Member postings for _Paul_

Here is a list of all the postings _Paul_ has made in our forums. Click on a thread name to jump to the thread.

| Thread: Adept No.2 Shaper |

| 27/12/2013 23:18:49 |

Could it be because it will also double as a Bullworker® ? Handpower is fine but once you go beyond making keyways it can soon become tiresome.

Paul |

| Thread: Shaper cutting tools |

| 27/12/2013 19:10:59 |

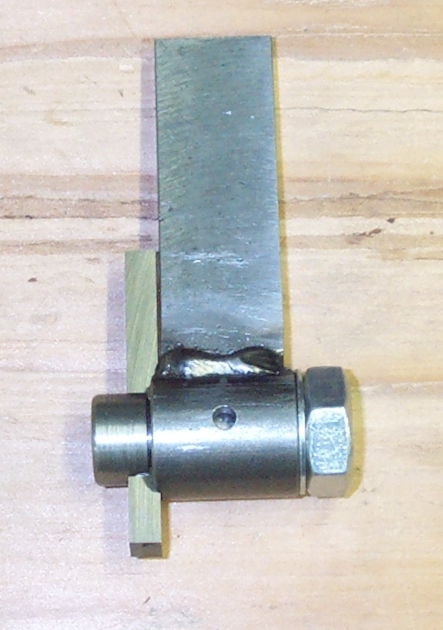

As previously stated lathe tools will do, you wont get any shop bought ones. Couple of books you might like which contain how to make your own: Ian Bradley "The Shaping Machine" Lathe and Shaping Machine Tools by "Duplex" Depends what you are doing but for general use I prefer this type :

Lets you use smaller chunks of tool steel, there are quite a few variations on this style some bought (Armstrong) and some shop made, the late Art Volz did this design some years ago. Regards Paul

|

| Thread: kasenit |

| 20/12/2013 22:16:48 |

Posted by julian atkins on 20/12/2013 21:42:00:

look after your kasenit as it isnt available anymore! cheers, julian Sadly true, however Blackgates do their own brand of case hardening powder witch works exactly the same as and has the same properties as Kasenit. I normally get mine from their stand at whatever particular event they and I are at. Paul |

| Thread: Use of language |

| 15/12/2013 19:39:31 |

Posted by John Stevenson on 15/12/2013 18:29:21:

Anybody seen my knitting needles ? lol |

| Thread: Shaper 3 phase or Single |

| 15/12/2013 08:59:22 |

Dual voltage (220/415v) motors should have a junction box on them which may if you're lucky have a wiring diagram in it, you will have to open the junction box cover and alter the "links" (brass strips with a hole either end) motors will vary by manufacturer but typically should look something like this Example of a STAR Mode (415V) Connection Example of a DELTA (220V) Mode Connection

Paul |

| 13/12/2013 13:02:03 |

From an earlier post here You could run it on an RPC which should be cheaper to make than the cost of an Inverter, that said the inverter will give variable speed and a lovely smooth finish. As a comparison my Alba 1a has a 1/2hp 3Phase motor and can produce a reallysmooth finish. My Elliott 10m has a 3/4hp single phase and will not produce the same quality finish no matter how much I tweak the setup/tooling/lubricant. Similar behaviour from both my single phase Boxford 8" and 7" Atlas. Regards

Paul |

| Thread: Chuck location on a Vertex Dividing head |

| 25/11/2013 23:31:28 |

I use the MT2 taper inside the Heads spindle to mount mandrel/s when gearcutting never a chuck. Paul |

| Thread: What did you do today? (2013) |

| 24/11/2013 20:56:53 |

Chromed spokes eh these cart wheels are going to be a bit like 1800s Ross Styles lol |

| Thread: eBAY Charges |

| 22/11/2013 01:01:02 |

Does anyone here sell on Ebid? if so whats your experiences (apologies to the OP for the OT post) |

| Thread: Tool chatter |

| 18/11/2013 16:02:16 |

If you have enough height to centre the tool try it in reverse IMHO you should see a difference. |

| 18/11/2013 13:25:03 |

What kind of parting off tool are you using?

|

| Thread: What did you do today? (2013) |

| 18/11/2013 00:37:51 |

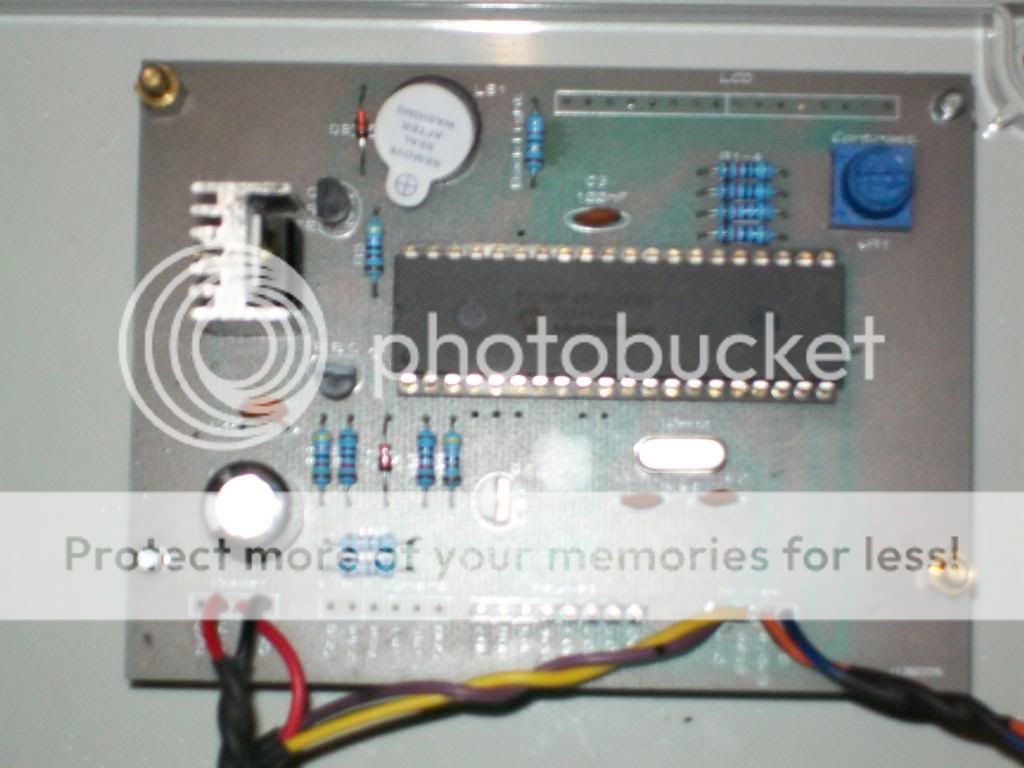

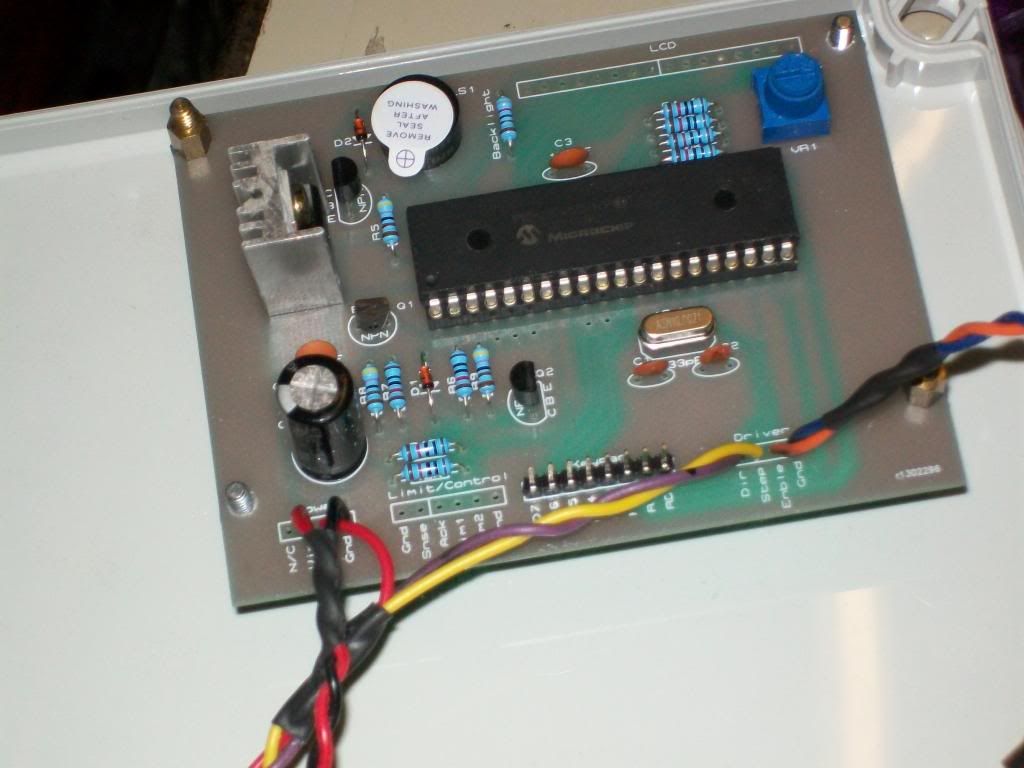

Made some progress with the construction of Steve Ward's (kwackers) rotary table controller got the circuit board soldered up and started on the box it will it in for now.

|

| Thread: Inverter |

| 16/11/2013 19:01:25 |

Posted by Stub Mandrel on 16/11/2013 18:41:55:

It issues a warning (which you can set to trigger an output) and if you carry on it stops the motor and gives an error code. It makes assumptions about the motor's 'thermal constant' which is given in seconds. Like many system variables this is set to a typical value and can be reprogrammed (presumably by those with lots of time on their hands or professionals setting up VFD/motor pairs for specific applications). Neil Yes know what you mean some of the manuals/menu's are like wading through treacle. So to fix this you could: Fit a temp sensor on the motor wired to say an Arduino to do two things: Once it hits "X" temp switch in an external fan you have secreted on the motor If temp still rises then trigger an E-Stop on the inverter but leaving the external fan running till the temp reaches an acceptable/normal level. Paul |

| 16/11/2013 18:50:16 |

Posted by Russell Eberhardt on 16/11/2013 16:50:58:

Personally, I just feel the case temperature by hand occasionally if slow running for extended periods. Russell. +1 And if you can smell burning insulation resin it's also time to give it a bit of a rest Thor, If I occasionally "jam" the Teco driven Bridgeport it does exactly the same but then it takes a complete shutdown of the inverter for it to recover, iv'e often wondered if this shouldn't be more of an E-Stop type event? Paul |

| 16/11/2013 16:36:43 |

Posted by Stub Mandrel on 16/11/2013 15:56:36:

My Jaguar Cub allows you to set the motor parameters off of it's rating plate, and uses these to monitor over current etc. and to calculate when the motor is at risk of overheating through slow running. Neil Sounds good what happens when it gets to the point where it thinks the motor is at risk does it shut it down? If you fit additional cooling to your slow running 3 phase motor to counteract the temp rise from lack of airflow can you override the setting? Regards Paul

|

| 16/11/2013 11:19:17 |

Posted by Russell Eberhardt on 16/11/2013 10:53:13:

Posted by SLOTDRILLER on 16/11/2013 08:31:23:

Other than motor voltage and frequency I have not noticed anything in the programming for maximum current but I would have to double check this , This seems to vary between makes. My ABB unit has to have the maximum rated motor current set. That enables you to safely use a motor of lower rating than the inverter. My Mitsubishi unit doesn't have that setting so if you overload the motor you may have problems however the same applies running the motor off a normal three phase supply. The smaller Teco-Westinghouse devices have no current settings either. |

| 15/11/2013 23:46:15 |

How strange... the recommendation to use such a setup came from Dave the chap that owns Drives Direct probably one of the biggest retailers of VFD's in the UK. |

| 15/11/2013 22:52:11 |

Posted by jonathan heppel on 15/11/2013 22:42:18:

Paul, what you're doing is fine as long as there isn't an overload any time. A DOL starter has thermal protection. Your small motors don't, and fuses aren't recommended for the drive's sake. You may well be fine for ever, but it is a potentially dangerous set up. Whats dangerous about it then? |

| 15/11/2013 22:28:23 |

I have one Teco 2HP Inverter which has for years been powering various different machines all with different size motors ranging from 1/3 hp to 2 hp with no problems at all. Swapping machines/motors is done by using a 3 phase socket and plug system. Paul

|

| Thread: shaper motor |

| 15/11/2013 18:20:22 |

Great find your machine looks complete. Star only motors very often have the star point in the outer layer of one end of the windings this requires the ties cut from the windings pick out the star point separate the wires extend/add some tails and you now have six wires coming out of the motor (Delta). If you feel adventurous there are a some good books in the Workshop Practice series written by Jim Cox & Graham Asterbury which describe how this is done. I have done many with great success. Here you can see the 3 original wires coming from the windings at the back of the pic and at the front the freshly exposed Star Point with the three wires now separated

You could probably find a motor repair shop to do it for you but if you like a challenge..... Paul

|

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in