Member postings for Robin

Here is a list of all the postings Robin has made in our forums. Click on a thread name to jump to the thread.

| Thread: Space Ship leaves Earth's Atmosphere |

| 26/11/2018 11:34:44 |

Maybe it needed the extra power because it had to lift a Saturn 5 |

| Thread: Lead Bearing Solder is Banned |

| 24/11/2018 09:27:01 |

Posted by Mark Rand on 24/11/2018 00:29:25:It's just a stage in the progression towards punt guns

No, I don't want one. I want two |

| Thread: Drill Chuck Falling Off |

| 22/11/2018 00:20:55 |

Would it shrink on? That is not a suggestion so much as a question |

| Thread: Lead Bearing Solder is Banned |

| 21/11/2018 00:48:30 |

Hi Robert I'm not quite sure why but I seem to be collecting blunderbusses, it's probably just a phase I'm going through

|

| 20/11/2018 14:32:05 |

Posted by SillyOldDuffer on 20/11/2018 13:44:58:

What is your mystery item? I'm not sure I want to tell, because you lot might tell me it isn't what I bought it as and burst my bubble. I really enjoy owning the rifling cutter for a Lewis gun |

| 19/11/2018 15:30:29 |

SODu if you want examples, try Googling "Nanny State".

|

| 19/11/2018 10:07:02 |

Posted by Robert Atkinson 2 on 18/11/2018 21:18:17:

I hope you have a EPP licence for the lead acetate Thanks for that useful warning. Did you know that according to Arthur Ransome, duffers are likely to meet a watery end? Take care around boats. Here's something else I should not have...

|

| Thread: Changewheel conundrum |

| 15/11/2018 00:23:16 |

I like that... a ,125" lead screw times 120 divide by 127 equals exactly 3mm Last 2mm pitch I cut I used 25:40... .125" x 25 / 40 = 1.984mm that's 16 um short. |

| Thread: Lead Bearing Solder is Banned |

| 15/11/2018 00:03:38 |

Posted by SillyOldDuffer on 14/11/2018 10:18:35:

With respect Robin, that's not evidence! Big jump from a photo of an interesting survival to 'I don't think lead in landfill is half the problem it is made out to be.' There's plenty of evidence that Lead is poisonous. I wouldn't suggest lead acetate, the so called Sugar of Lead ,as a sweetener. That's been tried in the past with terrible consequences. I have a pot of it for making slow match, it burns without the hard coal you get with saltpetre. Anyway, how is the lead in the solder going to poison me? Not by inhalation, I do a lot of soldering and it is always the tin that boils off leaving a pasty lead crust behind. I suppose not washing my hands before eating a sandwich might be my downfall. I remember some workman showing us a terrible cut across the palm side of his fingers he had got from lead flashing. He had a decorative hankie knotted over it and everyone was muttering about lead poisoning. This was the 1950's and I was already expert on skinned knees, I reckoned it just looked like it needed drying out. Anyway, I appreciate your concern, I will take more care around the dreaded Plum bum and strongly suggest nobody looks to me for Health and Safety advice. |

| 14/11/2018 01:47:28 |

Here's a piece of lead/pewter, an apostle cap, a dinky spout for pouring gunpowder into your matchlock musq't. It must have been lost c1640 then waited for a metal detectorist to visit the battlefield, recover it and sell it on eBay. The lead has hardly degraded, even the little loops for the strings are stil there. I don't think lead in landfill is half the problem it is made out to be. |

| Thread: What did you do Today 2018 |

| 08/11/2018 10:00:36 |

Posted by Joseph Noci 1 on 08/11/2018 06:34:25:

The second part of the post on the voltage/rpm tests on the stepper and damper.. I've missed a lot of this but it looks wonderful. To hob a 14 tooth gear with a 40:1 reduction worm requires virtual gearing 14:40 Assuming 400 half steps/rev on the motor it works out beautifully 400 x 14 / 40 requires 140 steps/rev. I'm guessing you are 3d printing quadrature encoders to go on the spindle. The easiest way to read a quadrature encoder is to combine new data with previous data, turning 2 bits in to 4 and then using a look up table to get step and direction. I know I am a nosey git, but am I right? |

| 05/11/2018 12:28:24 |

Posted by Mike Poole on 05/11/2018 12:16:42:

Unfortunately the transformation wears off all too quickly, the fall off in performance is like boiling a frog, But it is glorious, if it lasts for a week then I will count it as money well spent

|

| 05/11/2018 11:33:48 |

After having to find a torch to read the jaw numbers in my lathe chuck on Saturday, today I replaced all the flourescent tubes and starters in the workshop. Cost me 50 quid and now I'm thinking I might need to buy some sun glasses to make it habitable |

| Thread: Myford ML10 change Wheel question |

| 31/10/2018 23:12:57 |

Posted by Brian Wood on 31/10/2018 18:16:02:

Your quadrant could be recovered by careful brazing of the broken pieces, it would be stronger than trying to fix it with small screws. We are not going to agree on anything, but I still like the way you think Robin |

| 31/10/2018 11:44:23 |

I am not sure about that, but I am not here to argue I left it unattended on a slow feed once. The saddle pushed the headstock back until it snapped the bottom of the gear quadrant off and graunched the lead screw under the split nut. Seeing as how both results would stop the saddle I think it is most unfair that I had to suffer both. Anyway, since then I leave a slow feed gear set up and avoid thread cutting. Too much regret when I have to hold the pieces together whild locking the quadrant. Perhaps I exaggerate, if I really cared I would drill and screw the quadrant it back together |

| 28/10/2018 20:55:20 |

Posted by Brian Wood on 28/10/2018 15:54:08:

I don't know what gears you do have available, but the combination 25/40 x 63/60 x 3.175 produces a thread of 2.084 mm pitch. It also I think corrects direction so that you can cut your left hand thread. That's what I have on the table inside the gear cover. BUT my simple 25:40 does not involve buying a new 63 tooth change wheel and is out by .016 mm which beats their .084 mm Very odd. Is there some advantage to erring on the plus side? |

| Thread: For discussing the merits of alternative 3D CAD programs. |

| 28/10/2018 20:13:45 |

I got Alibre on a £99 special offer thing and I have renewed on special offers since then. I currently have v2017 on my PC. I think I prefer Fusion. However, unlike Fusion only your maintenance contract expires not the whole caboodle. I got Fusion on a 2 years for the price of 1 special offer and then rummaged around to turn off the auto-renew. If I draw something I need to keep I will have to make sure I have a real copy and none of that cloud nonsense. I use a cheap AutoCAD clone called ProgeCAD. It works okay, it has a few bad habits but nothing I cannot work around. I use Alibre and Fusion for 3D printing, I use ProgeCAD for machining 2.5D. I build the shape using circles, lines and arcs then extrude them vertically using the elev and thickness variables. I export as a .dxf and them process that. I have plans to try Fusion tool paths, looks like fun. OTOH, I use Protel Autotrax for PCB design so what I do is probably not worth your consideration Edited By JasonB on 28/10/2018 20:18:51 |

| Thread: Myford ML10 change Wheel question |

| 28/10/2018 15:11:40 |

Posted by Brian Wood on 20/08/2018 19:45:09:

It is the overall ratio of the change wheel gearing, including the fixed 25T gear, multiplied by the lead screw pitch in mm which at 8 TPI is 3.175 mm Useful post. So I want to cut about an inch of left handed, M30x2 thread for which I have a die nut. I divide the leadscrew 3.175mm pitch by my required 2mm pitch then multiply by 25 teeth on the head stock and find I need a 39.6875 tooth gear on the lead screw. Dont' have one of them but I do have a 40t. 3.175mm x 25 / 40 = 1.984375, so over my 12 threads I will be out by 0.1875mm, about 7 thou. Only tricky bit is I will need 3 idlers to get the bottom gear turning in the same direction as the top for a left hand thread. That wasn't nearly as hard/expensive as I expected. Well done Brian Edited By Robin on 28/10/2018 15:12:59 |

| Thread: Micro drilling |

| 18/10/2018 14:03:12 |

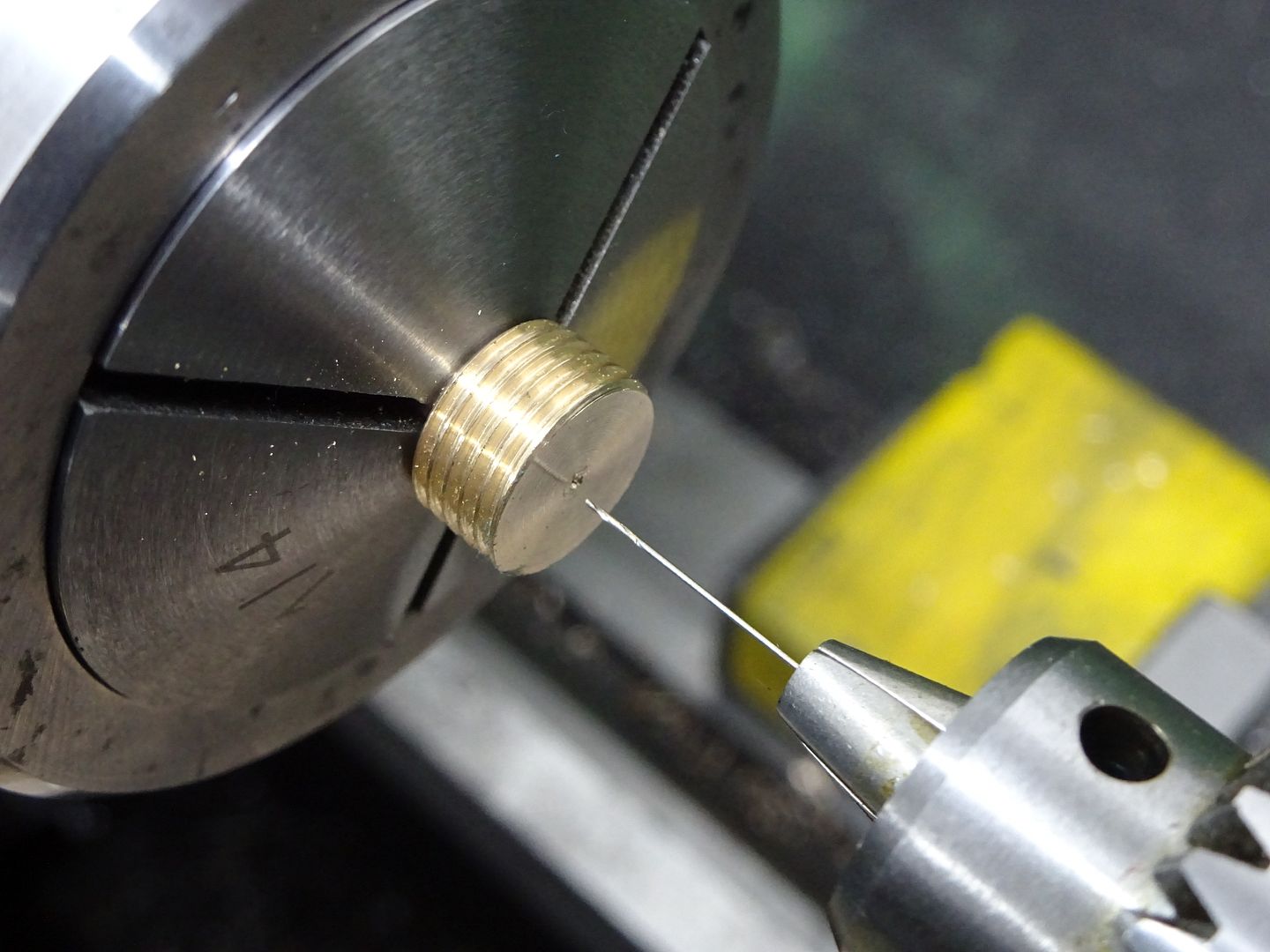

Posted by JasonB on 10/10/2018 15:09:10:

What wire gauge as 10swg is not exactly small? I drilled 0.3mm the other week, faced, small spot drill and then in with the 0.3mm bit.

That looks so far out it isn't true (as they say). Perhaps it is the camera angle or something |

| Thread: which compressor |

| 17/10/2018 11:51:24 |

I was given a compressor because my brother couldn't stand the NOISE. Neither could I. I now have 2 Bambi's, permanently on and no louder than the fridge, (probably because they use fridge compressors) |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in