Member postings for Douglas Johnston

Here is a list of all the postings Douglas Johnston has made in our forums. Click on a thread name to jump to the thread.

| Thread: Chinese DRO opinions |

| 15/01/2020 17:31:48 |

My concern about buying this kind of thing from China would be the quality of the packaging. The scales are quite fragile and it is a long way from China. I often buy stuff from China and the packaging is seldom good. If you get a broken scale it might be a hassle getting a replacement. Doug |

| Thread: To use chuck or collets |

| 10/01/2020 15:17:41 |

The real pain is chuck changing. If you have the collet chuck fitted, chances are you need the 3 or 4 jaw or vice versa. There is no decent answer to this problem apart from muttering some favourite oath and getting on with changing the chuck. The collet chuck is more accurate but also more limited, so I would always go with a 3 or 4 jaw chuck first before buying a collet chuck. When you have all three it just increases the chuck changing problem, you just can't win! Doug |

| Thread: Ebay being clogged up by certain sellers |

| 06/01/2020 13:48:56 |

Posted by Neil Wyatt on 06/01/2020 12:54:03:

The best solution, if you can afford it, is to buy from suppliers who support our hobby rather than saving a few percent by going to random suppliers on eBay... Neil Yes, I agree in general for a lot of things, but for certain things the " few percent saving " can be a few hundred percent if coming from China, and then it becomes much more difficult to justify. Doug

|

| Thread: Australian Bush Fires |

| 06/01/2020 10:09:39 |

This is one of the main items of news here in the UK. The situation seems dire and perhaps it will make more people take climate change more seriously. I can only imagine the terror experienced by people caught up in the fires. Doug |

| Thread: Cheap gear cutters from China |

| 29/12/2019 18:47:08 |

Posted by Pete Rimmer on 29/12/2019 18:23:17:

The simple rule for sharpening them is always sharpen the face so it remains in line with the centre. This means you have to rotate the cutter to grind more off, rather than moving it.

Thanks for that tip Pete, every day is a learning day. It makes sense when you think about it, the trouble is it is so easy to jump in without thinking. Doug

|

| 29/12/2019 16:11:44 |

Posted by Jens Eirik Skogstad on 29/12/2019 15:51:24:

Douglas Johnston.. I has the gear cutter same factory as your gear cutter where there is marked on gear cutter: 上 Homepage Shang Gong: **LINK**

Edited By Jens Eirik Skogstad on 29/12/2019 15:54:33

Thanks for that link Jens Eirik, it looks as if the cutters are made in a decent factory rather than some backstreet outfit.Have you tried cutting steel with your cutters, and if so how well have they stood up with regard to wear? Doug |

| 29/12/2019 16:01:02 |

Posted by JasonB on 29/12/2019 15:45:03:

I bought a couple of similarly priced MOD1 cutters and although they did the job they were starting to loose their edge after about 70T each in 1/4" wide steel so you get what you pay for.

That is interesting Jason, as long as I stick to aluminium they should be fine for letting me try out gearcutting. They do also look quite easy to sharpen, so even if they do blunt quickly they can be touched up to give extended service. Doug |

| 29/12/2019 15:10:34 |

I forgot to mention the ebay number which is 162447654385 Doug |

| 29/12/2019 14:54:20 |

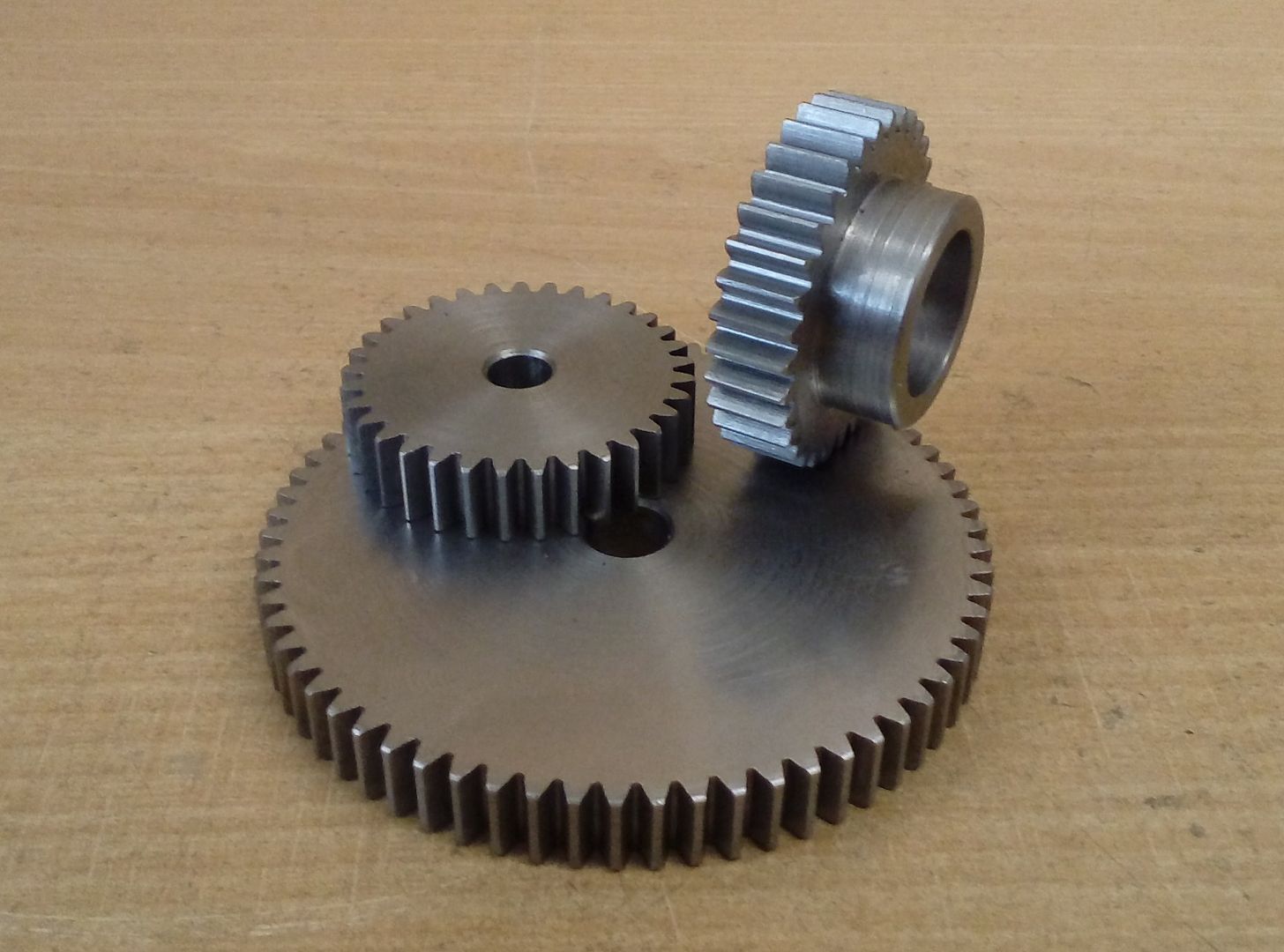

I have just received a set of 8 gear cutters from China via ebay and I must say they look rather nice. I have wanted to try gear cutting for a while but could not bring myself to pay up a lot of money for something that would not get a huge amount of use. I took a punt at the Chinese ones, not expecting anything great, but I must say they do seem well made. I have not used them yet so this is just a first impression, but at about £38 for a set of 8 cutters they do represent good value provided they cut well. The workshop is a bit cold at this time of year so I will have to wait a bit before trying them out, but at least I can sit in the warmth and look at them! Doug |

| Thread: Merry Christmas Everybody! |

| 24/12/2019 19:04:18 |

With 2020 vision I hope we all can see a bright future. Even Brexit (sorry! ) might look better. Doug |

| Thread: Scam alert |

| 19/12/2019 10:18:48 |

Just noticed this thread, I have also been getting these calls saying Amazon was about to take money from my account. This just started up after I bought something from Amazon and they said they were giving me a free trial of Amazon Prime. I did not want the free trial and searched the page at checkout to stop it, but it seemed I could not opt out. I nearly cancelled the order but reluctantly went ahead. I later checked my account with Amazon and found I had not been signed up to Prime and did not need to cancel. Then the phone calls started (about 6 so far ), so it would seem that Amazon has a security problem which I do hope they are taking seriously. Doug |

| Thread: Stevensons original collet blocks & Arc Euro 6" grinder |

| 18/12/2019 11:23:00 |

The dense foam sheet used for insulation makes a very good alternative to wood for holding collets. I made one up for R8 collets out of 50mm thick sheet and it is as good as new after 10 years. I used a large diameter end mill to cut out the holes for the collets and fitted it into a large plastic food box. When not in use the plastic lid of the box keeps the contents clean and dry. I have never been happy using wood next to steel parts due to the corrosion risk. Doug |

| Thread: Slip gauges |

| 14/12/2019 14:52:29 |

I bought an imperial set of used carbide ones off ebay a while back for about £100. Being carbide there was no rust but a few of them were slightly chipped. They appeared to have had quite a bit of use, but were from a very good UK maker with an original price of over a grand, and still in a condition to be very useful. For hobby work they do me fine and if I was doing it again I would love to inspect them before purchase, but that is seldom possible. Doug |

| Thread: Aldi bandsaw |

| 14/12/2019 09:30:30 |

The vice seems to get a lot of criticism with some hardly holding at all and others much better. I seem to have been lucky as mine holds pretty well but I wonder if it will stay that way long term. It must be poor design or poor manufacture that causes the variation. If the vice becomes sloppy I will replace it with something better. I don't think we can complain too much bearing in mind the relatively low price of the Aldi version. The blade also seems to be of high quality. Doug |

| Thread: cut knurling |

| 09/12/2019 18:03:47 |

Thanks for that Michael, the pictures show the mechanism much more clearly. If anybody has experience of using this type of knurling tool could they comment on ease or otherwise of use and whether a good knurl is more likely than with the clamp type. Doug |

| 09/12/2019 09:44:43 |

I have just been looking at issue No288 of MEW and was intrigued by the picture on page 10 of cut knurling. I have never been able to get a good knurl with the usual clamp knurl tool and was quite taken with the quality of the knurl in the picture. Unfortunately the picture does not give a complete view of the tool and I can only assume there must be a second straight knurl wheel below the one shown to produce a diamond pattern. Is cut knurling a better way to produce a decent knurl and if so are there any plans out there for making a DIY version. Mention was made in the article about an article in ME 4543/5 but I don't have access to those. Doug |

| Thread: Breaking bandsaw blades |

| 03/12/2019 20:21:33 |

Thanks for your explanation about the wire Brian, that all makes perfect sense so I must find a length of wire and have a go with my machine. I was watching a youtube video about silver soldering a broken blade recently and the chap did not scarf the joint but simply cut the ends carefully then fluxed and soldered them. The result seemed to be fine but I did wonder how strong silver solder is over such a small area. I may give it a go to see if it's just as good as a scarfed joint. It would be easier to prepare the ends and might help prevent thickening of the joint after soldering. Doug |

| 03/12/2019 14:21:05 |

Posted by Brian Wood on 02/12/2019 20:47:42:

The method is easy with a stretched wire round the blade wheels and through the guides, it will show those faults as in no other way. When I had put my guides right, blade breakage stopped as if a tap had been turned off. Regards Brian

Brian, that sounds interesting, why is a wire better than a blade? Can you give more detail about how you set this up and what to look for by way of sorting out problems. Doug

|

| 02/12/2019 17:59:30 |

Don't throw the blade away, you can silver solder it back together again. Plenty advice on youtube. I have also noticed the jumping as a blade is about to break and wonder if badly adjusted guides may cause this. Doug |

| Thread: Recommend a Small Parts Lathe for £2k. |

| 01/12/2019 15:12:32 |

The Myford ML10 or preferably Speed 10 is by no means perfect, but I have been using one for the past 30 years or so and rate it highly for what it is. It is compact, has a quality feel to all the controls and would be worth considering for the type of work required by the initial poster. I have nothing against the small Chinese lathes, and I have looked at a few in my time, but they don't have the same quality built into them. Doug |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in