Member postings for Nick_G

Here is a list of all the postings Nick_G has made in our forums. Click on a thread name to jump to the thread.

| Thread: Chuck size (good idea or not.?) |

| 01/08/2014 12:29:25 |

. Thanks SteveI you have given me some good information. I was wondering what the headstock taper was.?

Regards, Nick |

| Thread: Stuart D10 Metric Plans |

| 01/08/2014 11:25:46 |

Posted by Neil Wyatt on 01/08/2014 11:15:03:

I think we are missing the point. Stephen isn't asking HOW he just can't understand WHY Stuart don't revise their drawings. Neil

Fair point Neil. Perhaps someone should email them a link to this thread.?

Nick |

| Thread: Chuck size (good idea or not.?) |

| 01/08/2014 10:43:35 |

. Thanks for the replies guys. Yes I know it will not be a cheap option buying a semi finished quality D1-3 backplate. The Bison 100mm one is over £100 then plus the cost of the 80mm Pratt Burnerd will take it into the region of a readily manufactured Pratt 125mm with a D1-3 fitting. - But nothing of quality is cheap when it comes to engineering it seems. Yes I have considered a collet chuck as an option but as Neil says I will get more use from the 80mm scroll I think. So that will go on a future 'wish list' SteveI :- The STS 10-20 Boxfords spindle bore is 38mm / 1 1/2" not 1" Many thanks again for the replies

Nick

Edited By Nick_G on 01/08/2014 10:44:31 |

| 01/08/2014 01:12:52 |

. The D1-3 fitting 125mm Pratt Burnerd on my Boxford has seen better days.! It's usable, and there is lots more that I would prefer to spent the money on, but I feel it needs to be replaced. I am considering purchasing a smaller chuck.! ( I can always fit the 125mm back in seconds if needed ) Possibly a Pratt Burnerd 80mm. My logic behind this (possibly flawed) is that a lot of the smaller parts seem to get swamped by the 125mm one and thus an 80mm will suit my purposes better. The 80mm has a bore of 19mm so will pass most things needed to be turned for a Stuart type engine. Other things will be turned in my 4 jaw or on a faceplate, and as I said the 125mm could always be fitted back if needed. So is buying new 80mm a good idea or shall I replace it with another 125mm.?

Cheers, Nick

|

| Thread: Stuart D10 Metric Plans |

| 01/08/2014 00:38:06 |

. This :- (iPhone app or similar)

Plus :-

Plus :-

Plus :- Half an hour with the drawing and it was all sorted for my Stuart James Coombes. While doing it I was familiarising myself with the general layout of the engine, which I imagine is time most people spend anyway.!

Nick |

| Thread: Quick Change Tool Post |

| 30/07/2014 10:15:16 |

Posted by Oompa Lumpa on 30/07/2014 09:48:23:

The problem with the Myford one - from RDG - is the lack of toolholders. They have been "coming into stock" for the last six months.

I have the same problem with one for a Boxford that I got from them.

Nick |

| Thread: Kit build suppliers |

| 29/07/2014 16:09:29 |

Posted by Brian Wood on 29/07/2014 16:01:56:

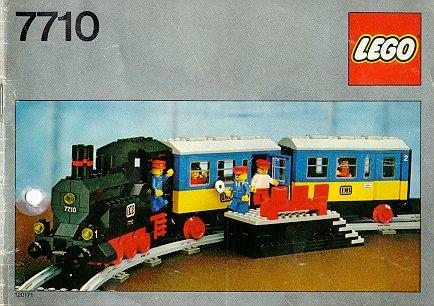

P.S Nick My friend is a little beyond Lego choo choos now, it was a serious question.

I realised that. Hence the string of

Nick |

| 29/07/2014 09:47:45 |

.

Nick |

| Thread: Stuart D10 Metric Plans |

| 29/07/2014 09:28:23 |

. I may be wrong on this but I 'think' all Stuart plans are still in imperial. I say this as I very recently bought a set for a James Coombes engine and they are imperial.

Regards, Nick Edited By Nick_G on 29/07/2014 09:28:52 |

| Thread: Avoiding marks on work.? |

| 26/07/2014 19:48:21 |

. Cheers for the replies guy's So shims it is then.!

Nick |

| 26/07/2014 06:20:57 |

. Any tips on how to lower the chances of leaving marks from a chuck on semi finished items.? Obviously one would ideally finish the job with just one chuck clamping. But of course this is not always possible is it. Sometimes the part has to be turned around. So taking aside the obvious of not swinging on the chuck key like Thor, using soft jaws, collets etc, etc what tips do others have for lowering the chances of leaving witness marks from chucks on the work. Is it shims of brass, aluminium or are there any brands of tape that are helpful in assisting.

Cheers, Nick |

| Thread: ER40 collet chuck D1-4 |

| 23/07/2014 13:45:19 |

. I was only the other evening watching on youtube a short video about the Jacobs one. I found it quite interesting. I am left wondering though if it was the cost of these or them not working as specified that has not made them more popular. Here is the link to youtube :- **LINK**

Regards, Nick |

| Thread: Boxford drive belt |

| 21/07/2014 21:32:42 |

. Thanks for the reply Bob. I do know the size of the existing belt but I was wondering if the linked belt may be an improvement in decreased vibration.

Regards, Nick |

| 21/07/2014 17:58:44 |

. I have a Boxford lathe and the drive belt looks to have seen better days (bit like me. I have seen various mentions that 'linked belts' are good performers and a worthwhile upgrade to some machines. - So would such a belt (see pic) be suitable for my Boxford or would I also need to change the pulley's.? The existing belt is a 10mm width V belt. i.e. this type of belt (10mm Z section) :-

On this :-

Cheers, Nick Edited By Nick_G on 21/07/2014 18:00:45 |

| Thread: Sherline chuck. |

| 19/07/2014 20:47:38 |

. At a guess. As the lathe (looking at the chuck face) spends the the vast majority of it's time running anti-clockwise I would say the chuck also unscrews anti-clockwise.

Nick Edited By Nick_G on 19/07/2014 20:48:36 |

| Thread: Old Mill Problem (electrical) Help |

| 19/07/2014 20:38:43 |

Posted by Clive Foster on 19/07/2014 19:57:55:

Although £85 seems a lot for a manual if it is the correct one then, from a commercial perspective, its worth it to make fixing a simple read value, purchase and solder in job. Clive

I agree.

Nick |

| 19/07/2014 17:07:48 |

. Hi Les, I am in Warrington. - The machine is between Warrington and St Helens.

Cheers, Nick

|

| 19/07/2014 10:44:53 |

. Hello peoples, I wonder if you can help me help a friend. A long standing friend of mine has a small jobbing workshop and has a problem with an old mill. Most of his mills are Bridgeports but this one is of Polish origin. Basically there is a problem with the control circuit.! The machine and it's motors are 3 phase but as is quite common the control circuit voltage is lower. There is a resistor on the control PSU (seems to be a wire wound one) that has burnt out rendering the machine inoperative. (motors spin up fine if the contactors are manually 'pushed in' ) The machine plate says the control voltage is 220 volts, but I am not sure if this is AC or DC as there are diodes on the PSU that may be configured into a bridge to render the supply into DC So what I am after is a circuit diagram that will hopefully tell me what value the burnt out resistor was and give me an overview of how the machine is configured electrically. - Does anybody know where I could get such.??? I am attaching photos that I took with my phone to help with its ID and for the general interest of others. (spot the Myford dumped at it's base in one of the pics) Denis tells me that although old the machine is a good solid and accurate piece of kit. He is obviously reluctant to trade it in for scrap value for what seems to be a minor issue. Thanks, NIck

|

| Thread: One Man and His Lathe |

| 15/07/2014 21:55:21 |

. Me being a beginner un-all and having recently purchased and installed a lathe I am wondering if my opinion in an article may be of interest.? What I did and probably of more interest what I would not do again.!! Or is it articles from the seasoned and accomplished you require.?

Nick |

| Thread: Article on Tungsten - Worth a read. |

| 12/07/2014 09:19:13 |

. On BBC website here :- **LINK**

Nick |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

.jpg)

Register

Register Log-in

Log-in