Member postings for SillyOldDuffer

Here is a list of all the postings SillyOldDuffer has made in our forums. Click on a thread name to jump to the thread.

| Thread: Mill recommendations |

| 20/05/2023 10:01:02 |

How much space do you have? And what do you want to do with it? General rule with machine tools is bigger is better unless specialising in small work. It's because big machines can usually do small work, albeit uncomfortably, but small ones can't do big. Anyway, assuming you're after a mill that will sit on a bench, there are various options. One of the many attractions of clockmaking is that the equipment doesn't take much space, and is clean and quiet enough to be done indoors: box-room, or under the stairs etc, Same applies to small-stuff hobbies like jewellery, model-railways, and makers adding modest metalwork to 3D printed items. The Sherline Mill is popular for this scale of work:

Or, bit bigger, a Far Eastern micro-mill, this example is sold by ArcEuro, an SX1LP, weight 50kg:

The micro-mill is first in a series of similar machines, each bigger and more capable. From Warco, the WM12 (weight 54kg), WM14(60kg), WM16(113kg), and WM18 (220kg) Of these, I think the biggest I would put on a bench is the WM14. A WM18 is much too big. Although the WM12 and SX1LP are similar, there are reasons for preferring one over the other. For instance, the SX does high RPM with a less powerful motor. This may be exactly what's wanted on a small milling machine. Small cutters work best at high-rpm, so with a 2mm diameter drill in the chuck, an SX should do better than a WM12. However, if the mill routinely tackles larger work (still small), I'd expect the WM12 to win, because it's more powerful motor can also manage the lower rpm needed. With a 6mm drill in the chuck, the WM12 has the advantage. Both machines will do the job, but they're not identical. Proxxon sell a micromill too:

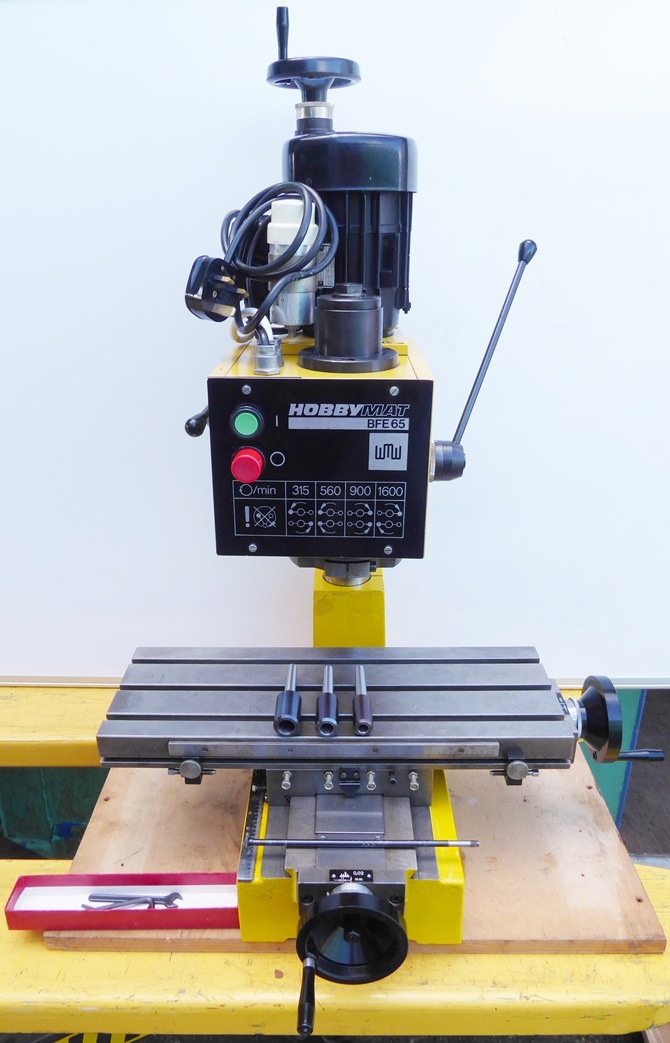

There are second-hand possibilities too, but with these condition is everything. This example is a Hobbymat:

Ought to say affordable small milling machines get mixed reviews. I suspect the problem is they have to be operated carefully within their limitations. They're not powerful or rigid, so anything remotely heavy handed will cause trouble ranging from low accuracy, to cooked electronics and burnt out motors via stripped gears! Patient delicate cutting rather than showers of red-hot swarf! Can you say more about what the mill is for? Clocks and motor-bikes are very different. Dave |

| Thread: MOI cad. It looks good, is it? |

| 19/05/2023 20:10:37 |

Posted by Peter Cook 6 on 19/05/2023 16:55:59:

Posted by SillyOldDuffer on 19/05/2023 16:41:34:

Looks like I have to retreat in confusion: I couldn't find anything on MOI's website suggesting it can do Assemblies, and yet here's Peter's clock. Must have missed it. Does the clock model animate? Oh dear, sackcloth and ashes, I shall have to buy Martin a pint... As I don't use the other CAD systems, for the reasons explained above, I am not 100% sure what you mean by "doing assemblies". That model is put together part by part - in almost exactly the way I would do it in the workshop. Each part is created individually (in my case mostly by hiding the rest of the model while I do so), then connecting or associated parts are unhidden using the browser and the bits put together, then the rest of the model is unhidden. That model was actually created by designing the three trains as separate MOI models, then combining them into a single one. It doesn't do animations, although I often use stepwise rotation of parts to ensure things don't interfere with each other. My retreat may have been premature, because that's not what I mean by an Assembly. I'd call it a group, that is a selection of bodies, each drawn individually, positioned adjacent to each other. In FreeCad the parts are identified in a tree from which they can be hidden or reworked. They are only related by their position in space. Here's an example of what SE means by an Assembly, Fusion is similar. It's a rough start at a Lazy Tong Riveter:

It's an assembly of 4 parts: a Brass "handle", an Aluminium pin, which runs in the slot, and an arm, 6-off. The arms are connected by 7 rotating joints, plus 1 rotating joint at a hole in the handle, and a non-rotating joint to the Aluminium pin, which has a tangent joint with the slot. As shown in the next mage, I've extended the arms by sliding the pin up the slot. Moving the pin operates moves all the other joints. This is the same model, except the joints have operated, Pulling the pin down moves all the joints and retracts the tong: Note the pin hasn't travelked the full length of the slot because an arm has collided with a corner on the handle. Joints are modelled too, allowing the Assembly to move realistically, and can detect when distant parts hit each other, as a result of the movement of 'n' joints away. All the parts can be used by other assemblies, and this assembly (with joints), could be assembled within another assembly, also with joints. If I change the original arm part, all the arms used in the assembly change. If the change breaks a joint, the assembly won't animate until the joint or other relationship is fixed. The model supports step-wise refinement, divide and conquer, and part re-use. As parts and sub-assemblies are independent, projects can be developed by teams, not just singleton developers. Next step in this riveter is to connect the far arms to a hinged cam that pulls a shaft and clutch that grips the pop rivet, all inside some sort of head. Then I'd add fasteners to join the tong arms together, and either drill and thread the cam to the pull shaft (two parts), or tap the shaft for a bolt (three parts). Both methods can be tried, because many cam and shaft variations can be modelled independently, and - provided they fit - can be swapped around. This is important in production : might be cheaper to bolt, because that removes one threading operation, or could be more convenient to thread the shaft. Or maybe the whole thing should be cast, drop-forged, or force fitted. Having looked again at the MOI website, I don't believe it does this type of Assembly. But I accept what MOI does is effective too. Dave

Edited By SillyOldDuffer on 19/05/2023 20:12:51 |

| 19/05/2023 16:41:34 |

Posted by Peter Cook 6 on 19/05/2023 16:34:48:

As Jason says there is no problem modelling parts and assembling them in MOI, but which tool you choose depends both on what you want to do, AND which ones you find easiest. I use MOI simply because I "get on" with its underlying design paradigm. Never having ben trained in engineering design or technical drawing I struggle to get my head around the paradigm that underlies the majority of the 3D CAD programs. This is an MOI model of a clock I plan to make. All the parts can be separated from the whole, and drawings or diagrams created to take across t the workshop. Drawing each part in MOI makes me think about the design choices, while putting them together in MOI makes sure that they fit together. One approach is not better than the other - they are just different, and at the limits are capable of different things. I will never reach the limits, so I stay in the middle with the tools that I find easiest to use. Looks like I have to retreat in confusion: I couldn't find anything on MOI's website suggesting it can do Assemblies, and yet here's Peter's clock. Must have missed it. Does the clock model animate? Oh dear, sackcloth and ashes, I shall have to buy Martin a pint... Dave |

| 19/05/2023 15:32:55 |

Posted by blowlamp on 19/05/2023 13:56:43:

Dave. When you said this: "MOI is good at curves, making it an excellent choice for 3d-print modelling. Also photo-realistic images, and designing decorative objects. It also appears to be easy to learn, and can do flat stuff as well. All considerable advantages if that's what's needed, but not for me. My needs are more 'mechanical engineering' , and although Solid Edge has surface tools that can do similar to MOI, I've never used them."

I must point out that MoI doesn't do photo-realistic images at all and it's not advertised anywhere that I know of for designing decorative objects, although you could do that if you wanted to. MoI is perfectly capable of creating an accurate model of anything from a vase to a jet engine, but not in a parametric way. This is why it can export in SAT, IGES and STEP formats, etc. The v5 beta that I'm running also uses the ACIS modeling kernel as well as Solids++. I'm fairly sure that the need to use surfaces will creep up on you as your designs change. Martin. Have you read the MOI blurb, or looked at the Gallery Martin? MOI say, my bold: 'Focused on being easy to use, it's a great tool for designers and artists who want to construct accurate models.' Designers and artists rather than engineers. Examples:

The last MOI example represents a record turntable. It's a broadly correct and scaled external view that could be 3D printed as a model, used to illustrate a forum post, or published in a glossy magazine advert. Great, so far as it goes, but tell me if I'm wrong: the turntable isn't an engineering model. It's an outer view of a turntable with nothing inside. Alibre, SE, and Fusion are different. They get outer appearance almost as a side-effect of modelling all the internal parts. This type of CAD models engineering assemblies, where each part, maybe thousands of them, are designed sufficient to make or source a real one. There would be a motor, drive train, arm-linkages, and all the other fixtures and fittings necessary to make a real turntable, positioned inside the outer casing. The model will often include trivia like washers, bearings, o-rings, fuse-holders, and cable clips etc. so the overall weight is always known, and a full BOM available. This type of CAD modelling is much more focussed on getting the engineering detail right than look, which is added later. The model of the arm assembly would be accurate enough to confirm that the counter-weight correctly balanced the cartridge, and also to swing across the record with the necessary geometry. After that the shiny good looks depicted by MOI are paint, putty and polish. MOI focusses on selling, whilst parametric CAD focusses on manufacture. Both are important. The MOI turntable model has many features designed to make it look top-quality hi-tech, but which are unlikely to be functional. MOI is top-notch for that, hi-fi fanboys would buy that turntable I'm sure. My sort of CAD model focuses on the practical, where the MOI's sexy rear 'heat-sink' is implemented as some chrome-plated plastic fins stuck on the back, whilst the engineering design uses intelligently sized standard items clipped on the transistors. MOI doesn't need to model the heat capacity of heatsinks, modelling for production does. There's a lot of overlap between the two approaches, but MOI punches hard at the artistic end, whilst Alibre and friends concentrate on engineering. In the middle both tools produce similar results, but I don't think MOI can model a jet engine as an assembly. How about a working lazy tong?

Dave

|

| Thread: Steam paddle steamer |

| 19/05/2023 14:11:44 |

Posted by noel shelley on 19/05/2023 10:32:06:

... And all for the want of a boiler ? Noel. I often think the boiler is the most difficult part of a steam engine. In comparison the engine itself is relatively straightforward. A large dangerous pressure vessel, full of tubes, prone to corrode and fill with mud, lots of joints to leak, access for cleaning and inspection needed, plus many gauges and external pipework, and a white-hot firebox. Marine boilers are more difficult than locomotive boilers too. They usually work at higher pressure and with much more attention to fuel economy. Likely the furnace is blown, directly or by pressuring the whole engine room. Having to replacing a marine boiler probably means its condenser is done as well, another expensive item. And then fitting new boilers often requires cutting large holes in the ship so they can be dropped in with a crane. Many other potential complications, such as an older vessel full of asbestos insulation, or the structure under the boiler is corroded. Generally a new maritime boiler means a full-refit, or close to it. £M Dave |

| Thread: Android CAD application |

| 19/05/2023 13:35:44 |

Never tried it. Though they have decent poke these days, I'm not sure Android hardware is man enough to run a full-blown 3D-CAD package - expect sluggish. Some of the Android products are readers rather than editors, which is practical. To me though the biggest objection is the environment and tiny screen. I struggle to think CAD unless there's peace and quiet, couldn't do it on a crowded train. But the really big problem is screen size. CAD is much easier with a giant screen, ideally two big screens. Or even three. Also with table space for a hefty mouse, and - for serious CAD - a 3D-mouse as well. Plus a full-sized keypad, a notebook, references, and maybe bits of the real thing to measure. Although CAD works OK on a laptop, it's downright inferior to running the same software on a fast workstation with two 24" screens. I think an Android would drive me mad, even a 10" tablet. Please try it and report back. My objection to small screens is partly because my eyesight isn't as good as it used to be.

Dave |

| Thread: Melt cast iron and brass with a microwave oven. |

| 19/05/2023 13:00:08 |

Posted by noel shelley on 19/05/2023 11:20:13:

Interesting ! but with only between 1 and 2 Kw even small amounts of metal will take a while to reach a pouring temp, never the less a novel idea ! There are also plenty of vids of induction melting but again with domestic power limitations it will be slow and stewed metal is like stewed tea, not so good ! For VERY small castings may be. To do an 8Kg melt - NO ! Noel. Yes, the chap's largest Aluminium casting is 20g, and I think Brass was an 80g casting failure. Low melting point metals are faster than than high, so perhaps 10 to 20 minutes for the Aluminium. Double or more for cast-iron. He also preheats the metal and crucible with a blow torch before microwaving them. Stewing is definitely a problem with Brass, because he asks for advice. Zinc loss always happens when melting Brass, and I think heating slowly to melting point would make it worse. Zinc fumes are toxic too. Overall I was impressed and there was some good problem solving done to get it working. As an electronics buff, my main beef is cruelty to magnetrons! Domestic microwaves rarely run flat out for that long! Main advantage I thought was melting metal indoors by plugging a cheap domestic item into the mains. Dave

|

| Thread: MOI cad. It looks good, is it? |

| 19/05/2023 12:24:33 |

Posted by blowlamp on 19/05/2023 10:46:01:

Posted by JasonB on 19/05/2023 07:36:49:

Posted by lee webster on 18/05/2023 21:30:17:

...

...... ... just a different way of getting the job done as I think MoI is classed as a Direct Modeler whereas Alibre & Fusion 360 are Parametric. ... Martin. That's my understanding. It means that MOI is better at some things than parametric modellers, and vice versa. In the middle, both do the same job equally well. The differences and overlaps make it difficult for a beginner to choose which is best for him, unless he understands what his needs are. MOI is good at curves, making it an excellent choice for 3d-print modelling. Also photo-realistic images, and designing decorative objects. It also appears to be easy to learn, and can do flat stuff as well. All considerable advantages if that's what's needed, but not for me. My needs are more 'mechanical engineering' , and although Solid Edge has surface tools that can do similar to MOI, I've never used them. What I want is:

Parametric is well-suited to designing complex assemblies. But of course the extra complication is a burden if features like Assembly aren't needed in your workshop. I use Solid Edge at the moment because it does most the above and isn't in the cloud. I found harder to learn than Fusion, which I like very much, but Fusion is a cloud product, and restrictions added by Autodesk to the free version annoyed me enough to look elsewhere. Like many hobbyists, I'm awkwardly placed because don't make enough use of 3D-CAD to justify spending big money on it, even though the full versions are highly desirable. It's a compromise. Alibre is definitely a runner: if Community Solid Edge was withdrawn, and a full license too pricey, Alibre Atom does most of what I need with a short learning curve because it's similar to what I already know. Maybe Solid Edge isn't a natural fit to my mindset, but I find it powerful rather than friendly. Synchronous mode comes with a multi-purpose steering wheel tool that does amazingly useful things, but is weird unless the operator understands a bunch of 'Design Intent' options as well. Once learnt stuff that takes a long time to do step by step in other CAD, is done very quickly by the wheel. Best for power users though, not beginners. I often use FreeCAD for single parts, especially when 3D printing. It's free as in beer and speech. Main problem is its a little experimental guv, so somewhat prone to crash, and early attempts at the tooling aren't always user friendly. So far the Assembly features are primitive, but it's strong in other aspects. Main fault from my point of view is the sheer range of workbenches provided, most of which I don't need. I'd rather the project concentrated on Mechanical Engineering, but it seems the Architects, Ship designers, Surface Modellers and other CAD specialisms don't agree. MOI is very tempting for that type of modelling. I like the look of Alibre as well - for other reasons. Dave Edited By SillyOldDuffer on 19/05/2023 12:25:02 |

| Thread: TWAIN |

| 19/05/2023 10:20:15 |

Posted by Michael Gilligan on 19/05/2023 04:21:28:

Posted by Clive Foster on 18/05/2023 23:04:08:

...

. ... Perhaps … just perhaps … all will become clear when I install Motic’s TWAIN driver ! But my presumption was that it’s comparable with [for example] the Arduino API, in that it provides functionality when you know how to use it. ” So can someone please point me to a decent introductory tutorial ? ” ...You shouldn't need a tutorial for TWAIN unless writing a driver yourself - it's a protocol and API allowing software to control image hardware, usually a scanner. For end users, TWAIN is just another driver. After installation, any application on the computer that supports TWAIN can select it from a list as an alternative to other drivers. (The application controls exactly how drivers are selected.) In the simple case, install the driver, start your scanner, and see if the scanner's config options allow the TWAIN driver to be selected. If so, it should "just work". I think Motic have pointed Michael to the high-end possibilities of TWAIN, not the end-user stuff. Their microscope has a TWAIN driver, so Michael could program it himself. Never looked at the detail, but I doubt TWAIN programming is beginner friendly. The TWAIN specification is here and Googling github TWAIN reveals TWAIN applications, development tools, etc. Not impossible to get into, but hard work I fear. There are the usual basic development gotchas to fix before starting work: Michael's machine is Apple, I prefer Linux and C++, and the nice example I found is C# on Microsoft W10. What are you trying to do with the Microscope Michael? Maybe someone else's project could be adapted. Dave |

| Thread: First workshop |

| 18/05/2023 19:15:15 |

Posted by Matt T on 18/05/2023 18:12:29:

Thanks Howard, Ill talk to my dad when he arrives on Saturday and see about moisture. I think a space heater of sorts could be work around (albeit costly with the energy prices these days!) ...Not keen on heat as an answer to damp problems, especially if it's an On/Off type. A tube heater that keeps the metalwork above the dew point is OK, but expensive to run. Condensation is the enemy. I suggest:

May not be too bad - cool sheltered workshops are less trouble than those that get hot and cold due to weather. Sheds are generally worse than outhouses, but much depends on position and insulation. Dave |

| Thread: Formatting a 3.5 ins Floppy - "Unable to complete the format Error" |

| 18/05/2023 17:17:03 |

Posted by Simon0362 on 18/05/2023 14:47:23:

Posted by SillyOldDuffer on 14/05/2023 09:53:37:

A late contribution, from me, but might be useful. ...

Dave, ummm....not entirely true....

If the FDC was instructed to write to a sector, it waggled the head and track lines to the drive and then read the headers until it the right sector, read through the header, waited until the data section marker and then splurged the data plus the updated CNC. A similar process for reading a sector. Some FDCs started reading from the index point, some just read and waited until the right sector came around. If you requested a quick format, I think they generally just set all header flags to ‘deleted’. A full format just rewrote everything. Macs were very different in that the FDC was much more controlling and I seem to remember that the entire track, headers and data, were sync’d from the index point and that (maybe) there was a physical feedback of the sector through their interface.

Hard drives of that era (ST506, ST412) followed the same logic and flow, it just happened a lot faster!

I spent nearly 10 years digitally emulating floppys, and a range of hard drives from those fitted to IBM PC-ATs through solutions attached to mini and mainframes as well as odd balls such as drums and core-stores…..fascinating stuff until SCSI came along and moved the intelligence to the drive. Yeah, I plead guilty to oversimplifying. In the early days, floppies were remarkably diverse, I think industry tried everything and I guess a long book could be written about them. Doesn't help that my memory is faulty. I worked with many early floppy systems and don't remember any of them being able to do a low-level format. I believe you - either I have brain fade or hadn't read the manual. Didn't work with drums myself, but the guys who taught me Data Processing had plenty of stories about them. Such as one escaping and terrorising everyone by running amok around the computer room! Dave |

| Thread: Free Scanner |

| 18/05/2023 16:53:49 |

Peter makes a good point about unnecessary obsolescence, but ask who pays our pensions, and where the money comes from? The dosh comes from an expanding economy that always has to sell more and more goods and services. At present, the game is compulsory, with severe penalties for failure. Consider the old Myford, an enterprise that earned a good living for half a century by making and selling lathes and accessories. Over time two threats appeared: one was competition from anyone selling a more modern and/or cheaper lathe; the other was that Myford lathes last a long time in amateur service, and were priced such that second-hand Myfords were more attractive to purchasers than new. The combination became a grievous assault on Myfords income. Companies exist to earn a profit, which pays wages, taxes, pensions, and more growth. As wealth is generated by economic activity if follows that anything that increases activity is good, and anything that decreases it is bad. Myford didn't find a way of increasing their income, and their people now do something else, that we hope is profitable, whatever it is. Standard right-wing thinking: the weak go to the wall. My mates in the old British Telecom were all made redundant by packet switching and fibre-optics. Although the payoffs were fairly generous, it was devastating to men aged 50 or so - too old to learn a new job, and too young to retire early. Brutal, but BT exists to make money, not to support a redundant workforce, One way of generating growth is ensure that products wear out or become obsolete. It's important that they be replaced. The system works well. Instead of manufacturing small numbers of expensive ivory handled razors, with stones and strops for rich folk and barbers, industry churns out millions of disposable safety razors that everyone can afford and use. Apart from barbers, everyone benefits even though a quality long lasting item was replaced by a cheap plastic consumable. And to rub it in, safety razors are made with between 1 and 5 blades, in various geometries, to suit different faces and beards - more choice. A selected safety razor shaves better than an expensive straight razor. Same principle is applied to cars, computers, TVs and pretty much everything else. As a result, prices are pushed down and the average standard of living increases. Sometimes, competition pushes quality up as well, but for price is more important for most commodity products. And there are always casualties, youngsters losing jobs, and old men discovering they can't talk to a Bank Manager, write cheques or pay cash. There's a flaw in continual expansion as a way of getting rich. It relies on the world having enough resources to maintain growth for ever, and on people not realising the bubble is going to burst. Therefore at some point in the future I expect the world to return to making expensive goods that last a long time. As this will be a major upheaval, it will have to be managed carefully, and it will be difficult. Get it wrong, and people will not only have to work years longer for a pension than we did, but their pension might not be worth anything when it arrives. Not impossible to manage diminishing resources, but it requires aggressive recycling, responsible consumption, and a shift to services rather than manufacturing as a source of wealth. And the transition could go bang because large numbers of people haven't understood what's going on yet, or accepted the trajectory, and would rather die in a ditch than reform. It's only human - everyone hates change. Dave

|

| Thread: A Leeuwenhoek microscope project |

| 18/05/2023 14:35:39 |

A traditional spring can be made from a length of Brass strip, which is usually annealed soft when new. Gently hammering the strip down to about ⅓rd thickness should work-harden it into a reasonable spring. Not like a proper steel spring, but good enough for this application. Now I want to make one, and I'm already far too busy! Dave |

| Thread: Workshop shelving |

| 18/05/2023 14:26:17 |

Posted by Thor 🇳🇴 on 18/05/2023 13:35:55:

I use the same kind of brackets as John, and use wood shelves. This system has served me well for decades. Thor Me too, except as a variant, I've found plastic guttering useful for holding stock rather than only fitting plain wooden shelves. Bit more fuss fixing the guttering in place, but it provides 2 or 3 shelves in one, in which I can separate longish lengths of Aluminium, Brass and Steel. Dave Edited By SillyOldDuffer on 18/05/2023 14:26:28 |

| Thread: What kind of steel is this? |

| 18/05/2023 14:18:01 |

Posted by Sonic Escape on 17/05/2023 22:36:11:

I don't plan to use this steel to anything important. Actually nothing that I do is important I thought it was interesting because it looks different from what I usually see in stores. And the fact that I paid only 4 euro for the whole bag was also a factor here. I don't have a way to heat it red hot. I doubt a barbeque fire would be enough. I started to read about different hardening methods and various types of steels. But it is a huge domain! It's interesting but I'll let it for later. To make things more complicated now I realized that HSS is not a single type of steel. I have one HSS tool, the left one in the video that has a silver color. The file slides on it without scratching it. I have also HSS tools that are black. Not on the cutting edge. I guess they oxidized or something. They can be scratched a little.

Yes - the important thing is to be aware of the possibility that not all metal cuts well. Apart from there being thousands of different alloys, metals can be heat-treated, work hardened, age hardened, and otherwise processed. Also possible a bar could be a composite, such as tool-steel enveloping a tougher core. Very confusing. I think what turns up as scrap depends hugely on where you live. The lucky ones live in places where scrap comes mostly from machine shops and structural work, and what they put in the bin is mostly suitable. However, if local industry specialises where you live, perhaps aerospace, military, food processing or making chemical componentry, the scrap could be downright unfriendly. My area has no industry to speak of, so the scrap comes from domestic sources and old cars. Here scrap metal is unpredictable, anything between wonderful and vile, mostly poor stuff. I've scrapped many a printer and scanner for the ground-steel runners inside. With one exception, they've all turned and cut beautifully. The exception looks identical to the others, but for some reason it's so hard that carbide struggles to cut it. Now I don't trust scrap at all. I mostly buy known metal. When tempted to use scrap because it's cheap, it's tested first. Any sign of trouble, such as a file bouncing off, or it work-hardening under a bluntish hacksaw, and I walk away. Almost the worst thing a beginner can do is persist with a nasty bit of scrap. Dave |

| Thread: Malicious website ? |

| 18/05/2023 13:46:30 |

Posted by Rooossone on 18/05/2023 12:31:52:

Ok having retried the specific URL in a safe location, it does get flagged for high risk of malware/malicious sources. ... If tested from a work computer, IT Departments almost invariably block anything on the internet that Downloads software. Unless they've made a mistake, or the job is done by the office-junior as a sideline. Businesses rarely take the risk of allowing employees to do whatever they want with a work computer: apart from the privacy issue, it reduces system reliability and makes diagnosing faults much harder. IT professionals go for tight configuration control! Dave

|

| 18/05/2023 13:23:03 |

Posted by Bob Unitt 1 on 18/05/2023 10:11:53:

Why would you trust an online website purporting to check other websites any more than you would trust any other online website ? Does not compute... Yes indeed, and "Quis custodiet ipsos custodes?" has always been a problem. (Who watches the watchmen?) Faulty logic as a reason for not bothering with deeper checking though. Even though security is never perfect, it's still prudent to do ones best. As far as I know, no-one has successfully faked a website security check website - yet. Not impossible, but a tricky challenge to pull-off for any length of time. The site I used lists the resources it uses, and they can all be verified individually. So if someone had successfully hijacked www.cnczone.com, they have to hijack URLVOID and it's sub-sources as well. That depth of deception is hard work. And if URLVOID is in doubt, other web check sites are available - Bill mentions Google Site Check. Security is a balance between inconvenience and safety. I try a notch or two harder than average, which is usually enough to stay one step ahead of evil-doers. Dave |

| Thread: Not Seen This One Before |

| 18/05/2023 12:53:40 |

Caught a bit of a fraud programme on Radio 4 driving home from mum's yesterday, worth a listen on iSounds. The bit I heard was about my most feared combination, which is fraudsters who've garnered enough personal information from the web to mount a convincing attack. Most spam email and phone calls are low threat because they're sent at random guessing the recipient might have an Amazon parcel on the way, or similar. Coupled with bad English, they're usually easy to spot. Targetted attacks are more dangerous, and possible because folk see no harm in putting personal information on the web, plus crooks work hard to harvest data from legitimate organisations. How about getting an email from a grandchild in trouble asking to be urgently sent money, and the request is bulging with correct family detail like nicknames, locations, and personal circumstances? Or your PC fires up with a message from the 'Microsoft Security Team', who when you ring them, speak perfect reassuring English - probably not a problem sir. However, they 'investigate' without asking for any private information, and 'confirm' in a fluster that your computer is transferring money out a bank account. They cause a panic by identifying the account with your correct name, account number and sort code. Unless you're authorising these transfers, they say, it's malware, and urgent action is needed to save the money, You must log on to your bank and immediately transfer the funds to holding account xx-xx-xx xxxxxxx, whilst they try and stop the virus. Don't get carried away! Ring up the granddaughter and don't do what they say - report the alleged problem to your Bank. No legitimate organisation ever asks customers to protect money by moving it to another account themselves. If asked to do that, it's a scam. When a bank finds out an account is compromised, they only have to lock the account : there's no need to move money. Nigel is right about little being done to stop the blighters! By value about half of all crime is Cyber-crime, and the police aren't resourced or organised to deal with it. Only about 1% of Cybercrime is prosecuted, and most isn't investigated. Almost none of the money is recovered. Given the scale of the problem, I'd expect a lot of policemen to be allocated, and that police forces would have specialists teams investigating. Nope - no money. A further problem is that UK police are set up to deal with crime in their area, and the system is less effective when criminals are located outside the region. Understandable when the criminal is in Timbuctoo and the victim in Plymouth, but worrying when the Devon and Cornwall constabulary can't get West Mercia to move. (And vice-versa) Unfortunately, staying outside a victims police region is easy for criminals on the internet. What's needed is a well-funded National Police cyber-crime unit, responsible for investigating and prosecuting all UK cyber-crime. The sort of police methods that deal well with a local solicitor defrauding his clients, don't touch the sides of this one. In the UK the problem became serious about 15 years ago, and - so far - the government hasn't gripped it. Reasons - it's expensive and difficult. Instead, the strategy has been to nudge financial institutions into preventing this type of crime. Not very successfully so far judging by the figures. Who loses after a successful fraud? Either the victim, or - if the bank accepts responsibility, then it's the banks other customers - everybody pays a little more for banking services. Spreading the pain over millions of customers makes it less obvious there's a big problem. However, I dislike the approach because it keeps cyber-crime safe for criminals! And easy ways of making money will always attract large numbers of new recruits, who in this case are allowed to hone their skills without the law intruding. Be careful out there! Dave

|

| Thread: Alibre - Have Taken The Plunge |

| 18/05/2023 11:00:34 |

Well done Nigel. My perception in this thread is you're very close to getting past the difficult bit, which is getting going in the first place. I had a difficult time starting too, but after the basics clicked in my mind, I made rapid progress. I suspect most failures to self-learn CAD fail in the early stages, and having a mentor on hand would quickly overcome that. If only! The alternatives are inferior. Though they've answered a lot of questions, I find it hard to follow blurry videos. Tutorials with screen-shots are better, but they don't help beginners get past subtle misapprehensions - things like accidentally snapping to the wrong point. Reference Manuals aren't teaching aids. AI could be the answer: software provided with CAD that's learned the rules and makes human-level sensible suggestions whilst the learner explores the software and follows exercises. AI could, for example, spot missed steps and incorrect clicking immediately during an exercise, just as a human expert would. Unlike CAD software itself, which can't tell the difference between a beginner going off the rails and an expert developing a complex part. Dave |

| Thread: Malicious website ? |

| 18/05/2023 09:59:58 |

Now then boys and girls, told that an AVM is red-flagging a website as a security risk, is it a good idea to rush in and try it? If the website is a wrong 'un, the bad guys may have put considerable effort into making it look and feel legitimate. You could be jumping into a honeypot. A second Charge of the Light Brigade. What does connecting to www.cnczone.com with a Browser prove? Almost nothing in a security sense, apart from the possibility of painfully finding your AVM is out-of-date compared to Keith's Norton. Better to check suspicious sites with one of the online checkers. I used **LINK** to scan www.cnczone.com. (Others available) It applied about 40 checks, which all came back clean, and provides other reassuring information. I'm 99% certain cnczone is safe. The remaining doubt is because of the unlikely possibility that Norton and Keith are one step ahead of everyone else! More likely it's a false positive: a mistake, or maybe www.cnczone.com was briefly spoofed or malfunctioned suspiciously recently, now fixed. Dave

Edited By SillyOldDuffer on 18/05/2023 10:01:06 |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in