Member postings for Michael Bird 1

Here is a list of all the postings Michael Bird 1 has made in our forums. Click on a thread name to jump to the thread.

| Thread: Need help on wiring a three phase motor |

| 05/12/2016 15:56:47 |

Here is the plate: |

| 05/12/2016 15:39:22 |

I have just bought via a local auction a brand new Brook Crompton 3 phase dual voltage 550w motor for a bargain price The idea is to join this up to a single to three phase inverter and connect this to my milling machine. I haven't bought the inverter yet. Below is a photo of the terminals as it is now and I think it's connected in star configration and to connect it to delta configuration I need to undo the black, brown and white leads connected to "N" terminal and do the following: A : Connect Brown to Red B: Connect White to Yellow C: Connect Black to Blue Leaving "N" vacant. Is this correct do far?

What I really need to know is the four core cable that I connect from the Inverter to the motor, which wires go to ABC. Does it matter which wires go to which phase. The earth goes to the body of the motor of course but where do the rest go. TIA Mick |

| Thread: Purchasing a Milling machine |

| 11/11/2016 17:37:30 |

If you are putting the mill on a bench make sure you have enough ceiling height. I have mine on a bench and luckily as I didn't check it just fits. The WM16 has 370mm gap between table and spindle, but then you need to take into account a collet chuck of some sort, your cutter, and then maybe a vice so with a 240mm high part you are really very close to your limits, in fact I don't think there will be room. |

| Thread: Can these motors be ran via a VFD |

| 08/11/2016 16:18:28 |

Thanks for all your advice. The price sounded good but as you all say the negatives out number the positives so I'll stay well clear. |

| 08/11/2016 14:44:34 |

I want to buy a three phase motor for my milling machine which is a Sharp Mk2 universal miller. I also need one for my Myford ML7. These will be ran from a 1 phase to 3 phase invertor or VFD. Can someone have a look at the following links and tell me if these motors are any good. They are dual voltage so hopefully are. TIA |

| Thread: What Did You Do Today (2016) |

| 07/11/2016 21:59:56 |

Over the last week I have made myself a power feed for the X axis of my milling machine. I can't seem to embed a you tube link so please click on the link [YouTube:xawToAuJj1Q&feature=youtu.be] Edited By Michael Bird 1 on 07/11/2016 22:03:27 |

| Thread: Myford ML7 for turning Aluminium |

| 04/11/2016 18:55:26 |

Well I have a Myford ML7 and it turns aluminium really well and gives a fantastic finish. |

| Thread: I need help choosing correct machine vice. |

| 15/09/2016 20:39:50 |

Thanks Mike I will look into those you mentioned. Just out of curiosity is the vice in the photo a shop bought one or a one off hand made one. It looks quite easy to build yourself.

|

| 15/09/2016 16:51:44 |

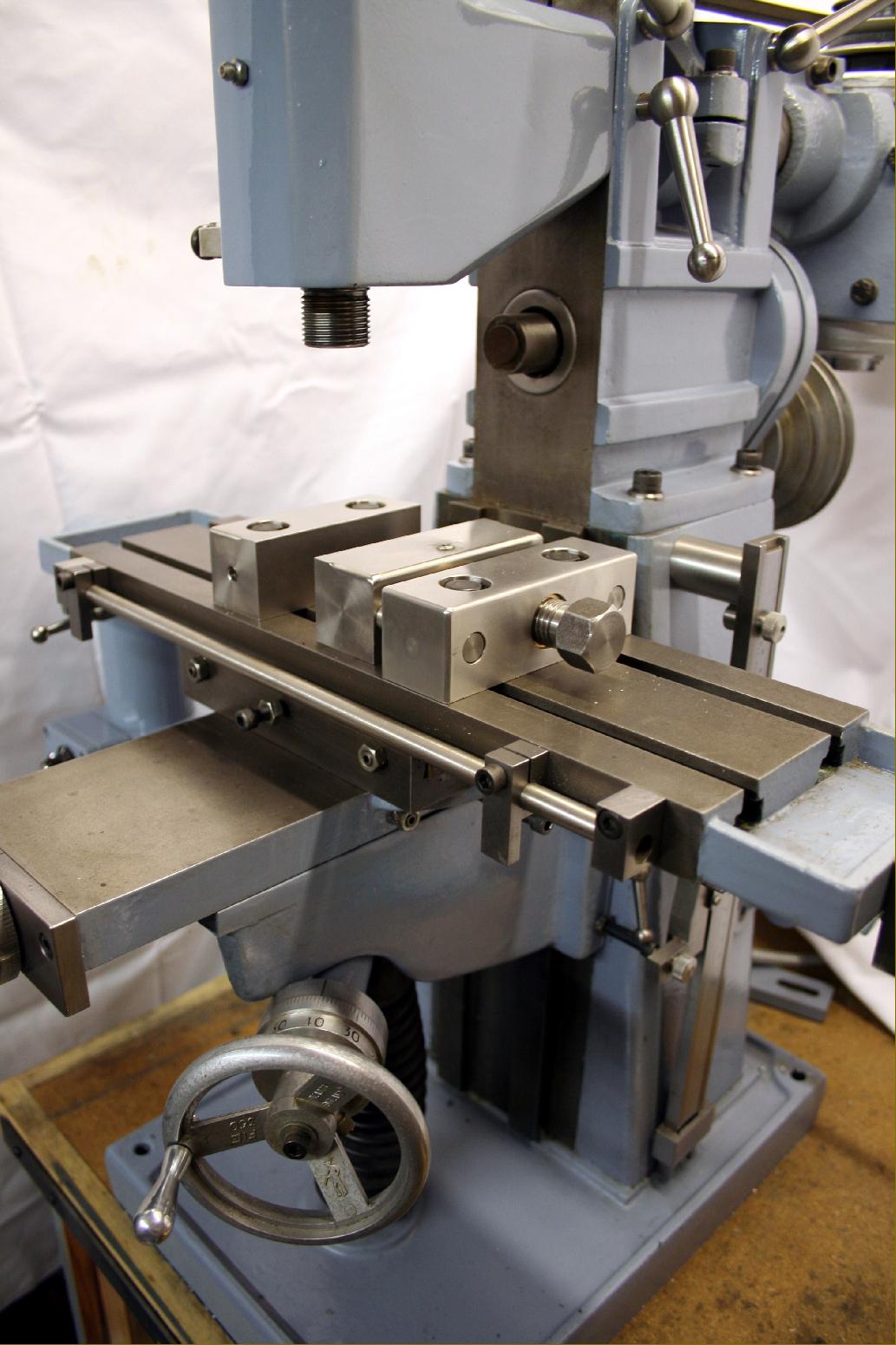

Rod does have the same mill as this one Jason. Headroom is a major factor, I have not bought any tools yet but was thinking of either MT2 collets held in place via a drawbar or buy MT2 arbors and drill a hole for the cutters held in by a screw. The Milling machine came with a Clarkson Autolock chuck as well but once fitted it leaves only about 100mm of space so need something slimmer. |

| 15/09/2016 14:49:51 |

There is no quill on this milling machines, you have to raise the table instead. Hence why I bought a large drill as well. Thanks Ian I'll have a look at the Arc Type 3. Edited By Michael Bird 1 on 15/09/2016 14:50:03 |

| Thread: My workshop build |

| 15/09/2016 14:23:27 |

It's a big project Muzzer, reminds me of the time I helped my father build his double extension on his house. I learnt so much doing that I helped the builder build my extension to. Good luck with and I look forward to seeing some photo's once it's done. And George I'll look into Celotex for the ceiling. |

| Thread: I need help choosing correct machine vice. |

| 15/09/2016 14:05:23 |

I need some advice on what machine vice to buy. It's going to be a Christmas present so I have a little while to consider which one. I have a Sharp Milling Machine which I have posted a few photo's off, one to show the table itself. The specs are as follows: Table size: 508mm x 241mm Table Travel: 305mm Cross Travel: 114mm Rise and Fall: 268mm Throat: 127mm Is there any advice on what vice to get as there are so many to choose from. Mick

|

| Thread: My workshop build |

| 15/09/2016 13:18:06 |

I have considered how long the felt will last, I have seen sheet material called coroline that looks like a tiled roof. I was considering putting that on the roof when the felt does eventually wear out. It's similar to this stuff: http://www.screwfix.com/p/coroline-corrugated-roofing-sheet-green-2000-x-950mm/5171j

Edited By Michael Bird 1 on 15/09/2016 13:22:21 |

| 15/09/2016 11:09:37 |

P.S. ... That was a very good price for 30mm MDF ... Just make sure you keep it dry. Edited By Michael Gilligan on 15/09/2016 11:02:36 It might have been a good price but boy were those sheets heavy, I can tell you it almost killed me putting them down. Thanks for the tip about a bucket of sand, can't get cheaper then that. And by the way I already have first aid kit, as I'm always cutting myself. I already have that web site book marked Michael. It makes a very interesting read and I would like to do something similar in the future. Edited By Michael Bird 1 on 15/09/2016 11:11:08 |

| 15/09/2016 10:36:07 |

Wow so much good advice, I now know I've joined the right forum. The gas fire is going that's for sure, I already have a 2Kw electric fire I use for camping, I was just unsure of the costs of running it. A humidifier is also on my list as is a fire extinguisher, there's so much to buy. I did think about insulating the roof when I was building it but for some reason I didn't. It's a good idea and will most likely be my next major project. I can see the benefits of it that is for sure. The reason I put a 30mm MDF floor down is that I got 6 1220x2440 sheets for next to nothing. The shed already had a 25mm floor sitting on 50mm square joists so I laid the 30mm floor on top of it making it 55mm thick, I thought it would take the weight of everything. It feels good and there is no movement or bounce anywhere. As for what I'm going to make in it I'm not 100% sure. I haven't touched a lathe or milling machine for 32 years so firstly just practice making swarf. My other hobby is astronomy and I have a nice telescope set up so will make a few adapters and then design and build my own Alt/Az mount and maybe if I'm any good a EQ mount. Finally I would love to build some steam engines one day. |

| 14/09/2016 21:38:35 |

Thanks guys. Yeah the red light is so I can set the scope outside and use the workshop as a warm room. The red light protects my night vision. Alan whats the problem with the gas heater then? |

| Thread: Help with identifying an old lathe |

| 14/09/2016 19:36:25 |

I would say it's a Drummond Round bed lathe. Take a look at the following link: |

| Thread: My workshop build |

| 14/09/2016 19:00:07 |

I have spent the last 6 months building my workshop. I started with a 16' x 12' shed and I insulated the walls, ran electrics with 12 double sockets, and then boarded the walls and painted them. The lighting is 4 double striplights 5 foot long. The floor is 2" bearers carrying a one inch timber floor which is insulated and then a 30mm MDF placed on top and a rubber matting on top of that. I have built two benches, one to house the machines and the other to work at. The whole build log can be viewed here: Here's a few photo's.

|

| Thread: Hello from Nottingham. |

| 14/09/2016 17:35:08 |

My other hobby is astronomy and I run a forum called "East Midlands Stargazers" so the plan is to build myself an Alt/Az mount and then who knows, if I'm any good maybe an EQ mount. Then finally start building steam engines when I'm fully kitted out. Yes the Sharp is pretty amazing and my first project is a power feed for it, I'm designing it now. I'll start a few new threads with some photo's.

|

| 14/09/2016 12:42:09 |

Hello everyone, I've been a member for quite some time but this is my first post. I've been building a workshop since March this year and it is nearly finished. I have a Myford ML7 from 1948 which is fully reconditioned and a Sharp Universal Milling machine which is almost like new. It's 1989 vintage and I have the sales invoice, it looks untouched so hopefully works well. I'm now collecting when money allows a selection of drills, taps, cutters etc. The list is endless but I am slowly getting there. A little about me, I live in Nottingham and I done a engineering apprenticeship as a Fitter/Turner about 32 years ago and since then I haven't touched a lathe so have more likely forgotten more then I remember. I was made medically retired from work a few years back due to a bad heart condition but feel a lot better now so want a little hobby. I will post some photo's up later. Speak soon. Mick. |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in