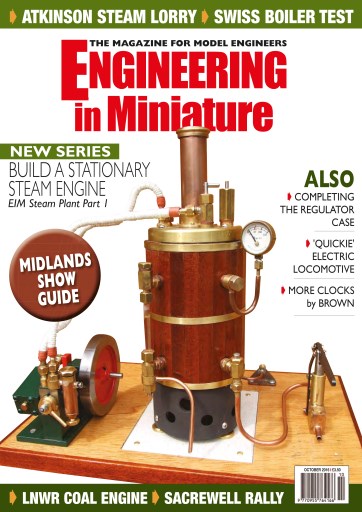

Anyone know if this is going to be a duplicate of the EiM vertical steam plant?

Looks very much like the same boiler Jason. Have you got the eim issue numbers? I may need them I have just bought today M.E. 4578 today eagerly anticipating part 2 of the M.E. boiler article. I can't believe what I'm reading, preparing blanks and datum locations, understanding working drawings, axis conventions and locations and checking a machine head and vice alignment. Absolutely nothing to make and it looks very much like part 3 will have nothing to make as well. In part 3, quote, we will look at the bill of materials you will need. Three parts, well two at least and nothing to make? Do me a favour!!! Rant over |

| 15/01/2018 19:43:20 |

Perhaps I've missed something but I have to admit to being a bit perplexed by this series. Why would a beginner be encouraged to equip themselevs with a milling machine (not necessarily a small investment) in order to build a simple boiler? I have to say that the use of milling machine puzzled me. That's not a criticism just an observation and I look forward to part 2 in issue 4578. As I have no milling machine I will have to improvise. I assume the use of a rotary table is for setting out the hole positions in the top flange plate? In due course all will be revealed. Geoff |

| 15/01/2018 18:40:53 |

Thanks Frances, Jason. 4578 is out on Friday, so not long to wait. geoff

|

| 15/01/2018 18:23:35 |

Hi All Model engineer issue 4576 has part one of a project by Martin Gearing on a vertical boiler for beginners. Can anyone tell me if this is continued in issue 4577? I've searched online for information but am unable to find anything. Called in W.H. Smith at the weekend but they had sold out. I will order a copy online but only if part two of the boiler project is featured. cheers geoff |

| Thread: bolton steam museum |

| 22/12/2017 16:03:42 |

Hi All Last live steam days of the year next week 28th. and 29th. 10 till 4. Free entrance, free parking and inside a cornucopia of delights for all steam enthusiasts. Geoff.

|

| Thread: 1947 Jepson engine |

| 21/12/2017 13:31:04 |

Hi Ian and ndiy, Thanks for your comments. Sold the adept Ian, big mistake, I now have small indoor model room where I do much of my assembly work. The adept would have been perfect in there ideal for some "little bits". The jepson is now on youtube, not complete, an early test run which went quite well. It's leaking here and there and needs a bigger compressor than the airbrush one being used. If I could keep the pressure up this engine would be a real high speed "fizzer" You tube "1947 jepson vertical marine steam engine". Sorry not worked out how to upload videos, I'm rather hoping Jason or Neil will do the honours and add it to this post. cheers geoff Edited By JasonB on 21/12/2017 13:36:26 |

| Thread: Building Stuart Victoria |

| 21/12/2017 13:17:34 |

Yes, nice work Steve. I like this engine a lot, seriously considering forking out for a kit. Smooth, long slow stroke, lovely. Can you tell me something about the port sizes, valve size, lap, lead, eccentric throw etc. Just curious really, I'm a tyro builder trying to develop a deeper understanding of valve dimensions and settings. Lovely engine, I'm starting to drool!!! Geoff |

| Thread: 1947 Jepson engine |

| 19/12/2017 17:52:39 |

Neil, A fair point. When I bought my Myford/drummond M type I spent 6 years doing nothing except renovate and make parts/accessories for it plus two other drummond M's a flatbed drummond and ......... a super adept ( now you didn't know that did you?). This year I decided it was time to make something, the whittaker firefly 46 and now my second the jepson engine which is nearing completion. I now consider myself to be a model engineer but still a tyro. I had the jepson running today and I'm pleased to say it ran very well. The only problem is keeping it going for an extended period. I ran it off the airbrush compressor which is fine for a small oscillator but the jepson gulps in air like a drowning man rising out of the sea. 15 seconds and the pressure has dropped and the tank has drained. I need a bigger compressor! geoff |

| Thread: "It" comes to life again |

| 18/12/2017 11:40:07 |

I do want to apologize if I sound crabby. You don't sound crabby to me Dean, very focused and committed maybe but not crabby, I find your work fascinating,I really do and I know from experience how difficult it it is to master the techniques that you are using with such apparent ease. Speed bumps? We call 'em sleeping policemen this side of the pond. best wishes geoff

|

| Thread: 1947 Jepson engine |

| 18/12/2017 11:15:01 |

With tongue in cheek may I ask, do the moderators of this site have a duty of care to other users? I speak mainly for old gits like myself. When I started this engine nobody informed me that I would have to make tiny components like these which with failing eyesight and increasingly creaky finger joints has at times been a somewhat onerous task. Hmmmm. Having said that I'm getting there. The potts set up has been "just the job" for these mini parts. I'm planning a first test run (air test) on Christmas day as a present to myself. I shall slip away away from the festivities to the haven of the modelling room probably with my young grandson Matty in close attendance. Speaking of Christmas could I offer my best wishes to everyone all over the world, hope you all have a good 'un with family and friends. Must confess I still enjoy having the tribe visit, everybody around the big table, party hats donned. The mind is forever young even if the eyesight and joints 'aint. Geoff

|

| Thread: Live Steam Loco Questions |

| 15/12/2017 17:14:10 |

I have very little knowledge of live steam locomotives, never made one and it's highly unlikely at my age that I ever will. What I can say to help Stewart is that my local model engineering society ( Warrington ) attends our local carnival every year and sets up a portable track about 40 yards long. For a small charge around 10 - 12 people can ride on open carriages behind the driver of a small 5" gauge locomotive. The locomotive in question is a "Simplex" which I believe is very popular club locomotive. Now if it can pull ( and push ) all them people Stewart it will handle a big lad like you, no problem. Now whether Simplex is simple to make I really don't know but I would suggest it would make a good challenge for somebody with real enthusiasm and a determination to see the job through. What you are considering Stewart may indeed take over your life but if you are really up for it and you have deep pockets, it aint cheap to make one, my guess would somewhere around £2000 just for the materials, go for it you'll love it. geoff |

| Thread: TV tonight |

| 13/12/2017 13:06:47 |

ITV 3 tonight at 11.00 p.m. An appropriate adult. The story of Fred and Rose West. A bit gruesome but for you Drummond lathe enthusiasts there is a "guest" appearance by a Drummond round bed lathe ( about half way through ). If you do tune in you won't believe where the guy is using it. Geoff |

| Thread: Murray's Hypocycloidal Engine - Antony Mount |

| 02/12/2017 20:34:39 |

Hi Mick Could I ask, what is the the throw on this engine and how has it been calculated? I assume from Jasons drawings the throw is the width of an inlet port plus the lap. So 3/32" + ? What I'm trying to say is how much is the lap and do you know why it is that amount? Just curious Mick I am making a similar engine with a similar size valve and trying to understand how the size of the lap is determined. best Geoff |

| Thread: Why Column gear shift |

| 28/11/2017 10:48:56 |

Column shift was great for changing drivers without stopping the car. My mate had a vauxhall with column shift. On the long runs to Uni in the late 60's he would partially stand up at the wheel, I would slide across the bench seat into the drivers side and he would step across into the passenger side. Easy peasy, just slow down to 30 while you make the change. Long time ago when we were all a bit crazy, well I was! geoff |

| Thread: What Did You Do Today (2017) |

| 24/11/2017 19:32:49 |

Does the slot create a reservoir for bubble mixture to allow larger bubbles to be blown? Expiring minds want to know! Expiring minds???? you sound good to me Mark. Hope you are with us for some time yet!!! Yes the slot may help but she 'aint getting another go! You've been busy, nice work, heavy duty stuff, phew!!! GEOFF |

| 24/11/2017 18:53:24 |

All surfaces are machine cut apart from the slit and the small end radius. My granddaughter popped into the workshop and saw me working on it. "Oooo that's nice Grandad I could blow bubbles with that. She was right!!!! geoff |

| Thread: 1947 Jepson engine |

| 23/11/2017 11:47:59 |

Hi Gents, A question if I may on the slide valve for this engine. The last photo in this thread shows the ports in the cylinder block. The outer dimension across the two inlet ports is 1/2". The ports are 3/32" wide so the inner dimension is 5/16". From what I have read (M.E. tyro articles by W J Hughes issue 2666 and 2670) the length of the cavity in the slide valve should be the same as the inner dimension (5/16" The drawings for the slide valve on this engine show a cavity length of 3/8". Is this fundamentally wrong, does the length have to be 5/16" or am I missing something? If you are a "Tyro" like me gents I can recommend the articles by Mr Hughes which also explain clearly the principles of lap, lead, angle of advance etc. cheers geoff |

| Thread: looking for a new bench drill |

| 22/11/2017 12:54:29 |

I'm looking for a new bench drill but a much smaller one suitable for indoor use. To be purely for small drills up to 3.5 mm. in a range of materials, balsa, plywood, M.S. brass, bronze etc. No heavy drilling the boxford union in the workshop does all that. There are numerous cheapy, cheapy, chinese ones around the £100 mark and all available via delivery from the far east. Not sure about these, look like glorified dremels to me? The proxxon TBH looks good but at a whopping £365 I would want some really good feedback and a up close look before i would buy at that price. The axminster XO at £312 also expensive but I do like the variable speed drive, digital readout and the scroll chuck. Arc euro are offering a sieg XO at £224 which looks very similar in spec and quality to the Axminster and has a ER11 collet chuck option . Any thoughts on or experience of the above guys? cheers geoff |

| Thread: Lever/Rack tailstock preferences |

| 20/11/2017 09:11:40 |

Steve, Yeah I also made a lever feed, two in fact, one for each lathe. A good lever feed should have really close fitting pivots so the whole assembly has a positive feel when in use Wouldn't make one now though, far to busy modelling to make accessories, I've moved on. P.M. me if you do fancy making one I can give you some ideas. Geoff |

| Thread: Will I ever need a reversing switch? |

| 20/11/2017 08:59:27 |

|

Simple answer with the dewhurst. Remove the handle, shorten it and then refit. No chance now of switching on accidentally and still plenty of leverage to operate the switch. I would always have a reversing facility as I have no milling machine and require more versatility from the lathe, also an M like yours. These set ups are a slitting saw on a morse taper milling arbour and on an arbour between centres. Reversing the spindle is essential here as when the work is fed forward into the saw via the cross slide you needs to up cut mill rather than down cut mill as would be the case with spindle running forwards. Keep the dewhurst Eug. Just wire it in alonside your NVR |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

. This would seem to me to be fundamental as with the side valve in a mid position both the inlet ports will be closed. If the slide valve cavity is any longer then both inlet ports will be open with the valve in the mid position, even if only by a small amount.

. This would seem to me to be fundamental as with the side valve in a mid position both the inlet ports will be closed. If the slide valve cavity is any longer then both inlet ports will be open with the valve in the mid position, even if only by a small amount.

Register

Register Log-in

Log-in