Further Adventures with the Sieg KX3 & KX1

A thread for new owners of these machines to post in.

| Ian Johnson 1 | 09/04/2020 19:34:56 |

| 381 forum posts 102 photos | Posted by Sarah on 09/04/2020 17:46:59:

Hi Ian, Would you be able to let me have your settings please 😊 The pulse settings changed them selves from 4us to 3us after I increased the velocity, which then put the speed back down. Jus coildnt get them to change back to 4us.

Thanks. Edited By Sarah on 09/04/2020 17:47:44 Yes I'll have a look for you Sarah probably tomorrow because I've got a virtual pub quiz to take part in tonight! |

| Sarah | 09/04/2020 19:37:30 |

| 27 forum posts 4 photos | Posted by Ian Johnson 1 on 09/04/2020 19:34:56:

Posted by Sarah on 09/04/2020 17:46:59:

Hi Ian, Would you be able to let me have your settings please 😊 The pulse settings changed them selves from 4us to 3us after I increased the velocity, which then put the speed back down. Jus coildnt get them to change back to 4us.

Thanks. Edited By Sarah on 09/04/2020 17:47:44 Yes I'll have a look for you Sarah probably tomorrow because I've got a virtual pub quiz to take part in tonight! I hope you enjoy your virtual pub quiz, I hope the beer is not virtual 😉

Best wishes, Sarah |

| Adam Stevenson | 09/04/2020 19:42:28 |

| 35 forum posts 1 photos | Try setting it to 5us and the computer will round it down to 4us. They were only rated for 5,000 due to stepping issues. It is down to the PC putting enough steps, both high and low, to drive the spindle at the speed. |

| JasonB | 09/04/2020 19:46:21 |

25215 forum posts 3105 photos 1 articles | Adam, Sarah has a KX1 so should be good for 7000? |

| Adam Stevenson | 09/04/2020 19:58:28 |

| 35 forum posts 1 photos | Machine yes it will work with good feed rates and tooling but it is the computers that caused the bigger issues we had with support. Entering a 5us might round down because of PC maths working fine while the tuning wizard is open but rounds down when the window closes. |

| JasonB | 10/04/2020 10:32:22 |

25215 forum posts 3105 photos 1 articles | Just put the infra-red tacho onto mine, all very close except at 4000rpm which was a bit off 5K = 5009 4K = 4170 3K = 3030 2K = 1995 1K = 1017

This is the tuning screen settings are as it came to me. click to see larger

Edited By JasonB on 10/04/2020 10:32:39 Edited By JasonB on 10/04/2020 10:36:18 |

| Adam Stevenson | 10/04/2020 10:52:55 |

| 35 forum posts 1 photos | Hi Jason, are you using a USB breakout board? |

| JasonB | 10/04/2020 12:56:54 |

25215 forum posts 3105 photos 1 articles | Yes, mine was one of the last ones Ketan had. |

| Adam Stevenson | 10/04/2020 13:22:26 |

| 35 forum posts 1 photos | Ah so the step and dir pulse don't matter, as the breakout has an on-board timer, and they only change a parallel port output. The 4,100 is OK, you can try a few about that speed as it might be a tacho blip point, the reason we used to say 100 rpm at 5,000 was fine. |

| Ian Johnson 1 | 10/04/2020 17:26:00 |

| 381 forum posts 102 photos |  Posted by Sarah on 09/04/2020 19:37:30: Posted by Sarah on 09/04/2020 19:37:30:

Posted by Ian Johnson 1 on 09/04/2020 19:34:56:

Posted by Sarah on 09/04/2020 17:46:59:

Hi Ian, Would you be able to let me have your settings please 😊 The pulse settings changed them selves from 4us to 3us after I increased the velocity, which then put the speed back down. Jus coildnt get them to change back to 4us.

Thanks. Edited By Sarah on 09/04/2020 17:47:44 Yes I'll have a look for you Sarah probably tomorrow because I've got a virtual pub quiz to take part in tonight! I hope you enjoy your virtual pub quiz, I hope the beer is not virtual 😉

Best wishes, Sarah Hi Sarah here is a photo of my KX1 Z motor drive settings. (Edited to include the photo above which I forgot to post! ) Steps per = 500 Velocity = 1000.2 Acceleration = 100 G's = 0.0101976 Step pulse = 0 Dir pulse = 0

A little bit different from your settings. No idea if they are the 'correct' settings but they seem to work okay. It's a USB KX1 by the way if that makes any difference?

Oh and I got 25 out of 50 in last night's virtual pub quiz 😁 Ian Edited By Ian Johnson 1 on 10/04/2020 17:28:57 |

| JasonB | 10/04/2020 19:56:16 |

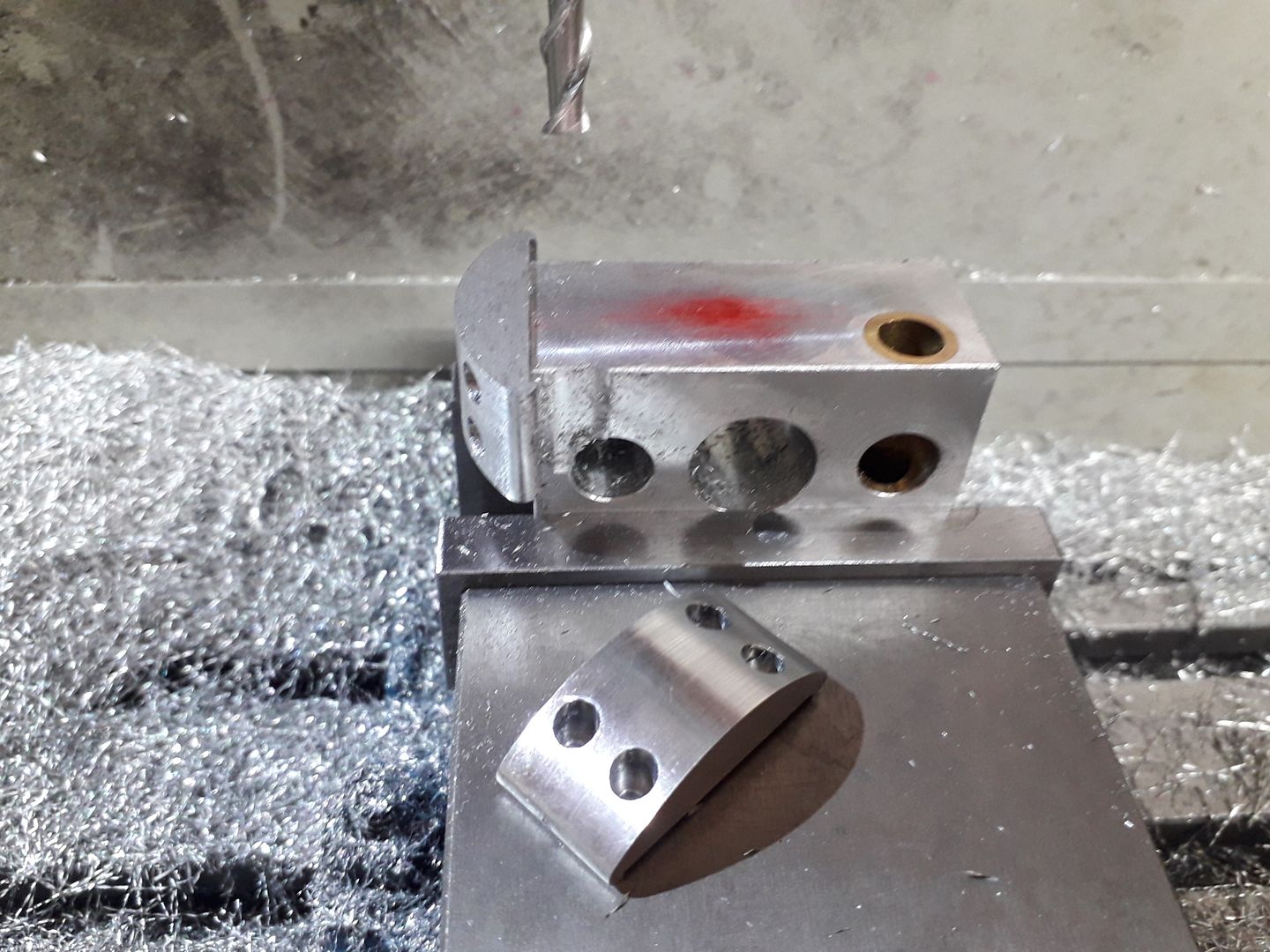

25215 forum posts 3105 photos 1 articles | Another bit of profiling with the work screwed to some scrap for you Sarah. The counterbored holes that will take short lengths of rod on the finished part were used to hold the work with M2.5 cap head screws. The profile has 2mm radius at each end of the main 25mm radius which was cut at the full 16mm height with one of ARCs long series HSS aluminium specific cutters, this time run at 5000rpm, 0.4mm DOC rouging and 0.2mm finish pass all at 250mm/min all climb cutting

|

| Martin Connelly | 10/04/2020 20:19:47 |

2549 forum posts 235 photos | Sarah, is it possible that the pulley settings are limiting the maximum spindle revs. If you are not using the pulley settings anywhere just set the max in all of them above what you are ever going to run at. Martin C |

| Sarah | 12/04/2020 09:37:33 |

| 27 forum posts 4 photos | Hi Guys, Thank you for the photographs of your spindle settings, your figures are very different to each others and also to mine as well. I've added a photo of mine below. The three machines are: Steps per. Velocity. Acceleration 1. 120. 4 500. 1000.2. 100 100. 6000. 500

A few questions for you if you don't mind. I understand what 'Steps per' do on the X, Y, Z axis relating to the stepper motors and ball screw drives, but what does it do on the Spindle Speed and why are our three machines so different?

Why are the Velocity and Acceleration figures also so different for the three machines?

I removed Mach3 and the Sieg setup files from my PC, then installed them again to make sure I had the default setting. If I go into the Motor Tuning screen, don't change anything and exit by just closing the X on the top right of the screen the Step Pulse won't change from 4us. However if I go into the Motor Tuning screen and click on the OK button to leave the screen, then when I go back into the Motor Tuning screen again it has changed to 3us. It will retain a value of 3us and 5 us. When it does change the Step Pulse to 3us, or a value of 5us, this changes the value for the X, Y and Z axis as well and changes how the axis are driven. Will driving the X, Y and Z axis at 5us cause any problems?

I can match the measured and demanded spindle speeds if I do change the Step Pulse to 5us, but I'm wary of changing bits I don't really understand.

Thanks for the video's and pictures of your work on your machining, giving me a good idea of what to do. I'll post some of mine soon hopefully. I wouldn't have thought of fixing a bit to be machines to the side of a chunk of aluminium, it will make a bit I need to machine a lot easier thanks.

I appreciate your help, hope I'm not asking too many questions, I'm just eager to learn.

Best wishes, Sarah

Edited By Sarah on 12/04/2020 09:38:58 Edited By Sarah on 12/04/2020 09:41:50 |

| JasonB | 12/04/2020 10:10:52 |

25215 forum posts 3105 photos 1 articles | Sarah, going by what Adam (Son of the late John Stevenson) said both mine and Ian's are connected by USB so our speeds are controlled differently to your earlier parallel port machine which is why I have nothing on the spindle screen and would think Ian's would be the same though he only showed the X axis.. |

| Sarah | 12/04/2020 10:23:58 |

| 27 forum posts 4 photos | Posted by JasonB on 12/04/2020 10:10:52:

Sarah, going by what Adam (Son of the late John Stevenson) said both mine and Ian's are connected by USB so our speeds are controlled differently to your earlier parallel port machine which is why I have nothing on the spindle screen and would think Ian's would be the same though he only showed the X axis.. Hi Jason, I think Adam said the timing was controlled differently, but are the Steps Per, Velocity and Acceleration still adjustable from the Motor Tuning screen? I've been doing a lot of reading on line but not found enough out unfortunately. I've got a friend getting me some aluminium offcuts from work which will be very useful for mounting bit to 😊

Regards, Sarah |

| Adam Stevenson | 12/04/2020 10:32:46 |

| 35 forum posts 1 photos | Hi Sarah, if you have a parallel (25 pin D connection) Then the pulse will matter as it is common on all motors, USB have in B type and us an internal timer to control the pulse. The SIEG needs about 5us step pulse for the spindle to drive the motor tacho controller, the Axis motor drivers will run on a smaller step pulse but as they are all the dame value setting it to 5us will be fine. Some computers even needed 6 or 7 depending on the motherboards. Below is the spindle tuning picture from the old web site for support, so are what the machines are set at and the one you need to change shown using the formula. (Required Vel) = [Required RPM] X [current Vel] / [Measured RPM] So if you are setting the speed to 1,000 and getting 1,234 RPM with the default 4,000 Vel you set it to 3241.49 Vel |

| Adam Stevenson | 12/04/2020 10:49:12 |

| 35 forum posts 1 photos |

|

| Sarah | 12/04/2020 12:13:13 |

| 27 forum posts 4 photos | Hi Adam, What effect does varying the Steps per value? I can understand it's use with stepper motors, but not with a brushless motor.

Regards, Sarah |

| Adam Stevenson | 12/04/2020 13:13:25 |

| 35 forum posts 1 photos | It was found to be 350 for best results, the velocity is the one important for the spindle. Lots of testing was done with these machines and each one from Arceuro was calibrated to allow a quicker setup by the users. The actual values are regardless it is the ratio between them that matters. Think that for each 360º the computer sends steps, it is not just how many steps are sent but how fast the amount are sent too. But we are not sending steps but a Voltage that the controller uses to drive the motor at a set speed, they is also a in-built tacho that will increase or decrease the current to keep the speed constance. So at the end it is not the number of steps sent per revolution but the rate at which they are sent. So we pick a nice number and then how fast we send them and balance the ratio between them, in this case 350 x 4,000 or 35 x 40,000 or 3,500 x 400. The computer will have limits so we picked the mid ground that most PC's would work with. Edited By Adam Stevenson on 12/04/2020 13:16:52 |

| Ian Johnson 1 | 12/04/2020 13:25:13 |

| 381 forum posts 102 photos | Hi Sarah I just realised that I gave you the Z axis motor info not the spindle motor info duh! So here is my spindle motor info for my KX1 Steps per = 1 Velocity = 120 Acceleration = 4 G's = 0.0004079 Steps pulse = 0 Dir pulse = 0

Same caveats apply, they work okay on my machine and I am useless on computer stuff! |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

![20200410_103408[1].jpg 20200410_103408[1].jpg](/sites/7/images/member_albums/44290/856543.jpg)

![20200410_095720[1].jpg 20200410_095720[1].jpg](/sites/7/images/member_albums/44290/856540.jpg)

Register

Register Log-in

Log-in