ArcEuro Model 100 QCTP on a Myford ML7?

| Jon Gibbs | 30/05/2014 08:52:49 |

| 750 forum posts | Has anyone fitted one of these to their Myfords who might have some advice before I splash-out please? It looks as if "all" I need to do is to replace the Myford's 7/16 BSF toolpost bolt with an M14x1.25 one, but I am a bit reluctant to enlarge the hole in the top-slide to 14mm. Am I being too precious? Is there a satisfactory way to keep the hole at 7/16 so that it can be returned to original and yet have a sturdy enough M14 thread above? I thought about a shouldered stud coming through the topslide 7/16 hole with say a M8 threaded section which would screw into the M14 rod but obviously it'd need to be locked in some way to prevent it coming undone and would that ever be satisfactory really? Any advice gratefully accepted. Jon |

| Brian Wood | 30/05/2014 09:03:22 |

| 2742 forum posts 39 photos | Hello Jon, The Myford toolpost stud is flanged on the underside and secured from rotation by a peg. I don't think your answer lies with a simple replacement threaded bar.unless you duplicate the flanged feature as well. Why modify? I'm sure a trawl on ebay will find a genuine 7/16 fitting version and leave the lathe unaltered. Regards Brian |

| Neil Lickfold | 30/05/2014 09:14:46 |

| 1025 forum posts 204 photos | For my one, I made a delrin bush that fits snug in the bottom of the tool block, and has drag on the bottom of the original pin. I made a stepped washer for the top. The best part is, that due to the snugness of the delrin bush, when I rotate the tool post or need to clock it in, it rotates and pivots without the issues of the standard clearance tool posts.

|

| Jon Gibbs | 30/05/2014 09:52:07 |

| 750 forum posts | Thanks Brian, Sorry, I should have said that I know how the original 7/16 bolt is fixed and I would be aiming to reproduce the flange and pin with any new solution. The problem I see is that the ArcEuro version requires a longer threaded bar to allow for the piston handle on top. I'm pretty sure that the original 7/16 bolt would be too short. I have looked for other variants with a 7/16 hole and they seem to be of the Myford QCTP pattern which looks noticably cruder to me than the Arc version which seems closer to the Aloris? Nick, Thanks for the suggestion. I'm not sure I follow how the delrin bush can come into contact with the pin on the underside of the topslide casting. What am I missing please? Many thanks Jon Edited By Jon Gibbs on 30/05/2014 09:52:54 |

| Clive Foster | 30/05/2014 10:24:14 |

| 3630 forum posts 128 photos | The whole point of the Myford design is to avoid a relatively weak and shallow thread in cast iron. It also spreads the loading somewhat reducing distortion tendencies. Assuming you have a suitable tap and the lengths work correctly so the internal and external threads don't overlap the minimum change option would be a tube nut having an internal 7/16 thread to suit the Myford stud and external 14 mm thread for the QCTP. Ideal would be to have the tube going right down to the top-slide so that it locks up directly but that would probably need an unfeasibly long tap so an intervening spacer would be required. I'd silver solder a separate spacer to the nut to improve rigidity. Tube and spacer being a decently snug fit in the tool post. If modifications to the slide are acceptable a good approach would be to copy Smart & Brown and use a steel top hat bush screwed to the base of the top-slide and finishing flush with the upper surface with a suitable internal thread for the pin of whatever size seems sensible. Standard 7/16 is probably as good as any. Proper shoulder on the stud so it screws down solidly onto the bush. Reverting to standard simply means changing the 14 mm - 7/16 stud for a 7/16 - 7/16 one. Clive |

| JohnF | 30/05/2014 10:27:38 |

1243 forum posts 202 photos | Jon, why not just buy the Dickson type tool post from Myford and you can be sure it will fit ora try I think R & D Precision? Who we're making a high quality tool made in the UK. I don't have all the dimensions for the Arc post but it looks to have a recess sin the bottom and this may put additional unnecessary stress on the top slide, these are not very thick around the stud. As far as the hole- stud size goes all you need is a top hat spacer under the locking nut on top of the tool post. i have original Myford Dickson tool posts on my lathe's and they have served me well for over 40 years plus I have been using this type of tool post since they were introduced in the 1960's John |

| Jon Gibbs | 30/05/2014 11:18:54 |

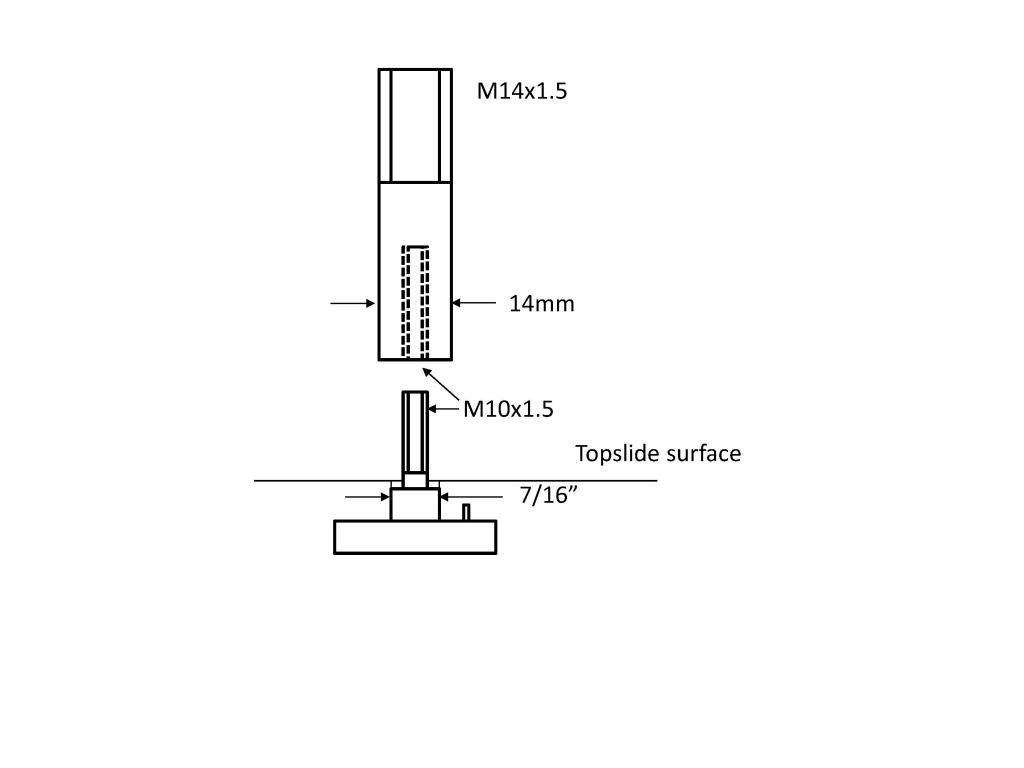

| 750 forum posts | Thanks for the suggestions. Based on Clive's description I sketched this out - obviously not to scale. Would this work do you think?

I know that the Myford/Dickson QCTP and clones of it are always an option but does seem that it is compromised by the height of the standard 7/16" stud, isn't it? Has anyone tried this before me? Many thanks Jon Edited By Jon Gibbs on 30/05/2014 11:21:21 |

| Dullard Ard | 30/05/2014 12:12:47 |

| 16 forum posts | AFAIK you can make the toolpost fit .....but the issue then is can you get your tooling low enough in the AXA holder? as they have a substantially thicker base than say a Dickson type. Dull |

| Neil Lickfold | 30/05/2014 13:16:34 |

| 1025 forum posts 204 photos | Sorry, Mine is the Dickson Type. It used to be a 4 way tool block with a sprag type of arrangement that allowed it to index every 45 degrees. I removed that little block screws and pin, and replaced it with the Dickson type setup. I did have the Axa type but it was too thick in the holders to get tools to the correct centre height. It just gathers dust for another project oneday. I will take some pics of what I have done if that is of any help and try to post them tomorrow if all is well. Neil

|

| Ketan Swali | 30/05/2014 13:41:37 |

| 1481 forum posts 149 photos | Hi Jon, Unable to go into specifics...purely because I dont know...but speaking with several Myford owners over the years, it would seem that the Model 100 QCTP is simply too big for the Myford ML7, S7, even if you solve the stud problem. In short, I would suggest that you consider the other options being presented here, based on the responses I have had over the years. Unfortunately, we have not really gone down the road of suitability for use with Myford lathes. Ketan at ARC. |

| Jon Gibbs | 30/05/2014 17:18:59 |

| 750 forum posts | Hi Ketan, Ahhh, that settles it then! Thanks very much for saving me the trouble and thanks to all for the replies. Looks as if it'll have to be the Dickson QCTP then. Jon |

| MattK | 30/05/2014 18:23:17 |

39 forum posts 7 photos | +1 for the A&R toolpost and holders. Well made bit of kit. I know they sell on ebay occasionally and better quality than the Chinese clones (I have a few of these holders too). He's got some nice rear toolpost sets on fleabay now. |

| RobC | 31/05/2014 16:58:11 |

| 54 forum posts 3 photos | Alternatively, Rotagrip do some Dickson styles which are small enough for the Myfords. I had one from them after the third return of an Indian/Chinese variant to the supplier! |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in