Member postings for _Paul_

Here is a list of all the postings _Paul_ has made in our forums. Click on a thread name to jump to the thread.

| Thread: Rocol Ultraglide, Does it work for you? |

| 26/07/2012 18:53:13 |

Never used it but I see that Rocol also sell "ROCOL ULTRAGLIDE 68" Is that the same? If it is I wonder with a name like that if it's not some form of T68 spec slideway oil, same stuff I pay £20 a gallon for from The Baltic Oil Works in Newport. Paul |

| Thread: Shapers (obsolete or not) |

| 26/07/2012 15:28:42 |

Posted by Shaun Trewinnard on 25/07/2012 19:45:25:

I bought a shaper some months ago and have been a little diffident about using it for fear of messing it up. Ian Bradley's book has been mentioned which might be just what I'm looking for. Any ideas where I could obtain a copy? Shaun T Ian Bradley's book is OK but IMHO copies seem to be very overpriced, especially for the amount & type of content it also concentrates too heavily on the "Acorn" shaper (7" Atlas clone/copy). Here are some other tomes you may wish to consider:

Online you will find Machine Shop Operations & Setups (Chapter 7 I think) which is from "Cincinatti" tools and for a freebie it's very good. There are many others but I guess these are my favourites. Paul |

| 26/07/2012 12:20:35 |

Posted by colin hawes on 26/07/2012 11:27:42:

I wonder if I could make it do hacksawing ? Colin There are a few ideas online here's one on the NEMES site I've not made one (apart from the slitting saw) but from what I read the issue centres around chip clearance, the working area of the saw blade would have to completely exit the work for the chips to clear so to cut a 5" lump of metal you would need a machine with at least a 10" stroke to clear the chips. It's the same principle as my old Donkey saws both have 14" blades but only have a 6" stroke. Paul Edited By _Paul_ on 26/07/2012 12:22:17 |

| 25/07/2012 16:19:51 |

Thanks John I'll have to have a dig through my old copies, having started to make the Aloris/PhaseII type I am now sort of commited but I can change that.

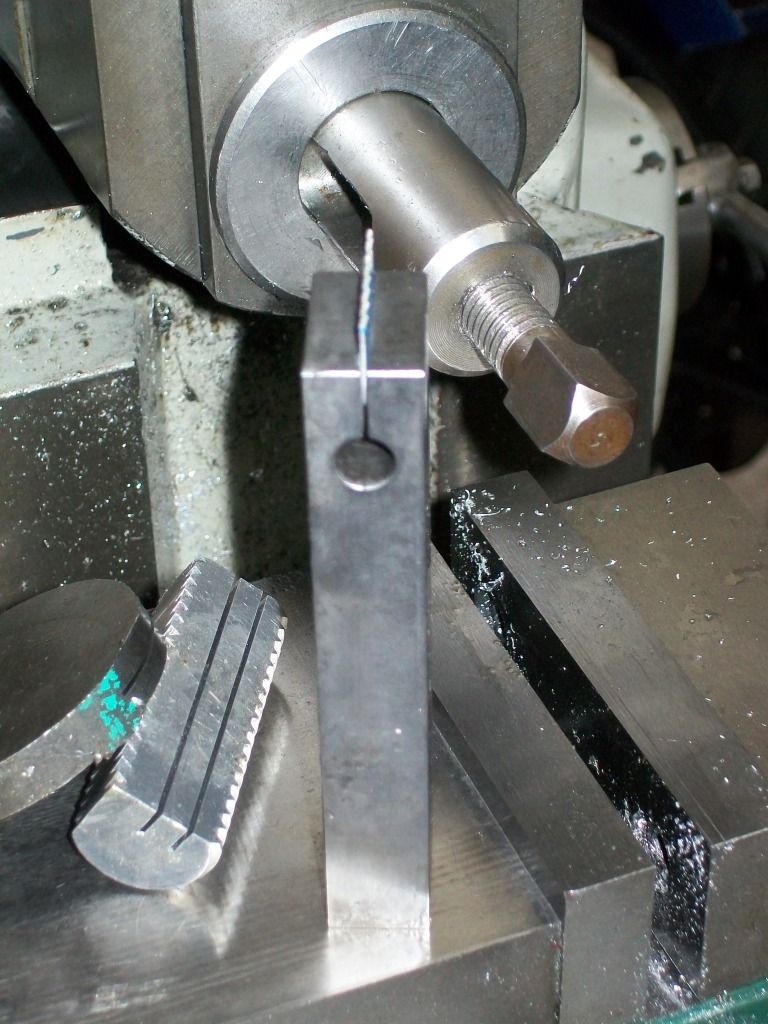

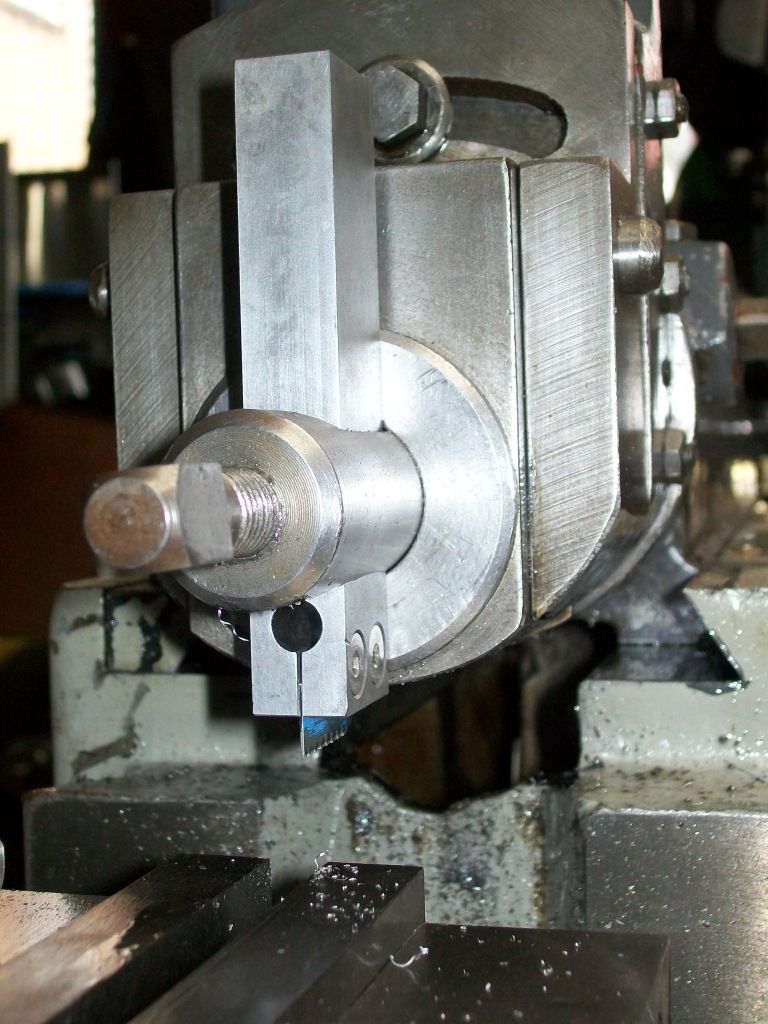

You make me quite envious any heat treat I have done is by yours truly and is never as good as I would like The Shaper can have some "diverse" uses I recently made this it's a slitting saw designed along the lines of Ian Bradley's (from his Shaping Machine book).

You may think this wouldnt have a great many uses but its great for slitting bushes and the like, uses scrap bits of old hacksaw blade as a cutter and unlike a thin lathe/shaper slitting blade it's 1" length means it dosent snap or shatter easily.

Regards

Paul |

| 25/07/2012 01:01:41 |

John

43 holders make my 15 or so look a bit sick My homemade ones are from chunks of unknown "scrapbinium" what material did you use any preference? Paul |

| 25/07/2012 00:24:11 |

I recently made some "Aloris" type toolholders for the AXA toolpost on my old Boxford and had to do some "infernal" dovetails.

In fact nearly all the facets of these were cut on an Elloitt 10M. Paul |

| 24/07/2012 22:27:31 |

I had almost forgotten about the floor (Apologies to the OP for the hijack BTW) OP It's not all rosy in Shaper Land tho the old saying is "You can make anything on a Shaper except Money" it's probably true as setups certainly need more consideration and can be harder to achieve than the average mill if you see what I mean. See if you can get someone to show you one working and perhaps even have a go yourself I am sure you will enjoy. Regards

Paul |

| 24/07/2012 16:26:03 |

£10 does sound a very fair price for sharpening something with that many flights. My cheapest (bought working) shaper is an Alba 1A cost me £70, include say £5 worth tool steel = £75 Your Dovetail cutter £35 and allow say around 2 sharpens? before it's done = £55 My math favours the Shaper

|

| 24/07/2012 15:15:17 |

So assuming our hypothetical dovetail cutter hasn't any chipped teeth and is suitable to sharpen what might that cost for say a 1" 60 degree item including carriage to mainland UK?

|

| 24/07/2012 13:55:21 |

So if one isn't armed with the equipment & or ability to sharpen say for arguments sake a very expensive dovetail cutter what do you do with it? |

| 24/07/2012 11:53:02 |

Posted by John Stevenson on 24/07/2012 08:26:31:

Shapers are brilliant at holding a section of floor down until you can find a more useful machine. John S. Do you still have one then John ?

To answer the OP yes they are worth having and not just to stop the floor flying away

I am a little biased tho I have five in total so I guess my floor is safe

Paul

|

| Thread: Removing surface rust on machined surfaces |

| 24/07/2012 00:45:41 |

Cyril I see from your link Frank uses Baking Soda (Sodium Bicarbonate?) I use Sodium Carbonate (washing soda) with the same effect, I wonder which works faster?

|

| Thread: marking / layout blue |

| 22/07/2012 16:54:39 |

In my experience the downside of using marker pen is I find the fact it will mark the paint on your machine. Cutting oil certainly does wash it off, WD40 does this faster than Sulphur based and once washed off it finds it way onto the machines paintwork and stays there. Regards

Paul

|

| Thread: Lathe problem |

| 19/07/2012 20:22:14 |

If it's flying straight off the pulley/s they must be very badly misaligned? |

| Thread: Is this model engineering |

| 19/07/2012 14:15:34 |

If I remember correctly did'nt Professor Eric Laithwaite build a model of his precession "engine" using Meccano? Thats a little more than simple engineering I would say.

Paul |

| Thread: Annoying Adverts |

| 17/07/2012 20:28:04 |

TBH I have never seen another forum with as much clat or as many advertisements surrounding the page as this one... And you never hear of this kind of problem on the Home Shop Machinist or Mad Modder forums..... If everything here is all hunky dory then why so many complaints about it? My 2 pennorth

Paul

|

| Thread: Foot pump type suds supply? |

| 11/07/2012 08:00:11 |

@ Michael Cox Mike, do you have a particular washer pump you could recommend? as I am quietly leaning to towards trying a washer pump setup out it would be nice to start with a "known value". Do you suffer from corrosion and if so how do you cope with it the reason I ask is that I have a built in suds pump on one of my donkey saws and it always seems to rust the machine no matter how diligently I mop it up. Regards Paul |

| Thread: You know you are an engineer when... |

| 09/07/2012 18:48:48 |

You check the finsh of every metal object you pick up |

| Thread: Myford ML7 - Convert from Imperial to Metric |

| 09/07/2012 12:37:05 |

Posted by Ady1 on 09/07/2012 09:35:47:

Fit a 10 quid DRO to your cross slide one evening and be amazed The biggest problem is drilling the stainless jaws, they are TOUGH, you will need to drill them with carbide Put a decent cutting edge on a cheap masonry bit using a diamond sharpening "stone" and it will drill the hardened stainless of the caliper, thats how I fitted the DRO on my ML7 tailstock. |

| Thread: Shaper drive |

| 02/07/2012 20:59:29 |

Adrian, It looks a very well made machine as to it's lineage I would also say possibly Butler or perhaps even Hendey but then I am no expert on American shapers. IMHO I would lean toward an inverter, you already know how flexible they are, have a look on the Home Workshop site a chap on there (Gavin Oseman) sells competitively priced units. Steve, My Teco inverter parameters can be set to stop my mill spindle in what appears to be a turn or less, unfortunately I cant have it set that vicious as the inverter is shared with both my ML7 and Boxford lathes both of which have screw on chucks. It will stop the shaper quite quickly too not as quick as the mill as it has a bit more inertia to deal with but still quick enough.

Regards

Paul

|

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in