Member postings for Martin Newbold

Here is a list of all the postings Martin Newbold has made in our forums. Click on a thread name to jump to the thread.

| Thread: Starting to build fast speed gear for Drummaond Lathe Rebuild |

| 18/02/2017 13:34:28 |

Hi Ian , I could not find any just 303 Stainless so have gone for that . Did not say what it was made of so hopes it is 3/4 and not nearly 3/4. Am really hoping this is all going to work as not going to import a switch until i get somewhere with speed . Will need to figure it out though most likely need to move the motor control else where as its in way

Thanks M |

| 17/02/2017 20:23:37 |

I presume something like this would work http://www.ebay.com/itm/1-5-hp-2-hp-Electric-Motor-Reversing-Drum-Switch-Single-Phase-Position-Maintain-/151575110407 |

| 17/02/2017 19:14:24 |

|

Well have decided it might be time to take the electrics of the top of the motor I have and retro fit on on the bench . I have seen dewhurst and many other reversing levers on ebay but know in my box the switch is a very complicated beastie even though its single phase with a big cap its kitty motor I think would it be difficult to convert this to a dewhurst or similar switch what is involved can anyone give any suggestions please?.

Thanks M Edited By Martin Newbold on 17/02/2017 19:21:18 |

| 17/02/2017 16:59:19 |

Had not cleaned up welding so the seatings were not seated properly forcing an odd angle . Much better now they have been cleaned up . My maths has been thus n1 = 1600rpm, d1 (Drive)=25mm, d2 (Pulley drive )=130mm d3= 100mm d4 (on lathe ) =130mm n4=(n1 *d1*d3)/(d2 * d4) n4 = (1600 x 25 x 130)/(100 x130) n4 = 400rpm I just need a longer 3/4 silver steel bar around 12" long as he width is wider than my original pulley bar Edited By Martin Newbold on 17/02/2017 16:59:37 |

| 17/02/2017 14:10:50 |

Lol the profile was not good at all but ok for simple jobs have fabricated out of proper right angle and have it working in rough mock up pending new rod. The B&Q steel not iron was thicker at ends and narrow in centre the items I had was not right angles inside or out. Perhaps they have changed this and thier new stock is different. I did not go back but brought else where.

First mock up |

| 15/02/2017 17:10:04 |

I made the securing pieces to bolt under top and roughly cramped together to see if it all slides .

|

| 15/02/2017 16:11:07 |

Well I had to buy new angle as the B&Q angle iron lol now mild steel was not regular or a right angle inside and out. This mean all the work i had done was rubbish. I have purchased proper angle from a wholesale stock dealer and have got back to were i was . I have decided to use 3/4 gate eyes for the winding mechanism and have some on order . I still have to drill top plate for old mounting bearing holes and have a dry run with it cramped up before both are welded. |

| 07/02/2017 17:42:30 |

Well i drilled bars and re-ground one which was sticking |

| 06/02/2017 19:23:22 |

Got a bit further |

| Thread: +Sanding a block of square milled lengths in one go |

| 01/02/2017 21:41:10 |

Thanks M |

| 01/02/2017 21:28:00 |

Is there a way to sand of multiple lengths by strapping the four square pieces together to get a flat sand across them all on a linishing machine? |

| Thread: Oil coolant pumps - which type of pump |

| 01/02/2017 21:25:13 |

Hi RJW yep still to big though any idea what pump motor the parts washer uses please? David by centrifugal i presume you mean like a slurry pump that will cope with particles I.e a rotating disc witch is like a slinger. John are carbonator pumps this centrifugal design is there a particle size limit Thanks for all your help M |

| 29/01/2017 11:59:32 |

Whats sort of pressure does the cooling pump ideally need to deliver?

|

| 29/01/2017 11:46:37 |

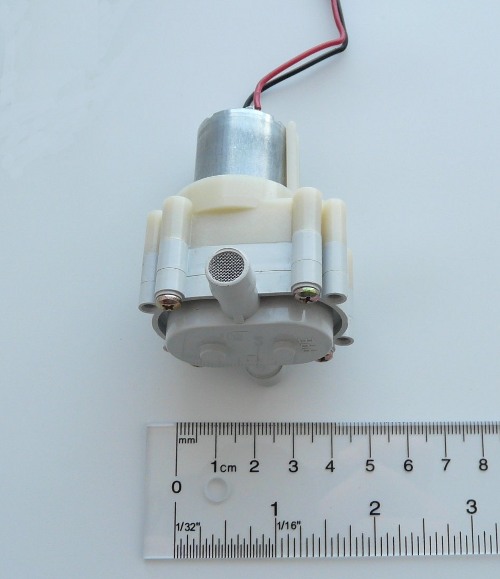

Hi everyone and thank you for the posts am looking for a small pump for a self build on a small lathe. My post was in relation to the types of pumps as there is a lots of types usually gears are used for oil pumps and not an impellar or propellor. I am wondering if there are any small pump motors that use gears to pump. This is a water pump but i wonder if they make metal pumps at this site . Does anyone know the viscosity of the cutting liquid please?

I was thinking of something like this Edited By Martin Newbold on 29/01/2017 11:57:15 |

| Thread: clarke cl430 lathe motor upgrade |

| 21/01/2017 12:40:00 |

Yes I agree Michael size is always an issue lol. But the advice is not good from suppliers or on web. Its very easy to buy something low powered and be led to believe it will all be good. By gears i mean pulleys to change speed which the clarke should have. Its easy to buy something which is not suitable . My purchase is testament to this I took lots of advice. The work shop I use of a friends has a 7.5 KW inverter which powers et all . It works well but was a great deal of money . If you are spending £500 you are not going to get this to work in the same way. |

| Thread: Replacement tailstock, sculpture or fabrication |

| 21/01/2017 12:29:20 |

Conversion of another tailstock is possible. The hardest thing is to find something that will fit your bed as the width are all different. The second challenge is the vertical height to center of lathe. I Converted my lathe recently it will give you a clue whats involved here **LINK** |

| Thread: clarke cl430 lathe motor upgrade |

| 21/01/2017 12:20:18 |

Lol don't change it . I brought Tec Motor and ABB Inverter and have had a silly amount of problems and lost money motor was sent back and never returned and gone back to single phase. If you are serious about it buy an Inverter which will power the lathe and use the gears to change speeds. and an inverter set up at around 1.5hp The low power VFD didn't work for me. I have a 1.5hp single phase motor now. Also pay attention to motor speeds of RPM . If you buy new motor it may be different to the motor you have, producing different speeds at the head. Your bearings may not cope with the speed change. Regards Martin |

| Thread: Look what followed me home: ML7 Myford |

| 21/01/2017 12:10:05 |

Great project just saw a you tube posts about setting up these and did not realise how the bed was bolted down was so critical. Itr seems that wrongly bolted down can cause conning across 3" of material. Have a look as it was really good video

Regards

Martin |

| Thread: Toolpost assembly |

| 21/01/2017 12:06:58 |

Um this is for a Boxford lathe and does not say Myford . Yes the collars should fit top and bottom the big one with step on top and the other in bottom. If the hole in the collars is wrong you may need to make new collars or make hole larger. You also so be aware what size tool post this is and how it fits on your lathe as the tool height needs to work with its adjustment to place it just below centre. Some bigger tool posts cannot do this with certain size tools. I have not got this far with my lathe but have been looking into it .

Regards

Martin |

| Thread: Oil coolant pumps - which type of pump |

| 21/01/2017 11:57:32 |

Hi everyone which type of pump is best suited to pump oil coolant on to machined item . Are there specifics about the type of pump that is most effective to pump this and material around. Can a motor drive a pump pulley as well as the lathe head? |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in